- 4 -

5. Method of operation

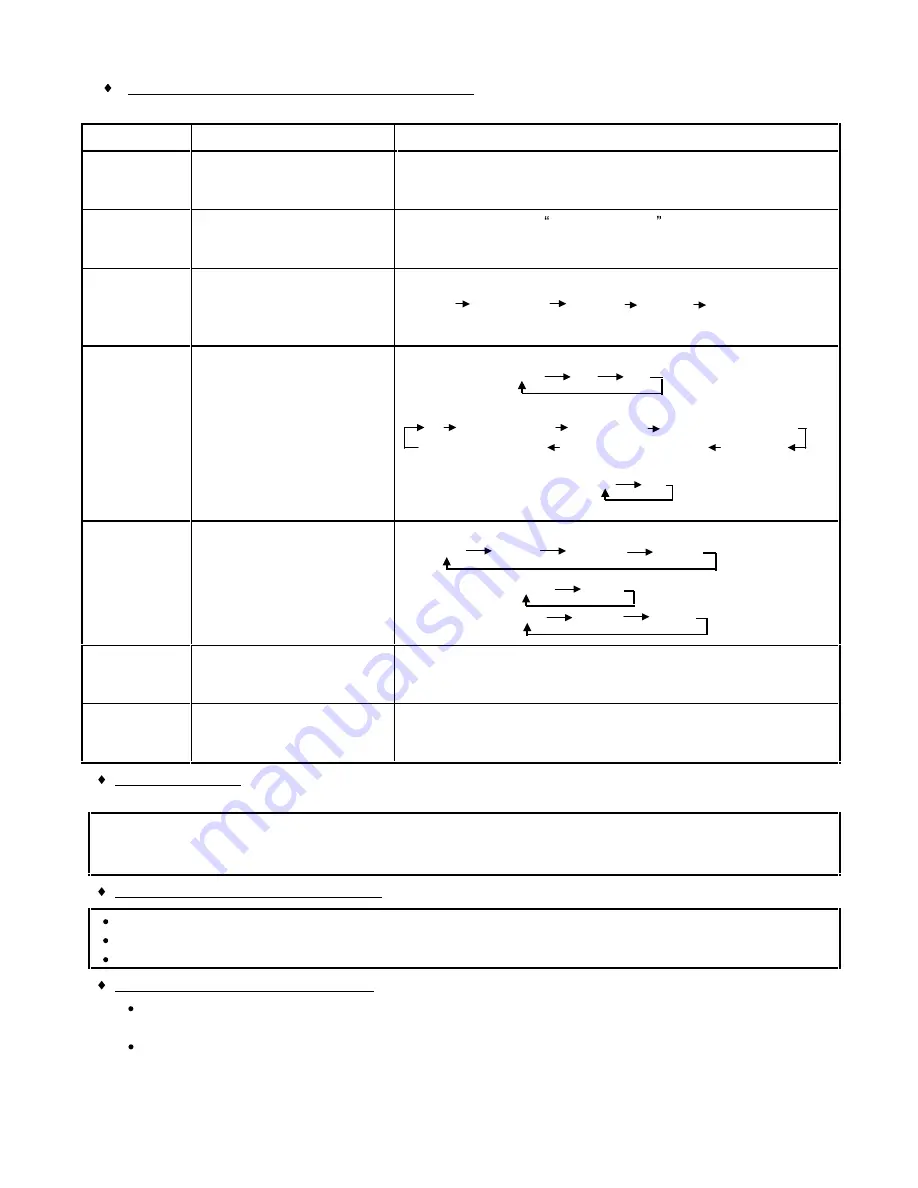

Name and function of buttons on control panel:

When you press those buttons, the setting program and indicators (LED) will change alternately.

BUTTON

SETTING PROGRAM

INDICATION OF LED

POWER

SWITCH

To turn the power ON and

OFF alternately.

When you press the power switch to turn power ON, NORMAL

indicator will light up. When power is turned off, NORMAL

indicator will black out.

START/PAUSE

Start or temporarily stop

wash operation.

When you press the START/ PAUSE button to start, the

indicator of the first process will blink. When pausing, LED

indicator will light up.

ONE TOUCH

SELECT

Choose the desired washing

program : Normal, Heavy

Duty, Custom, Blanket, Dry

Care.

Normal Heavy Duty Custom Blanket Dry Care

SELECT/ SET

Used to set a variety of

wash programs.

To preset the finish time,

washing time, rinsing mode

and spinning time.

Setting Washing time:

OFF 1 12

Setting Rinsing mode:

0 1(water saver) 1.(overflow) 2(twice water saver)

3.(3times overflow) 3(3times water saver) 2.(once

Setting Spinning time: 0 10

WATER

LEVEL

Select the appropriate water

level that matches the load

volume. When this button

pressed, water level will be

changed alternately: HIGH,

MED, LOW 2 , LOW 1.

Normal/ Heavy Duty/ Custom course:

HIGH MED LOW 2 LOW1

Blanket: HIGH MED

Dry Care: MED HIGH LOW2

OPTION

Used to set a variety of

Soak program and Soft Spin

program

While selecting the option function, the indicator will light up.

If the option function is not selected, the indicator blacks out.

CHILD

SAFETY

Press the water level button

for 4 seconds to choose

desired child safety.

When this function is selected, Washing course will stop if

Washer Lid is opened 5 seconds or more during washing.

Signals of buzzer:

Buzzer will sound in the following cases :

The button is pressed :

Buzzer sounds beep in 0. 6 second.

Washing cycle end

:

Buzzer sounds with beep tone ON -0.5 second & OFF- 0.5 second for 6 seconds.

Have a trouble

:

Buzzer sounds with beep tone ON -0.3 second & OFF -0.3 second in 16 times.

How to cancel the cycle end buzzer :

Deleting : Turn on the POWER SWITCH and hold down the START / PAUSE button for 4 seconds.

Resetting : Turn on the POWER SWITCH and hold down the START / PAUSE button for 4 seconds.

In both cases, buzzer will sound to indicate that the program has been set.

About Automatic turn off function :

If you leave the washer turned on without starting the operation, the Power Switch will turn off

automatically after 10 minutes.

When washing operation finished, the POWER SWITCH will turn off in 5 seconds automatically.

once

overflow)

Summary of Contents for ASW U1100T

Page 4: ... 3 4 Electric circuit diagram For the purpose of safety please use only designated parts ...

Page 22: ... 21 14 Exploded View ...

Page 23: ... 22 ...

Page 24: ... 23 ...

Page 25: ... 24 ...