15

SARTORIUS QC - Scales

Zero Point Offset Value

The zero point offset value must be adjusted in order to adapt the bridge

voltage of the strain gauge System to the working range of the scale’s

electronics. You may need to adjust this value:

-

after replacing the strain gauge system

-

after replacing the main PCB

-

if the scale’s span (sensitivity) cannot be adjusted (not even with the

PSION server) and the error code “Err02” is generated

-

if the zero point offset voltage has changed and lies outside the tolerance

range, e.g., if the strain gauge System becomes “warped”

Adjusting the Zero Point Offset Value

The are two ways of adjusting the zero point offset value:

1. using a digital voltmeter

2. using the PSION server, Datapack version 4.4 and newer

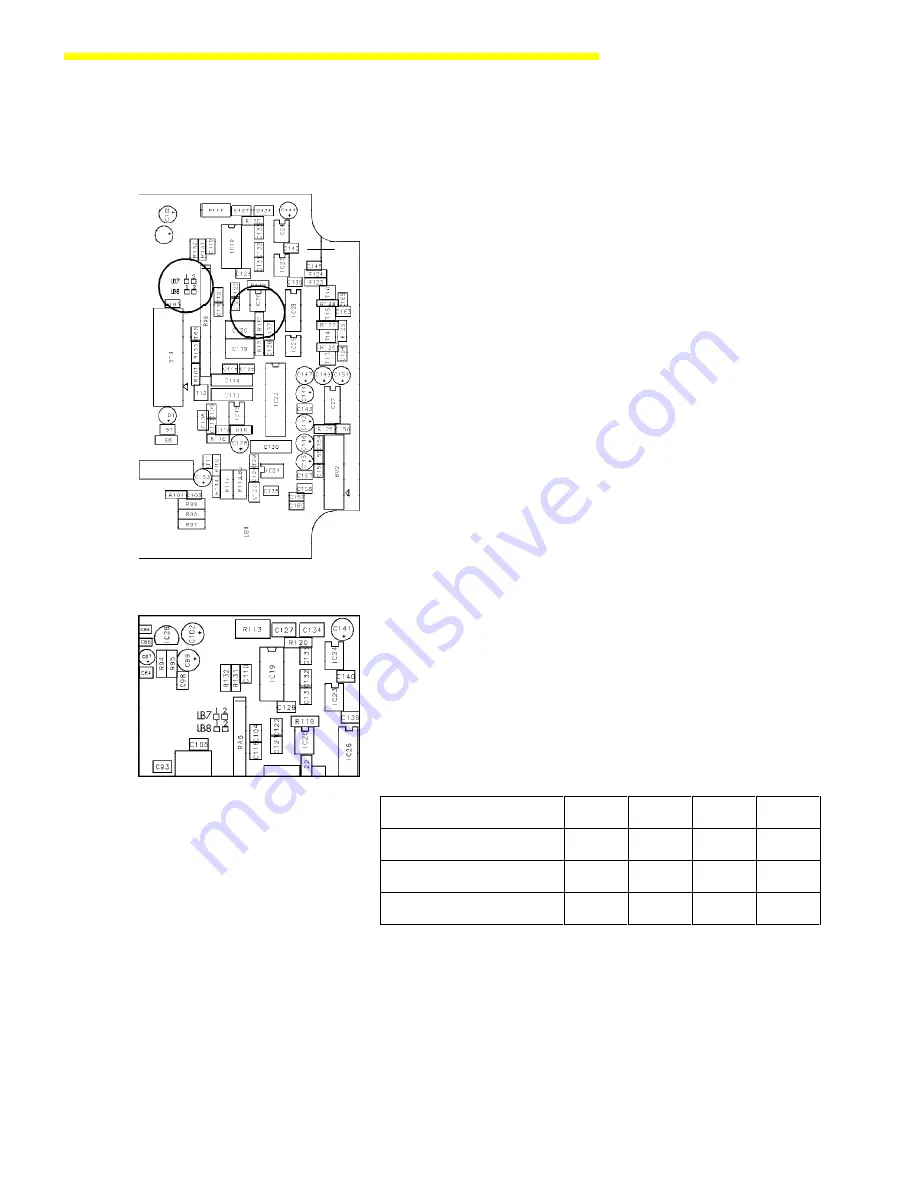

1. Adjustment using a digital voltmeter:

-

Open the display unit by removing the 4 screws at the back.

-

Reconnect the scale to AC power.

-

With no load on the weighing pan, use the digital voltmeter to measure

to ground on R122 (OP output IC 20 / pin 6).

The zero point offset voltage should be between - 300 mV and - 2V.

-

If the zero point offset voltage lies outside these limits, you can adjust it by

changing the following solder bridges on the main PCB.

Solder bridge

Position number

LB 7

[ 1 ] [ 2 ]

LB 8

[ 1 ] [ 2 ]

LB7

LB7/LB8

LB8

LB7/LB8

Zero Point Offset Voltage

1 / 2

1 / 1

1 / 2

2 / 2

< - 2 V

open

close

open

open

> - 300 mV

close

open

close

open

Summary of Contents for QC34EDE-S

Page 2: ...2...