START UP:

If the motor fails to start or slows down significantly under load, shut off and disconnect from

power supply. Check that the voltage is correct for motor and the motor is turning in the proper

direction. Vane life will be drastically reduced if motor is not operating properly. Vanes can

break or be damaged it motor/pump runs in the wrong direction. Motors are equipped with

thermal protector that turns current of automatically when to mechanical or electrical overloads.

Also check the wiring instructions on motor case or on thermal plate cover.

LUBRICATION:

CAUTION: NEVER LUBRICATE DRY "OIL-LESS" AIR PUMPS.

The carbon vanes and

grease packed bearing s require NO oil.

FLUSHING:

Flushing this product to remove excessive dirt, foreign particles, moisture or oil that occurs in the

operating environment will help to maintain proper vane performance. Most pump troubles can

be corrected by flushing solvent rather than by taking apart. A noisy or inefficient pump is

frequently nothing more serious than vanes stuck in a rotor slot due to foreign material (dust)

and / or dirty filters.

CAUTION

-- Recommended commercial solvents for SAS pumps are Loctite Safety Solvent,

Inhibisol Safety Solvent, and Dow Chemical Chlorothane. In the event one of the above are not

available, use any NON-FLAMMABLE, NON-TOXIC, NON-PETROLEUM BASE, INDUSTRIAL

CLEANING SOLVENT. (SAS PUMP FLUSHING LIQUID --- P/N 9700-11).

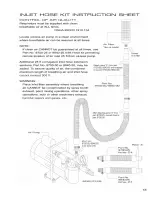

FLUSHING PROCEDURES:

Remove Intake Filter Assembly and Exhaust Port Assembly. Flushing should be done while the

unit is running and in a well ventilated area. Then while wearing proper protection have a clean

cloth over the exhaust port marked "OUT". Spray or pour a small amount of flushing solution in

the intake port marked "IN". Continue flushing until solution coming out exhaust port appears to

be clear. After all solvent has passed through the pump continue to let the pump run while

unseen solution can dissipate into the air, then re-attach the Intake Filter Assembly to the port

marked “IN” and Exhaust Port Assembly to the port marked “OUT”. Frequent flushing is

recommended to help maintain proper vane performance.

FILTER ELEMENTS:

Replace Intake and Exhaust Filter every 90 to 100 running hours.

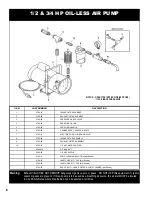

DISASSEMBLY:

If foreign matter has entered pump, try flushing. If this does not eliminate the foreign matter,

unplug pump, remove only the dead end plate and the four vanes (

DO NOT

at any time remove

the rotor). Wash vanes, end plate, and pump chamber with solvent (see above for correct type of

solvents to be used). Dry and reassemble.

DANGER:

TO PREVENT EXPLOSIVE HAZARD, DO NOT PUMP COMBUSTIBLE LIQUIDS

OR VAPORS WITH ANY SAS UNIT.

FOR MAXIMUM PUMP LIFE USE MINIMUM PRESSURE NEEDED TO DO THE JOB.

9

Summary of Contents for Opti-Fit 9800-25

Page 15: ...11...