SARTORIUS PMA 7500...

7

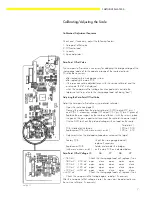

Calibrating/Adjusting the Scale

Calibration/Adjustment Sequence

Check and, if necessary, adjust the following factors:

1. Zero-point offset value

2. Off-center load

3. Linearity

4. Span adjustment

Zero-Point Offset Value

The zero-point offset value is necessary for adapting the bridge voltage of the

strain-gauge load cell to the operating range of the scale electronics.

This may be necessary:

– after replacing the strain-gauge system

– after replacing the main PCB

– if the span cannot be adjusted (even with the service software) and the

error code “

E 02

” is displayed

– when the zero-point offset voltage has changed and is outside the

tolerance limit (e.g., due to the strain-gauge load cell being “bent”)

Adjusting the Zero-Point Offset Value

Adjust the zero-point offset value using a digital voltmeter.

– Open the scale (see page9)

– Connect the cable from the digital voltmeter (DVM) to plug ST2, pins 1

and 2 (Pin 1: measuring voltage (OP output IC6 / pin 6), pin 2: ground)

– Replace the pan support on the scale and fasten it with the screws, place

the pan on the pan support and re-connect the scale to the power supply

– Use the DVM to check the preload voltage with no load on the scale:

Target (mV)

PCB installed at the factory

-120 to -1,600

Replacement PCB (with menu access switch):

-120 to -350

– Adjustment when the preload voltage does not equal the target:

Factory PCB:

Check the strain-gauge load cell;

replace if necessary

Replacement PCB

Solder or de-solder the bridges

(with menu access switch): on the main PCB as indicated below

Zero-Point Offset Voltage J5

J6

J7

J8

J9

< -580 mV

Check the strain-gauge load cell; replace if nec.

-580 mV ... -350 mV

open

close

open

open

open

-350 mV ... -100 mV

open

open

open

open

close

-100 mV ...+120 mV

open

open

open

close

open

+120 mV ...+360 mV

open

open

close

open

close

> +360 mV

Check the strain-gauge load cell; replace if nec.

– Check the zero-point offset voltage again; re-adjust if necessary

After the zero-point offset voltage is reset, the span must be adjusted (using

the service software, if necessary).

Nullp-d.TIF

Summary of Contents for PMA7500D-X

Page 2: ......

Page 15: ...SARTORIUS PMA 7500 15...