IMPORTANT

GENERAL SAFETY INSTRUCTIONS

DO NOT

use Supplied-Air System in any atmosphere immediately Dangerous to Life or Health

(IDLH) and/or from which the worker cannot escape without the use of a respirator.

OSHA 29CFR 1910.134.

DO NOT

place oil-less air pump in an area that cannot guarantee clean, breathable air,

grade D per OSHA 29CFR 1910.134.

DO NOT

place air pump where air intake could be contaminated by spray booth exhaust, other

spraying operations (i.e. primer application, etc.), mixing operations, auto exhausts,

etc.

DO NOT

place oil-less air pump inside spray booth or in the same area in which you are

spraying.

DO NOT

use 9805-00 (1/4 & 1/3hp) or 9810-00 (1/2hp) oil-less air pump for 2-man application.

DO NOT

run oil-less air pump without breathing air-line and mask attached. This will cause

pump to over heat and shut off.

DO NOT

use 9805-00 (1/4 & 1/3hp) oil-less pump for hood-type respirator.

DO NOT

use ungrounded electrical receptacles.

DO NOT

use

ANY

electrical extension cords.

DO NOT

close off pressure relief value completely. This will cause pump to over heat and

shut off.

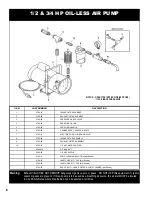

DO

before start-up, unscrew aluminum cup on exhaust filter assembly and check that

exhaust filter in firmly seated in place. Replace aluminum cup and tighten firmly.

DO

before start-up check intake filter to be sure it is secured to pump housing.

DO

change intake filter and exhaust filer every 90 to 100 running hours or if pressure

drops below recommendations.

DO

place air inlet pump in a clean air environment where breathable air can be assured

at all times.

DO

check pressure gauge for a minimum 4.0 PSI while air is flowing into supplied-air

respirator. Pressure relief valve is factory set to deliver more than the minimum

OSHA required 4.0 CFM.

DO

use grounded electrical connections.

1

Summary of Contents for Opti-Fit 9800-25

Page 15: ...11...