27

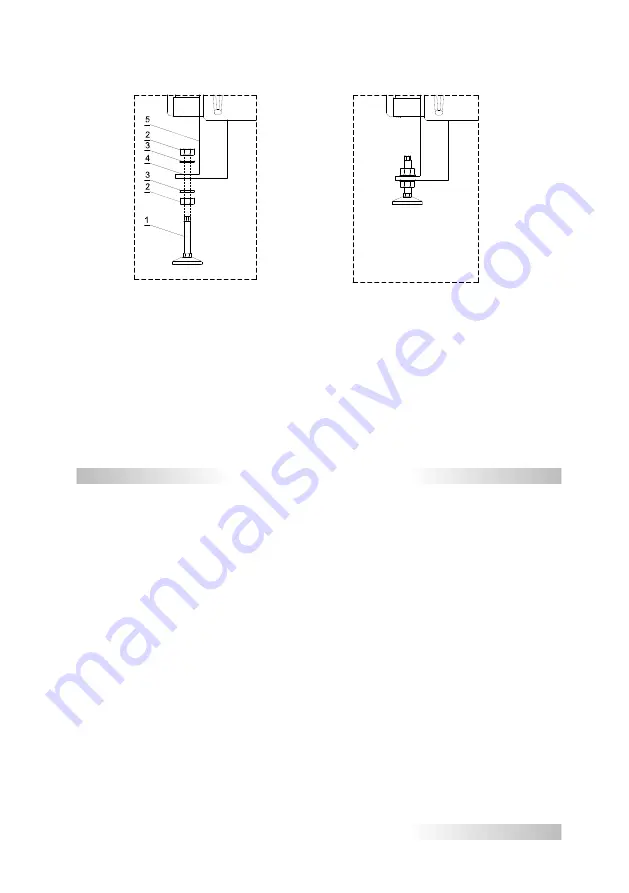

A) the fitting of adjustment feet

1 – adjustment foot with thread

(adjustment range 30 mm)

2 – nut M12

3 – washer

Ø

13

4 – installation opening

Ø

13 mm

5 – side skid of the boiler

B) boiler with feet

5.3. Pod

łą

czenie kot

ł

a do komina

10)

(np. Rozporz

ą

dzenie Ministra Infrastruktury z dnia 12.04.2002 Dz.U.Nr 75

poz.690 w sprawie warunków technicznych, jakim powinny odpowiada

ć

budynki i ich

usytuowanie).

The boiler alignment versus the floor is adjusted with a wrench No. 19 and

a bottom setting nut (item 2). When the boiler position versus the floor is finally

set, install the upper nut (item 3) and block the whole set by screwing on the

upper blocking nut (item 2). The wrench No. 19 is not provided with the boiler.

7.4. BOILER STACK CONNECTION

The design of a flue pipe and its connection to the boiler should conform to

the requirements of current national regulations in a country of destination (e.g.,

Minister of Infrastructure Regulation of 12 April 2002, Journal of Laws No. 75).

The boiler should be directly connected to the stack with a smoke connection

in form of a steel pipe, >3 mm thick (of a thermal resistance of >400°C) and of a

diameter allowing its tight connection to the flue outlet and inserting into the chim-

ney. The connection between the flue pipe and the stack must be tightly sealed

(e.g., with high temperature silicone, ceramic sealant, etc.). The pipe should rise

in the direction of the stack (min.5°).

Dimensioning and selection of the flue pipe and the connector should be

performed by a designer holding necessary licences, and the stack system

should be constructed by a qualified person in accordance with current spe-

cific regulations in a country of destination.

The flue pipe to which the central heating boiler will be connected must meet

requirements of current specific regulations of a country of destination (e.g., PN-

-89/B-10425 Smoke, fumes and ventilation ducts, made of bricks. Technical requ-

irements and acceptance tests; Minister of Infrastructure Regulation concerning

technical conditions that should be met by buildings and their setting, of 12 April

2002, Journal of Laws No. 75, item 690, as amended).

Figure 9

Installation of adjustment feet in a SAS BIO SOLID boilers