35

10-5. In Case of Compressor Malfunction

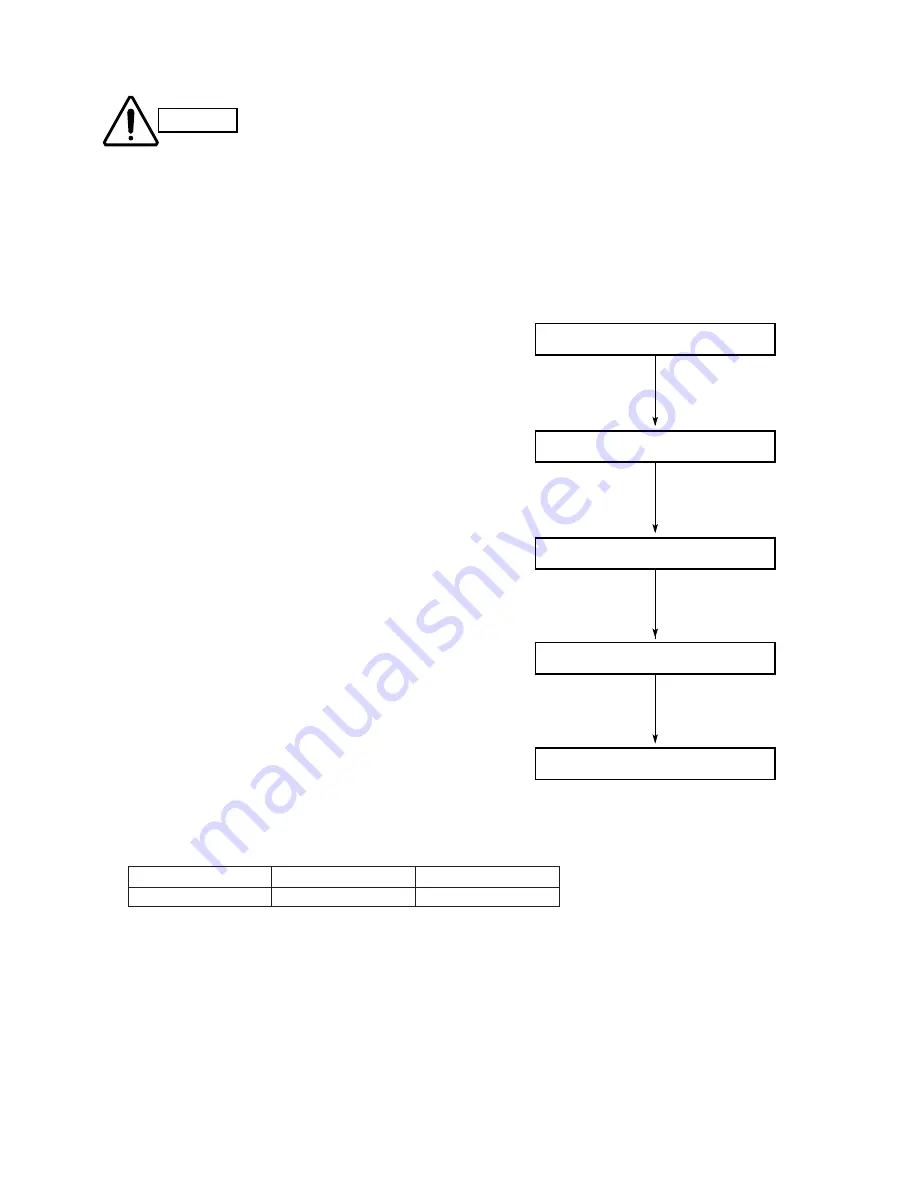

10-5-1. Procedure for replacing compressor

(1) Recovering refrigerant

●

Any remaining refrigerant inside the unit should not be

released to the atmosphere, but recovered using the

refrigerant recovery unit for R410A.

●

Do not reuse the recovered refrigerant, since it will

contain impurities.

(2) Replacing Compressor

●

Soon after removing seals of both discharge and

suction tubes of the new compressor, replace it

quickly.

(3) Checking for sealing

●

Use nitrogen gas for the pressurized gas, and never

use a refrigerant other than R410A. Also do not use

oxygen or any flammable gas.

(4) Evacuation

●

Use a solenoid valve-installed vacuum pump so

that even if power is cut off in the middle of evacuation

of air due to a power interruption, the valve will

prevent the pump oil from flowing back.

●

The equipment may be damaged if moisture remains

in the tubing, thus carry out the evacuation thoroughly.

●

When using a vacuum pump with exhaust air volume

more than 25L/min. and ultimate vacuum pressure

rate of 0.05Torr:

Standard time for evacuation

CAUTION

●

Should the compressor malfunction, be sure to make the switch to a replacement

compressor as quickly as possible.

●

Use only the tools indicated exclusively for R410A.

➞

See “10-3. Tools

Specifically for R410A.”

(1) Recover refrigerant

OK

(2) Replace compressor

OK

(3) Check for sealing

OK

(4) Evacuation

OK

(5) Recharge

Length of tubing

Less than 10 meters

More than 10 meters

Time

More than 10 minutes

More than 15 minutes