PLC-WXU10

41

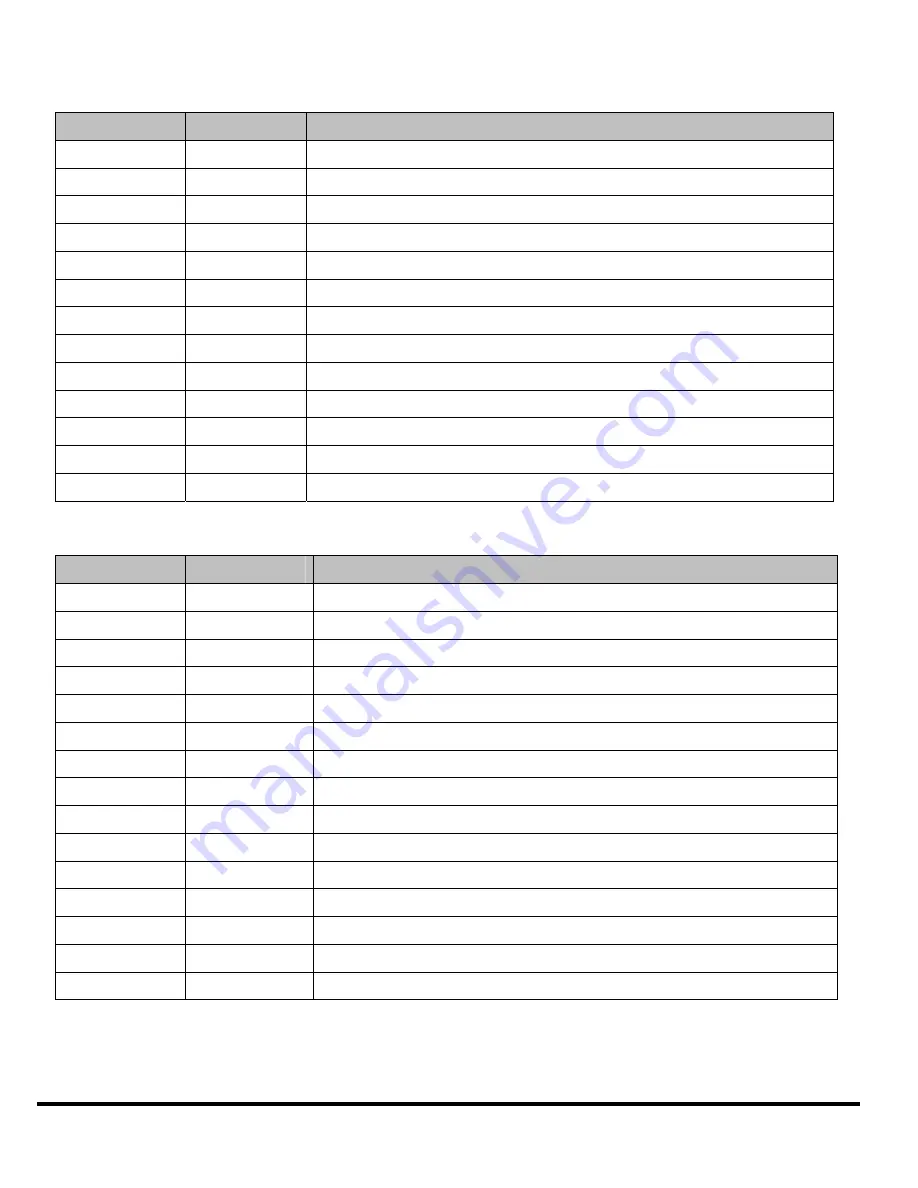

6.3 Accessory

Key No.

P/N

Description

645 096 2004

REMOTE CONTROL

645 096 8907

WY BAG

645 096 8952

OWNERS MANUAL(JAPAN)

645 096 8969

OWNERS MANUAL(US/EU/UK)

645 096 8983

QUICK SETUP GUIDE

645 096 8976

OWNERS MANUAL(CHN)

AC CORD

645 096 8693

POWER CORD(JAPAN)

AC CORD

645 096 8709

POWER CORD(CHINA)

AC CORD

645 096 8716

POWER CORD(EUROPE)

AC CORD

645 096 8730

POWER CORD(UK)

AC CORD

645 096 8723

POWER CORD(USA)

CABLE

645 096 8938

S-VIDEO CABLE

CABLE

645 096 8945

D-SUB 15P CABLE

6.4 MISCELLANEOUS/Module

Key No.

P/N

Description

M01

645 096 2011

KEYPAD PCB

M02

645 096 2028

MB(NO WIRE)

M03

645 096 2035

BALLAST MODULE(380V)

M04

645 096 2042

PWR(NO WIRE)

M05

645 096 2059

HIKARI SAKU

M06

645 096 2646

KEY-BUTTON

M07

645 096 2073

FRONT IR PCB&BACK IR PCB

M08

645 096 2080

WINDTUNNEL CUBE PAD

M09

645 096 2097

REAR RUBBER

M10

6450 96 2103

LENS CAP

M11

645 096 2110

CUBE BLOWER MODULE

M12

645 096 2127

FRONT COVER METAL

M13

645 096 2134

FOOT AND COVER

M14

645 096 2141

THERMAL PCB

M15

645 096 2158

KEY NAME PLATE

Summary of Contents for PLC-WXU10B

Page 7: ...PLC WXU10 4 1 3 PLC WXU10 System Block Diagram ...

Page 17: ...PLC WXU10 14 Step Figure Description 9 Remove the screws as shown 10 Remove the housing mylar ...

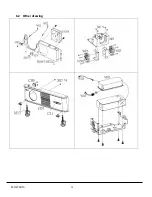

Page 40: ...PLC WXU10 37 6 1 Mechanical Drawing M15 mylar 2 M12 ...

Page 41: ...PLC WXU10 38 6 2 Other drawing ...

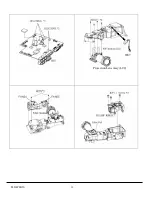

Page 42: ...PLC WXU10 39 Projection Lens Assy L02 W07 ...

Page 43: ...PLC WXU10 40 W08 is the UV lens which is used to detect the temperature of panel W08 ...

Page 51: ......

Page 52: ... KJ3A Jan 2008 DC 300 Printed in Japan SANYO Electric Co Ltd ...