-

2

-

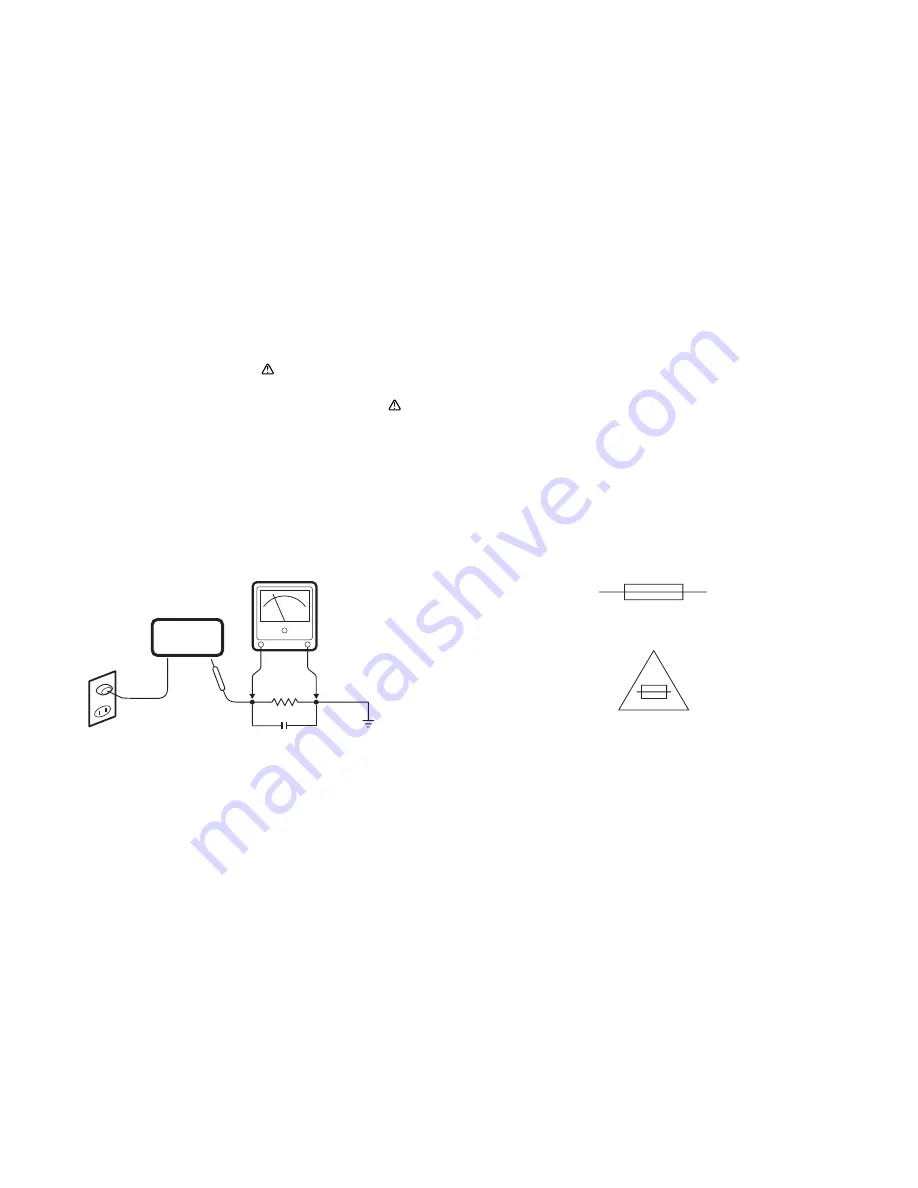

AC VOLTMETER

(5000 ohms per volt or more sensitivity)

Reading should not exceed 300 mVrms

1500 Ohm

10 Watt

0.15uF 150 VAC

Place this probe on each

exposed metallic part

Good earth ground such as

a water pipe,conduit etc.

Voltmeter Hook-up for Leakage Current Check

AC OUTLET

SAFETY PRECAUTIONS

WARNING:

Service should not be attempted by anyone unfamiliar with the necessary precautions for this recording or playback

equipment. The following precautions are necessary during servicing:

1.

Many electrical and mechanical parts in this recorder have

special safety-related characteristics for providing protec-

tion against shock, fire and other hazards. These charac-

teristics often go unnoticed in a visual inspection, and the

protection afforded by them cannot necessarily be ob-

tained by using replacement components with higher

ratings (voltage, wattage, etc.).

2.

Replacement parts having special safety-related charac-

teristics are identified in this manual, and in the schematic

diagrams, by the symbol

. These components have

values that are of special significance to product safety.

Should any component (identified by the symbol

) need

to be replaced, use only the part designated in the parts

List. Do not deviate from the specified resistance, wattage,

and voltage ratings.

3.

Before returning the set to the customer, always perform

an AC leakage current check on the exposed metallic parts

of the cabinet, such as terminals, screwheads, metal

overlays, etc. to be sure that the set is safe to operate

without the danger of electrical shock, Plug the AC line

cord directly into a 120 V AC outlet. (Do not use a line

isolation transformer during this check.) Use an AC voltmeter

with a sensitivity of 5000 ohms per volt (or more) as follows:

Connect a 1500 ohms, 10 watt resistor, paralleled by a 0.15

mfd, 150 VAC capacitor, between a known good earth

ground (water pipe, conduit, etc.) and the exposed metallic

parts, one at a time. Measure the AC voltage across the

1500 ohms resistor and 0.15 mfd capacitor combination.

Reverse the AC plug at the AC outlet and repeat the AC

voltage measurements for each exposed metallic part.

The measured voltage must not exceed 300 mVrms. This

corresponds to 200 µA AC. Any value exceeding this limit

constitutes a potential shock hazard and must be corrected

immediately.

4.

Fuse symbol marks.

For CANADA

UNDERWRITERS LABORATORIES Standard

CAUTION

"Risk of fire-replace fuse as marked"

For U.S.A.

Fuse rating is marked at

adjacent fuse.

Color LCD

monitor