© 2008 S.A.S. of Luxemburg, Ltd.

To: Company:

From: _ ___________________, Ltd. Date:___/___/___

Attention:

Contact Person: ________________

____

Phone: (

)

Machine Make:

___________

Fax

No.:(

)

Machine

Model:

____

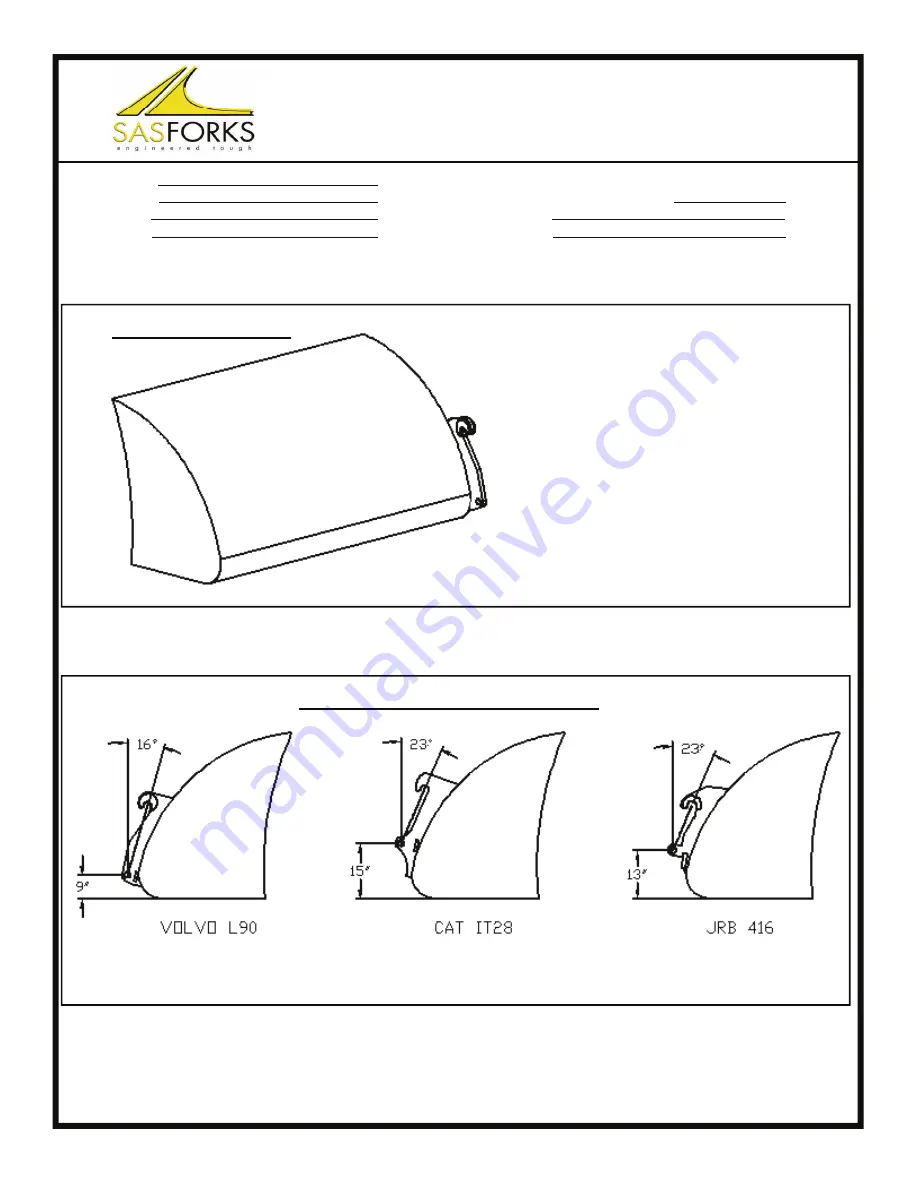

COUPLER RIB INSTALLATION

Clamp or tack weld coupler hook on the

side of bucket check angle before moving

to next step. Scribe contour of bucket pro-

file into rib. Remove from bucket and cut

with plasma or torch. Install contoured

coupler hooks into male master on machine

and position against back of bucket. Tack

to bucket and unhook from male master

( machine side ). Place strong backs across

hooks to prevent movement and finish

weld with 5/8” weld, remove strong backs

and clean tacks from hooks and bucket.

Use only 7018 low hydrogen rod or similar wire

(Met 71, 0.52”, solid core wire)

www.sasforks.com

Specifications on other machines may very and as much as SAS attempts to have as much

information on hand some buckets have differences unknown to SAS. These are recommen-

dations and customer may need to modify from these directions.

Side view setting proper angle and hook height

Contouring hooks to bucket

Summary of Contents for Male Master

Page 11: ...Page 10...

Page 13: ...EURO VOLVO L45 L120 TYPE INTERFACE PARTS LIST...