26

ROUTINE MAINTENANCE

WARNING

Always disconnect the power supply to the unit prior to any repair or maintenance

of the unit in

order to prevent electric shock or injury.

Ensure you do not inhale or consume medication or aerosols

from around the unit at the time of

maintenance. These may be harmful to your health.

Cleaning of cabinet

• Clean the unit once a month. Regular cleaning keeps the unit looking new.

• Use a dry cloth to wipe off small amounts of dirt on the outside and inside of the unit and all accessories.

If the outside panels are dirty, clean them with a diluted neutral dishwashing detergent. (Undiluted

detergent can damage the plastic components. For the dilution, refer to the instruction of the detergent.)

After the cleaning with the diluted detergent, always wipe it off with a wet cloth. Then wipe off the

cabinet or accessories with a dry cloth.

• Never pour water onto or into the unit. Doing so can damage the electric insulation and cause failure.

• The compressor and other mechanical parts are completely sealed. This unit requires absolutely no

lubrication.

• Check the back-up system by pressing TEST switch once a month if it is installed.

• Remove the frost or ice on the chamber wall and clean the condenser filter once a month.

Cleaning of condenser filter

This unit is provided with the filter check lamp on the control panel. Clean the filter when this lamp lights.

Clean the filter once a month even if the check lamp is not on since a clogged filter may cause shorter

compressor life as well as the poor cooling.

Clean the filter by the procedure below.

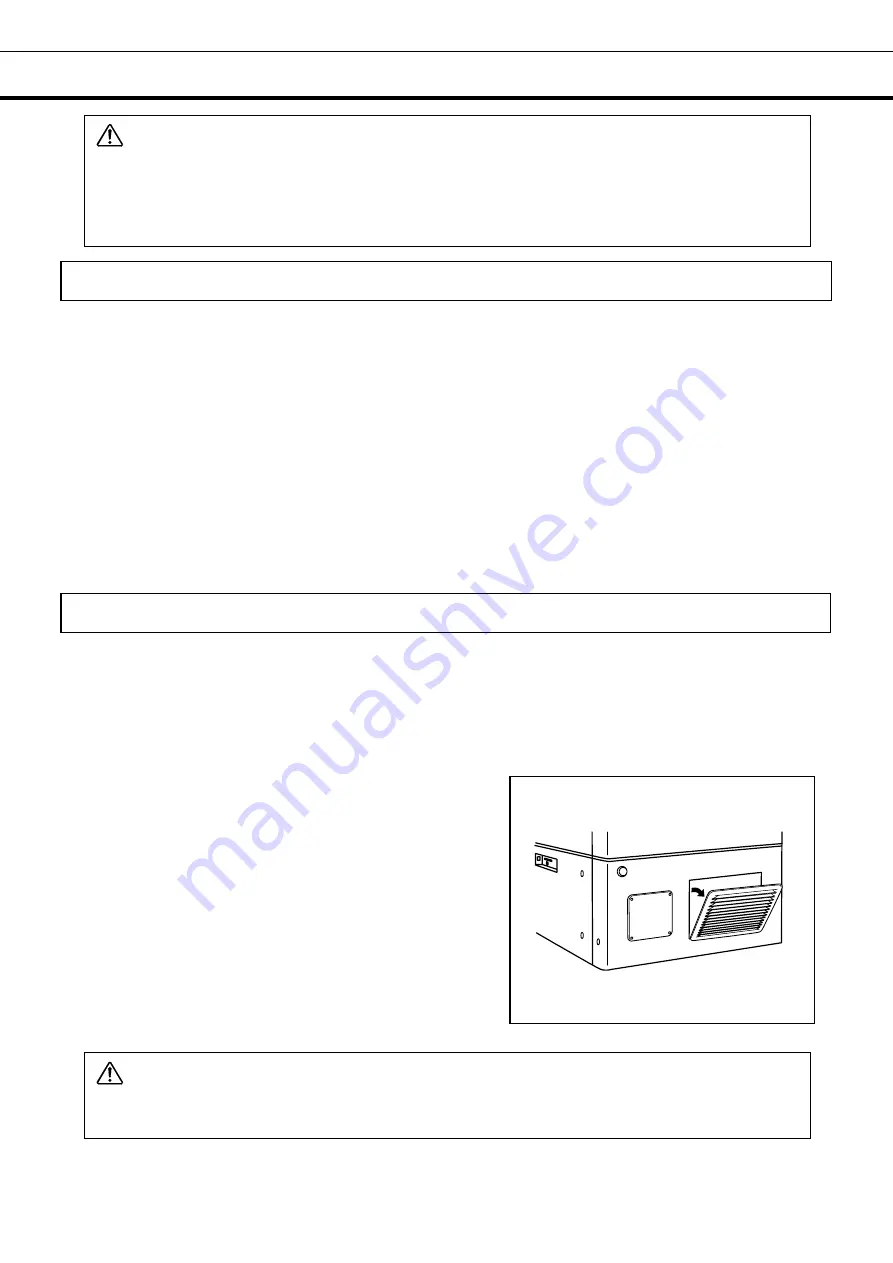

1.

Open the grille by pulling it to you as shown in the

figure.

2.

Take out the condenser filter.

3.

Wash the filter with water.

4.

Replace the filter and the grille.

5.

Check that the filter check lamp is off in the event the

check lamp was ON.

WARNING

Do not touch the condenser directly

when the filter is removed for cleaning.

This may cause injury by

hot surface.