Summary of Contents for Combics CAH3

Page 130: ...130 Operating Instructions Combics Complete Scales Declarations of Conformity ...

Page 131: ...Operating Instructions Combics Complete Scales 131 Declarations of Conformity ...

Page 132: ...132 Operating Instructions Combics Complete Scales Test Certificate ...

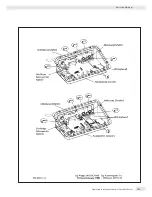

Page 133: ...Operating Instructions Combics Complete Scales 133 Plates and Markings ...

Page 134: ...134 Operating Instructions Combics Complete Scales Plates and Markings ...

Page 135: ...Operating Instructions Combics Complete Scales 135 Plates and Markings ...

Page 136: ...136 Operating Instructions Combics Complete Scales Plates and Markings ...

Page 139: ...Operating Instructions Combics Complete Scales 139 ...

Page 144: ......

Page 146: ......

Page 147: ......