- 7 -

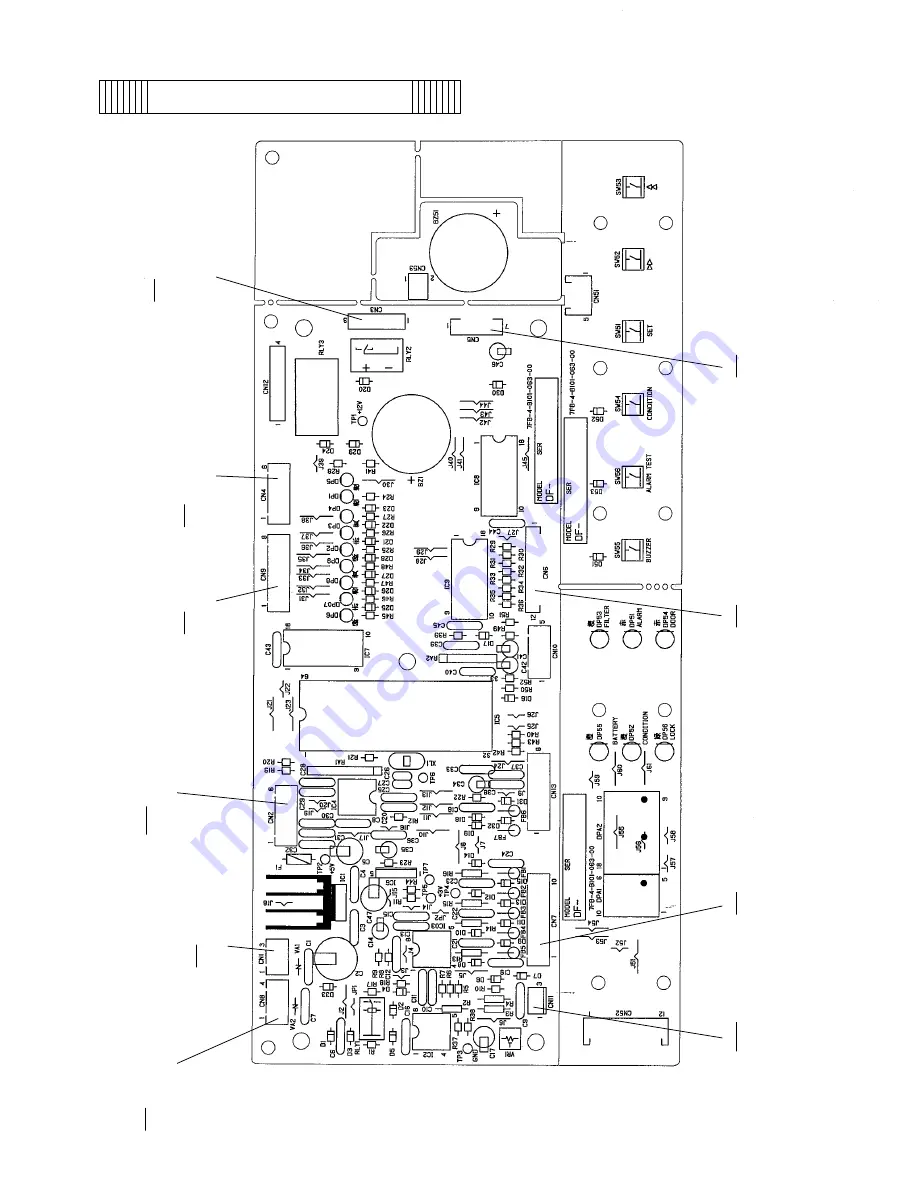

CN8

#1-#2 Battery

, Battery switch

#3-#4 Power transformer

CN1

#1-#3

Switching power supply

CN2

MTR-480 (option)

MTR-L03 (option)

CN9

#1-#2

H comp relay

CN4

#1-#2 T

emp.control relay

#3-#4 Heater relay

CN3

Remote alarm terminal

#1 COM

#2 N.O

.

#3 N.C.

CN11

#1-#3

Temp.sensor

CN7

#1-#2 Door switch

#5-#6 A

T sensor

#7-#8 Filter sensor

#9-#10 Cascade sensor

CN6

Display PCB

CN5

#1-#5 Switch PCB

#6-#7 Buzzer PCB

Components on PCB

Summary of Contents for MDF-U55V

Page 14: ...Wiring diagram 11 ...

Page 15: ...Circuit diagram 12 ...