Service Manual

FILE NO.

I

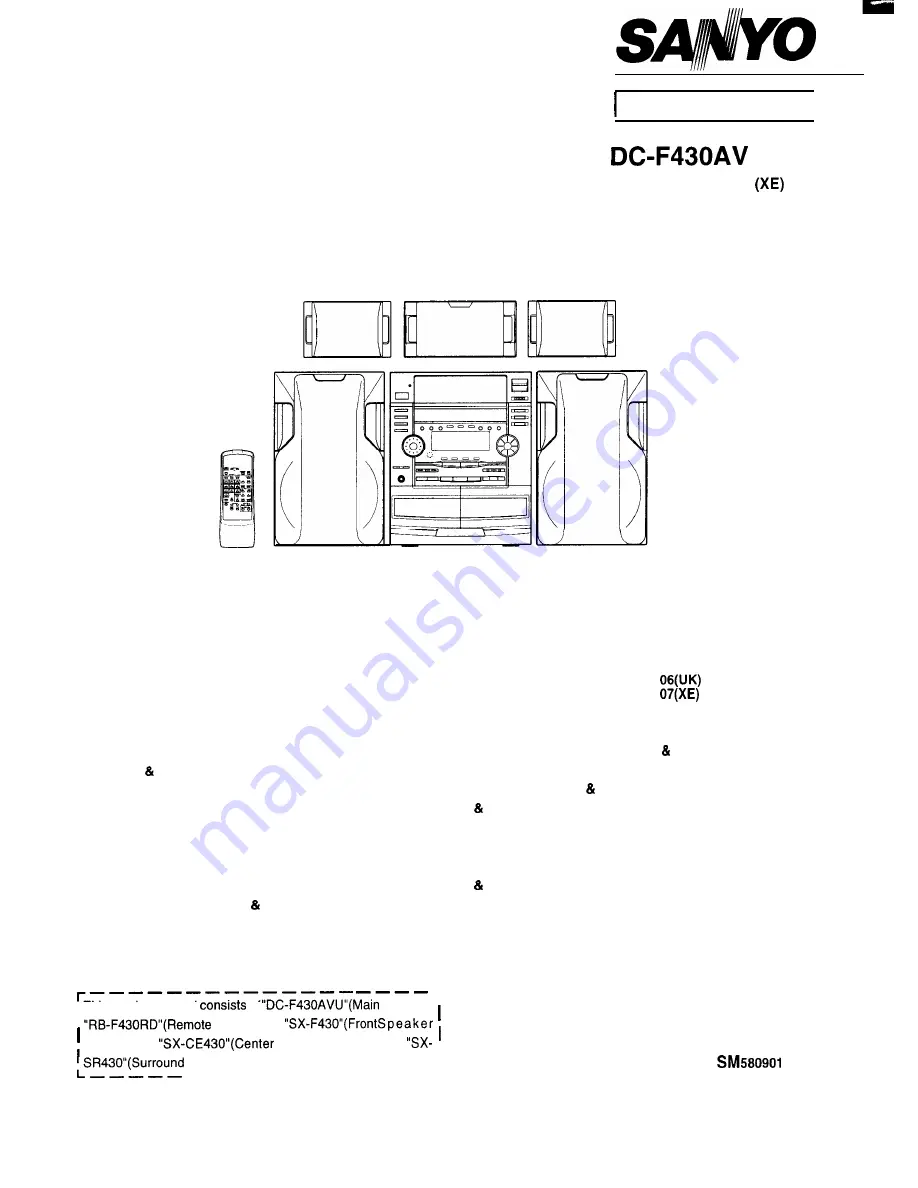

Mini Component System

(UK)

CONTENTS

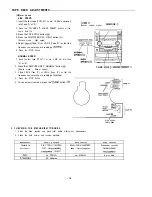

SPECIFICATION ...................................................................... 1

WHAT TO DO IF.. ..................................................................... 1

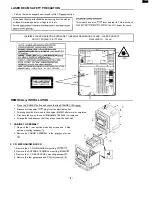

LASER BEAM SAFETY PRECAUTIONS ................................ 2

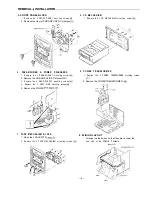

REMOVAL

INSTALLATION ................................................. 2

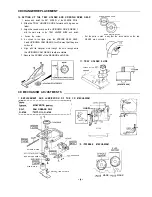

TUNER ADJUSTMENT ............................................................ 4

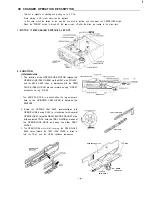

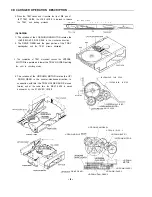

C D CHANGER OPERATION DESCRIPTION .......................... 5

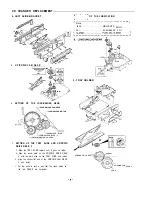

CDCHANGERREPLACEMENT

............................................. 7

CD MECHANISM ADJUSTMENT ............................................ 9

CD PLAYER ADJUSTMENTS ............................................... 11

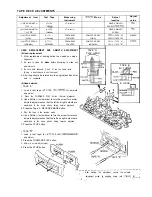

TAPE DECK ADJUSTMENTS ............................................... 13

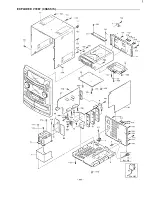

EXPLODED VIEW (CABINET

CHASSIS) .......................... 15

I

This service manual

of

unit),

1

control) and

system) and

Speaker system) and

Speaker system).

I

- - - - - - - - - - - - - - - - -

- -l

PRODUCT CODE No.

129 530

129 530

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

EXPLODED VIEW (TAPE MECHANISM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

EXPLODED VIEW (CD CHANGER BASE MECHANISM). 27

EXPLODED VIEW (CD CHANGER MECHANISM) . . . . . . . . . . . . . . . 28

IC BLOCK DIAGRAM DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

IC

TRANSISTOR VOLTAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

WIRING CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

IC

TRANSISTOR VOLTAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

REFERENCE No.

Summary of Contents for DC-F430AV

Page 16: ...EXPLODED VIEW CHASSIS I YOi 4 YO4 YOI d k 0 q f Y02 9 a L YO2 i y i A _ _ I ...

Page 17: ...EXPLODED VIEW CABINET U II G J I L Ei 16 ...

Page 29: ...EXPL ODED VIEW CD CHANGER MECHANISM PARTl 28 ...

Page 44: ... i I I ...

Page 51: ...1 I V P a CN421 C N 4 2 2 TO FRONT C N 4 2 4 TO AMP TO DECK 50 ...

Page 54: ...WIRING DIAGRAM CD ...

Page 56: ...WIRING DIAGRAM DECK 55 ...

Page 57: ... 56 ...

Page 58: ...WIRING DIAGRAM FRONT ...

Page 59: ...r e I 58 ...

Page 60: ...WIRING DIAGRAM POWER CENTER SURROUND SPEAKERS FRONT SPEAKERS SUB Ob OFE I 59 ...

Page 61: ...i I 60 ...

Page 62: ...WIRING DIAGRAM PRE AMP TUNER 61 ...

Page 63: ... 62 ...

Page 66: ...Apr 98 2300 NS Printed in Japan SANYO Electric Co Ltd Osaka Japan ...