Page 4 of 8

G03711095

11-4-14

Use a level to plumb both wall jambs [

B

], then mark

the pre-drilled hole locations on the wall. Lightly mark

both sides of the tub track [

A

] with a pencil, and then

remove all the parts.

For tile or marble walls, drill six 7/32” diameter holes and

insert the plastic wall anchors [

C

]. A center punch helps

locate the holes accurately.

Attachments to fiberglass or acrylic units can be made in

2 ways. If reinforcement is built into the wall of the unit,

drill six 1/8” diameter holes and install the screws directly

into the reinforcement. If the walls are not reinforced, drill

six 7/32” diameter holes and insert the plastic wall an-

chors or molly bolts (molly bolts not supplied by Alumax).

CAUTION:

The tub track should never be screwed to

the tub. This will damage the tub and cause leakage.

1

2

Measure the wall-to-wall opening along the center

of the tub rim. Cut the tub track [

A

] 1/16” short of this

dimension. An inexpensive miter box available at your

local hardware store will help you get clean square cuts.

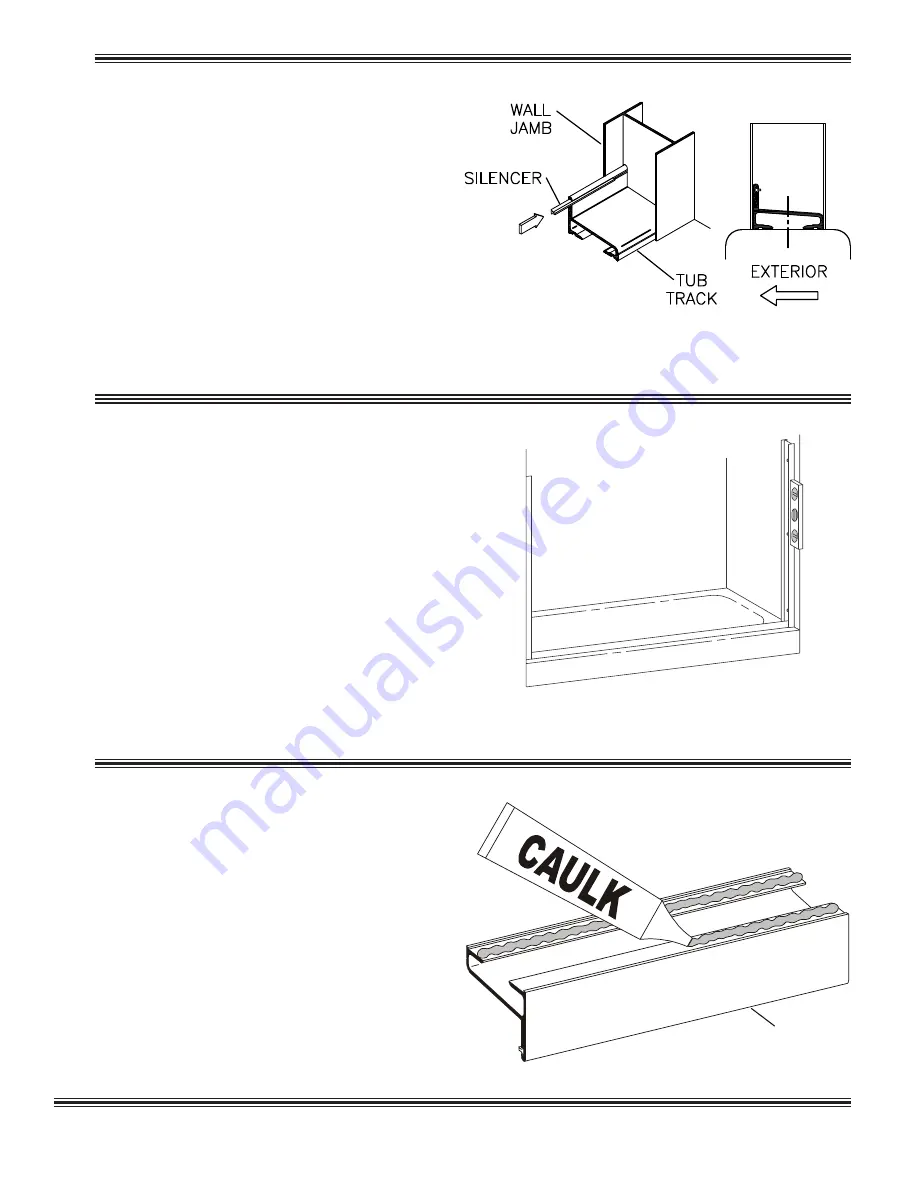

If the vinyl silencer [

V

] is separate from the tub track [

A

]

slide the silencer into the slot in the tub track and trim

to the same length.

Position the tub track in the center of the tub rim with

the tall leg to the exterior. It may be necessary to file

a radius on the ends of the tub track and wall jambs to

match the corners of the tub.

Press both wall jambs [

B

] into position over the tub track.

Masking tape can be used to hold all the parts in place

temporarily.

3

Before replacing the tub track [

A

], force a slight

downward bow in the extrusion. This will ensure the

track fits tight to the sill. Run a bead of caulk on both flat

surfaces on the bottom of the tub track. Then replace

the track on the bath sill in the exact position marked in

Step #

2

and with the tall leg to the exterior of the bath.

Seat the tub track firmly.

NOTE:

Improper caulking will result in leaks.

TUB

TRACK