35

34

THERMAL PROTECTION

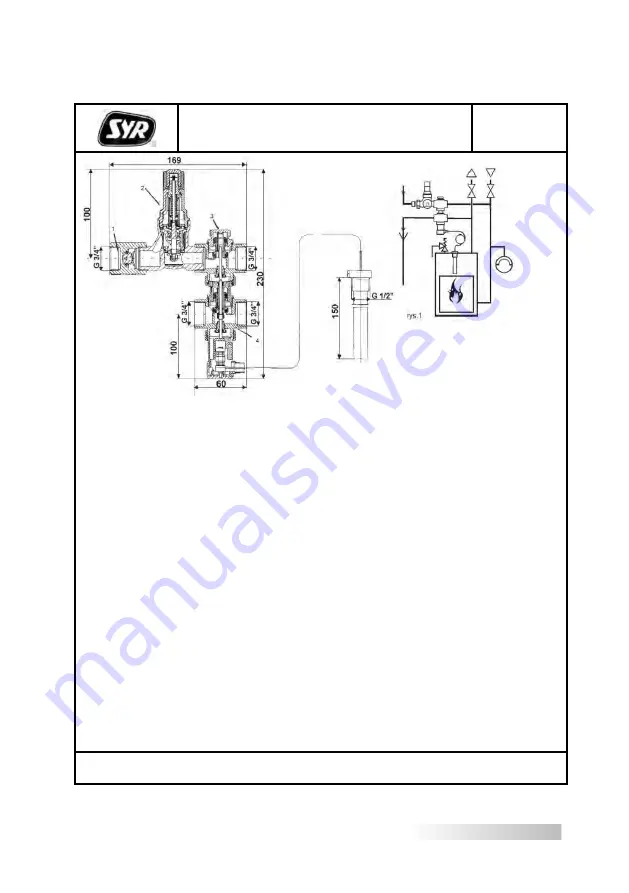

5067.

unlabeled dimensions in mm

Applications:

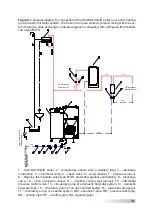

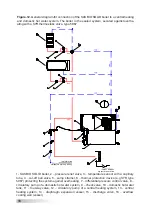

Thermal protection for 5067 installation is used to secure the solid-fuel boilers in heating installations with thermostatic valves according to Polish standard

PN-EN303-5. Highly recommended for boilers not equipped with the cooling exchanger. Figure 1 shows the installation principle, in close proximity to the

boiler, particularly paying attention to such guidance and dimensioning of pipes that ensures no pressure losses.

Assembly and operating principle:

The thermal protection valve 5067 consists of the following parts: check valve (1), pressure reducer (2), thermally

controlled filling valve (3) and discharge valve (4), temperature sensor with a capillary (5).

The reducer (2) is linked to the water network, the output of thermally controlled filling valve (3) is connected to the return pipe of the boiler. The supply

pipe to the thermally controlled discharge valve (4) with output side leading to the drain. The temperature sensor is mounted in the warmest place, preferably

at the top of the boiler. The relief valve is set permanently at 1.2 bar, hence the operating pressure to the heater unit should be higher by 0.2 – 0.3 bar.

This prevents the opening of the safety valve in the installation. It is recommended to use the safety valve set to at least 2 bar.

When the set opening temperature of approximately 90

o

C is exceeded, the fill valve begins to open (3). To maintain the stable pressure in the heating

installation, the discharge valve opens at 97

o

C. After opening the discharge valve, hot water leaves the heating installation and the cold water may flow

from the supply pipe, cooling down the boiler. When lowering the temperature of the boiler to 94

o

C the discharge valve is closed. With thermally controlled

filling valve and temperature sensor the correct pressure flow is restored in the heating installation.

When the water temperature in the boiler reaches 88

o

C, the filling valve also closes.

Execution:

Thermal safety device is controlled by the independently by other two valves: filling and discharge. The device body is moulded from brass, other parts to

come in contact with water are made of stainless steel and the plastic resistant to the temperature. All the sealing elements are made of material which is

elastic and resistant to high temperatures and wear – elastomer. The springs are made of stainless spring steel. The sensor and the capillary tube are

made of copper, additionally the bushing is nickel-plated.

The opening of the valve is controlled by the dual temperature sensor. The fittings vent by themselves. Valve components, seat and seal can be removed

and cleaned without changing settings of the opening temperature. Compact temperature sensor head may be removed for the time of assembling of the

valve body for the convenience of the user. The capillary tube from the sensor to the actuator is protected by a special metal flexible hose.

The operating pressure of the pressure reducer:

Maximum inlet water pressure:

The minimum required input water pressure:

Temperature

filling valve

discharge valve

Maximum operating temperature

Capillary tube

Weight

1.2 bar (factory locked)

16 bar

2.3 bar

Opening:

Closing:

90

°

C +0/-2

°

C

88

°

C +0/-2

°

C

97

°

C +0/-2

°

C

94

°

C +0/-2

°

C

135

°

C

1300 mm - standard length

1.5kg

HANS SASSERATH & CO. KG – HUSTY

ul.Rzepakowa 5e, 31-989 Kraków, tel. 012/645-03-04, fax 012/645-03-33, e-mail: info@husty.pl www.syr.pl