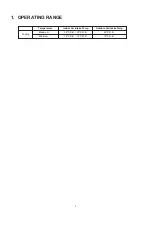

2. SPECIFICATIONS

2-1. Unit Specifications

DATA SUBJECT TO CHANGE WITHOUT NOTICE.

Remarks: Rating conditions are:

Indoor air temperature 27°C D.B. / 19°C W.B.

Outdoor air temperature 35°C D.B. / 24°C W.B.

No. of indoor units.

1-unit

2-units

Power Source

240 V Single phase 50 Hz

Cooling

Capacity

kW

2.50

5.00

BTU/h

8,500

17,100

Air circulation (High)

m3/h

430

430

×

2

Moisture removal (High)

Liters/h

0.80

0.80

×

2

Voltage rating

V

240

Available voltage range

V

216 to 264

Running amperes

A

5.0

9.3

Power input

W

1,110

2,120

Power factor

%

93

95

C.O.P.

W/W

2.3

2.4

Compressor locked rotor amperes

A

24

48

Controls / Temperature control

Microprocessor / I.C. thermostat

Control unit

Wireless remote control unit

Timer

1-hour OFF / 12-hour ON or OFF

Fan speeds

Indoor / Outdoor

3 and Auto / 1 (Hi)

Airflow direction (Indoor)

Horizontal

Manual

Vertical

Auto

Air filter

Washable, Anti – Mold

Compressor

Rotary (Hermetic)

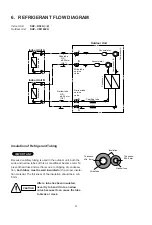

Refrigerant / Amount charged at shipment

g

R22 / 1,260 (630

✕

2)

Refrigerant control

Capillary tube

Operation sound

Indoor – Hi / Me / Lo

dB-A

39 / 37 / 33

Outdoor – Hi

dB-A

53

Refrigerant tubing connections

Flare type

Max. allowable tubing length at shipment

m

7.5

Refrigerant tube

Narrow tube

mm (in.)

6.35 (1/4)

diameter

Wide tube

mm (in.)

9.52 (3/8)

Refrigerant tube kit / Accessories

Optional / Hanging wall bracket

Indoor Unit

Outdoor Unit

Unit dimensions

Height

mm

250

630

Width

mm

790

810

Depth

mm

174

275

Package dimensions

Height

mm

242

704

Width

mm

850

953

Depth

mm

312

369

Weight

Net

kg

7.0

48.0

Shipping

kg

10.0

52.5

Shipping volume

m3

0.06

0.25

Dimensions & Weight

Features

Electrical Rating

Performance

Indoor Unit

SAP – K92A

Outdoor Unit

SAP – CM1822A

2