59

Service Manual Signum

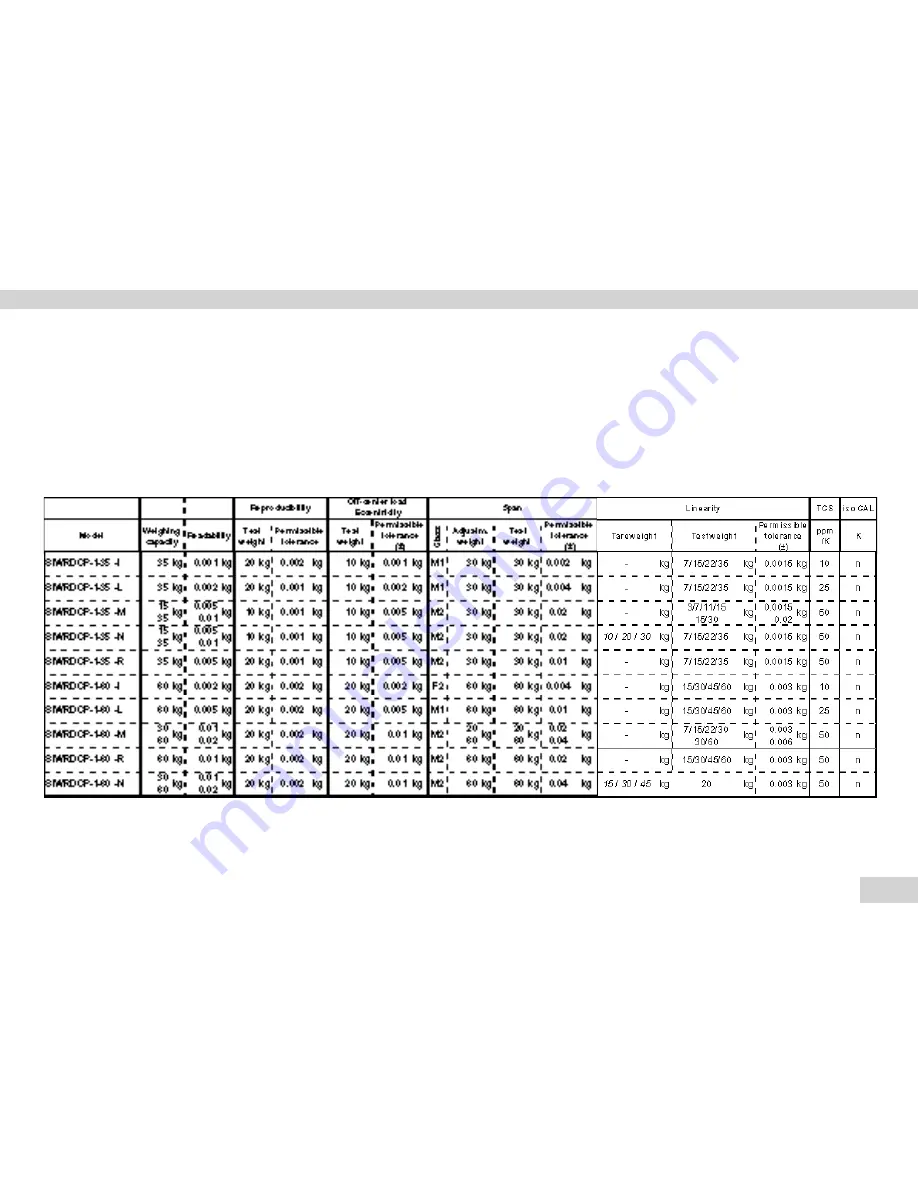

Calibration/Adjustment Data

Calibration/Adjustment Data for the SIWR

Example for the order number of a Signum full range scale:

SIWRDCP-2-60-R oder SIWRDCP-3-60-RCE

Model type | Sensor | Platform | Type of/ | Application- |

Capacity |

Display | Verifiable/ |

technology

dimensions

material

level

(kg)

resolution

verified

(in mm)

versions

SIW

R

1)

DC

P

4)

2

15

R

RCE

1)

= SIWR: „Regular“ standard weighing system - (strain gauge technology)

4)

= Painted

just_Signum_290508.xls