-25-

Electrical Adjustments

1. Receive the 16-step grey scale computer signal with

Computer1 [RGB]

mode.

2. Enter the service mode

3. Connect a digital voltmeter to test point “

TPGV1

” (+)

and chassis ground (-).

4. Select item no. “

1

” and change data value to adjust

the voltage to be

7.0

±0.05V.

5. Connect a digital voltmeter to test point “

TPRV1

” (+)

and chassis ground (-).

6. Select item no. “

2

” and change data value to adjust

the voltage to be

7.0

±0.05V.

7. Connect a digital voltmeter to test point “

TPBV1

” (+)

and chassis ground (-).

8. Select item no. “

3

” and change data value to adjust

the voltage to be

7.0

±0.05V.

9. Connect a digital voltmeter to test point “

TPGV2

” (+)

and chassis ground (-).

10. Select item no. “

21

” and change data value to adjust

the voltage to be

8.0

±0.05V.

11. Connect a digital voltmeter to test point “

TPRV2

” (+)

and chassis ground (-).

12. Select item no. “

22

” and change data value to adjust

the voltage to be

8.0

±0.05V.

13. Connect a digital voltmeter to test point “

TPBV2

” (+)

and chassis ground (-).

14. Select item no. “

23

” and change data value to adjust

the voltage to be

8.0

±0.05V.

m

Video Center adjustment

1. Receive the 16-step grey scale computer signal with

Computer1 [RGB]

mode.

2. Enter the service mode.

3. Connect an oscilloscope to test point “

TPVIDEOG

”

(+) and chassis ground (-).

4. Select item no. “

10

” and change data value to adjust

amplitude “a” to be

10.0

±0.1V.

5. Connect an oscilloscope to test point “

TPVIDEOR

”

(+) and chassis ground (-).

6. Select item no. “

11

” and change data value to adjust

amplitude “a” to be

10.0

±0.1V.

7. Connect an oscilloscope to test point “

TPVIDEOB

”

(+) and chassis ground (-).

8. Select item no. “

12

” and change data value to adjust

amplitude “a” to be

10.0

±0.1V.

