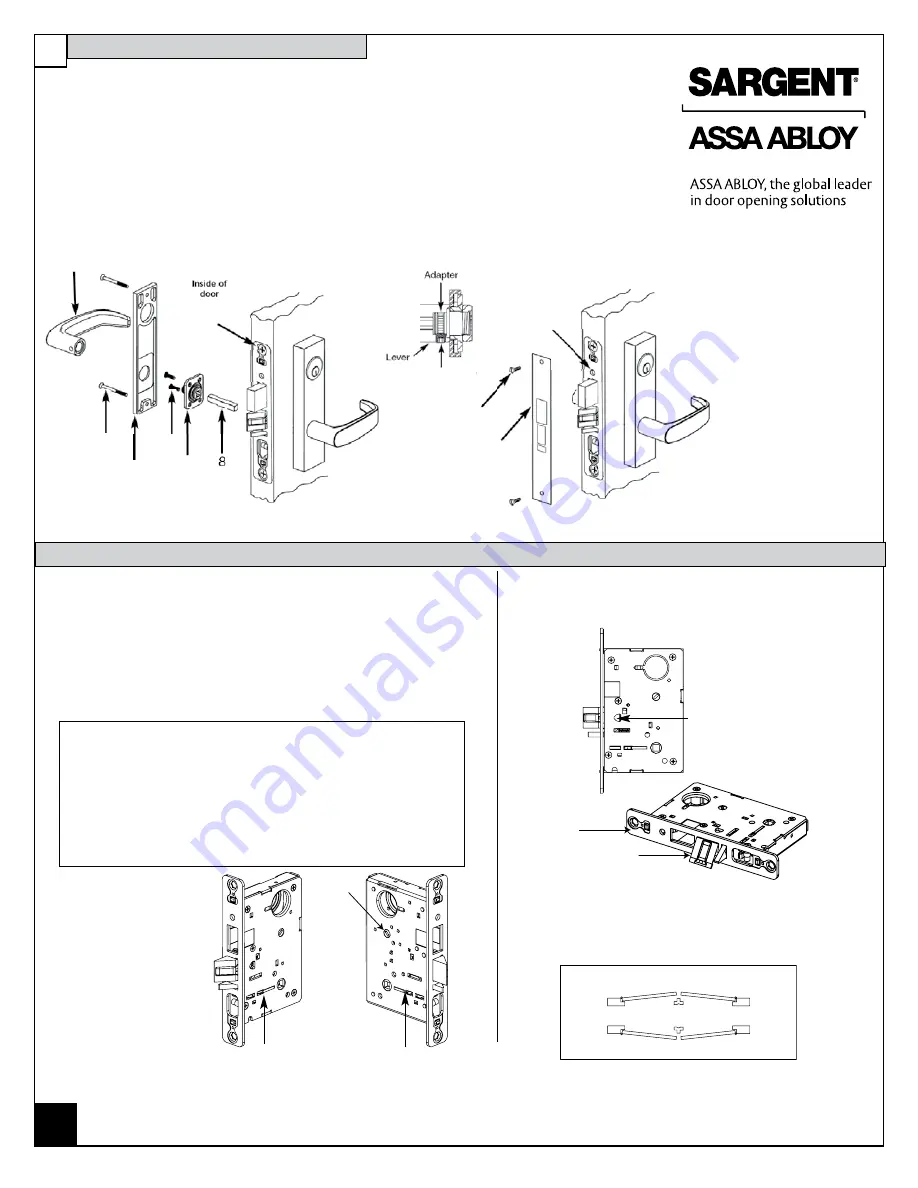

Inside Adapter & Plate Assembly

A7334G

2

3

A. Slide spindle (8) into lockbody hub

B. Slide adapter & plate assembly (7) over

spindle and secure with two #8-32 screws (6)

(do not tighten)

C. Tighten lockbody screws (13) on edge of

the door

D. Tighten both #8-32 (6) screws, securing

adapter & plate assembly

E. Position inside Escutcheon (5) and secure

with two 1/4-20 x 1-3/4" screws (4)

F. Place inside lever (1) horizontally onto lever

spindle (8). Hold lever firmly against the

escutcheon.

G. Use the 1/8" Allen wrench to tighten the set

screw (3) securely. Set screw should seat in

the groove of the inside adapter (7).

H. Pull on lever to verify set screw is seated

properly.

Copyright© 2005, 2008, 2010, 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

INSIDE

INSIDE

OUTSIDE

OUTSIDE

LEFT HAND

LEFT HAND

REVERSE

BEVEL

RIGHT HAND

RIGHT HAND

REVERSE

BEVEL

DOOR HANDS DETERMINED FROM OUTSIDE

DOOR HANDING

Red color indicates locked

side of door

Locking piece

slot

Lock

front

Latch

Hub

Note: Red surface of locking piece must face secure side of door.

To rotate locking piece:

1.Position lockbody with red surface of locking piece visible

2. Insert blade type screwdriver into locking piece slot to rotate

locking piece

3. Push locking piece toward back of lock body and rotate 180°

until RED surface shows on opposite side

Note: Beveled surface of latch must face strike. The

deadlatch is self adjusting. To change hand of latch:

1. Insert screwdriver blade

into the spade shaped

slot

2. Rotate screwdriver 90º to push latchbolt out of the lock

case, until back of latchbolt clears lock front. Then

rotate latchbolt 180º allowing it re-enter the lockbody.

(Note: Latch can not be unscrewed)

How to Change Hand of Lock

Note: Functions 04, 06, 13, 17 and 31 require the following,

before the locking piece can be rotated:

(a) Remove the Green catch screw

(b) Rotate hub to make straight

(c) Rotate locking piece for required hand

(d) Red surface faces locked side of door

(e) Rotate hub to the original 45 degree position as shown

on lock case

(f) Reinstall the Green catch screw

7

4

6

13

4

5

Cylinder retainer

access hole

12

11

3

1

I. With the cylinder flush to the

escutcheon face, rotate cylinder

to make the keyway vertical. This

ensures that the cylinder retainer

fork will line up with the notch on

the side of the cylinder.

J. Secure the cylinder with a #2

Phillips screw driver, using the

cylinder retainer access hole.

K. Test key & cylinder to verify the

lock is functioning correctly.

L. Secure Outside Front (12)

with two #8-32 screws (11) to

the lockbody.