33

SAS 1SF - Twin Screw Feeder Assy & Control - APRIL 2020

TECHNICAL SPECIFICATIONS

The D series screw feeders are equipped with a double extracting screw, they guarantee

a homogeneous material flow, high precision and dosing regularity thanks also to the

screws that are machine made for a perfect coupling.

The D series twin screw feeders are designed for the dosing of powdered material and

synthetic fibres. They are available both on volumetric and gravimetric version with an

electronic loading cell weighting system that guarantees high precision and reliability.

They are used in their different configurations in all industrial fields, from concrete to

chemistry, from food to pharmaceutical industry.

The different configurations make them suitable for the use of materials that have very

different granulometry and fluency.

They are available also in configuration for ATEX areas.

A screw feeder makes the function to unload a theoretically constant material quantity on

each turn. This behaviour allows to make a specific load both on the granulometric and

volumetric version. It is expressed in dm³/h and the value is determined by the following

factors:

- Dosing screw rotating speed.

- Dosing screw pitch and diameter length.

- Used product specific weight.

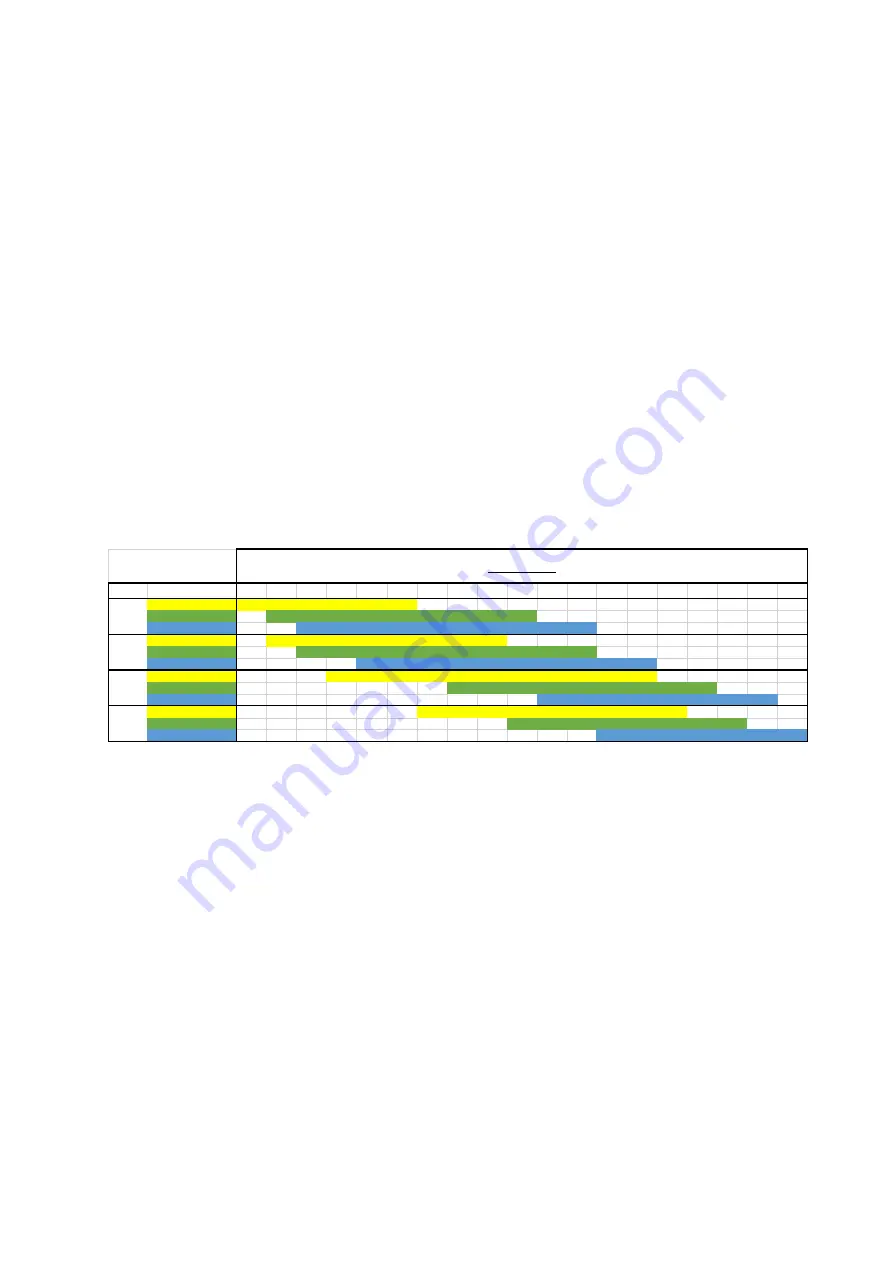

Please Note

The above table is for reference only and provides an approximate indication of Powder

Throughputs. Please contact SAS directly with details of your powder materials.

Ratio

Screw Sets

2

4

8

10

12

14

16

20

23

28

40

44

48

70

92

140

172

225

280

EX Single Pitch

EX Double Pitch

MC

EX Single Pitch

EX Double Pitch

MC

EX Single Pitch

EX Double Pitch

MC

EX Single Pitch

EX Double Pitch

MC

21:1

14:1

SAS 1SF

Twin Screw Feeder

100:1

Litres/Hour

60:1