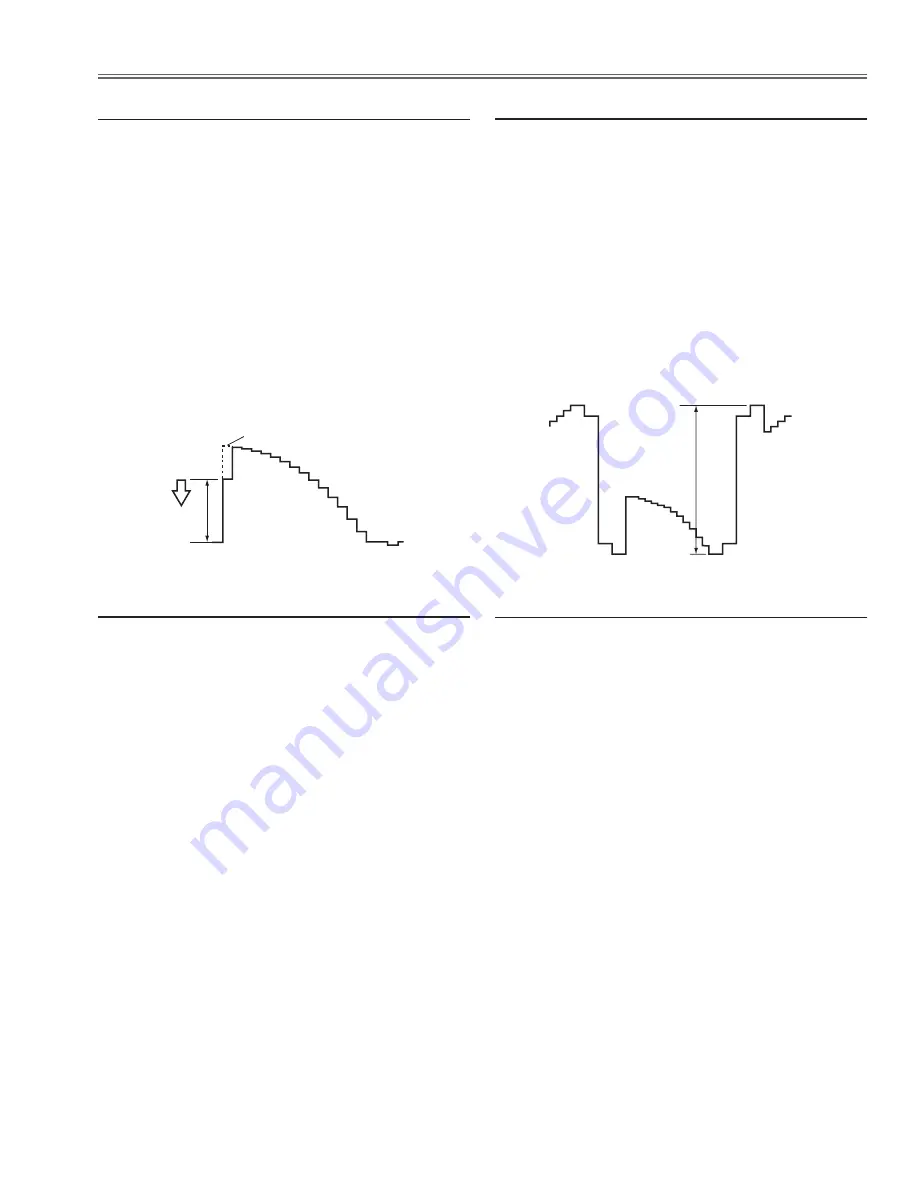

(a)

black level

black level

,

Black Reference adjustment

1. Receive the 16-step grey scale 1080i component

video signal with

Computer1 [Component]

mode.

2. Enter the service mode.

3. Connect an oscilloscope to test point “

TPVIDEOG

”

(+) and chassis ground (-).

4. Select item no. “

7

” and adjust the amplitude “a” to be

minimum

by changing the Data value.

5. Connect an oscilloscope to test point “

TPVIDEOR

”

(+) and chassis ground (-).

6. Select item no. “

8

” and adjust the amplitude “a” to be

minimum

by changing the Data value.

7. Connect an oscilloscope to test point “

TPVIDEOB

”

(+) and chassis ground (-).

8. Select item no. “

9

” and adjust the amplitude “a” to be

minimum

by changing the Data value.

(a)

White Level

n

Gain adjustment [Component-1080i]

1. Receive the 1 line black/white pattern computer sig-

nal with

Computer1 [RGB]

mode.

2. Enter the service mode.

3. Project only green light component to the screen.

4. Select item no. “

13

” and change data value to obtain

the minimum flicker on the screen.

5. Project only red light component to the screen.

6. Select item no. “

14

”” and change data value to

obtain the minimum flicker on the screen.

7. Project only blue light component to the screen.

8. Select item no. “

15

and change data value to obtain

the minimum flicker on the screen.

.

Common Center adjustment

Summary of Contents for 1 122 280 00

Page 50: ... 50 IC Block Diagrams BA7078AF Sync Detector IC5301 AN5870SB RGB SW G_Sync Separator IC5201 ...

Page 51: ... 51 IC Block Diagrams BA9743AFV DC DC Converter IC371 FA5502 P F Control IC621 ...

Page 52: ... 52 IC Block Diagrams LM4889M Audio Amplifier IC5031 PW168A Scaler Main CPU IC301 ...

Page 53: ... 53 IC Block Diagrams NJW1141 Audio Selector IC5001 STR Z2156 Power Switching Control IC631 ...

Page 78: ...MM5 XU4700 78 L2 Prism LCD panel Ass y Mechanical Parts List L2 c L2 a L2 b L2 e L2 d L2 ...

Page 79: ...MM5 XU4700 79 Mechanical Parts List A D D E B C C L19 L13 L5 L8 L18 L11 L1 L3 L7 L12 L6 L14 ...

Page 82: ... MM5A Oct 2004 BB 400 Printed in Japan SANYO Electric Co Ltd ...

Page 86: ...Diagrams Drawings MM5 XU47 ...