1.5. Filter stage (E):

Except for the filter cartridge, the activated charcoal filter 264 is identical in construction to the filter stage (B). The

activated charcoal cartridge, art. # 85373 is integrated in the filter. Please ensure that the activated charcoal filter is

always directly installed behind the condensate separator and the fine filter stage.

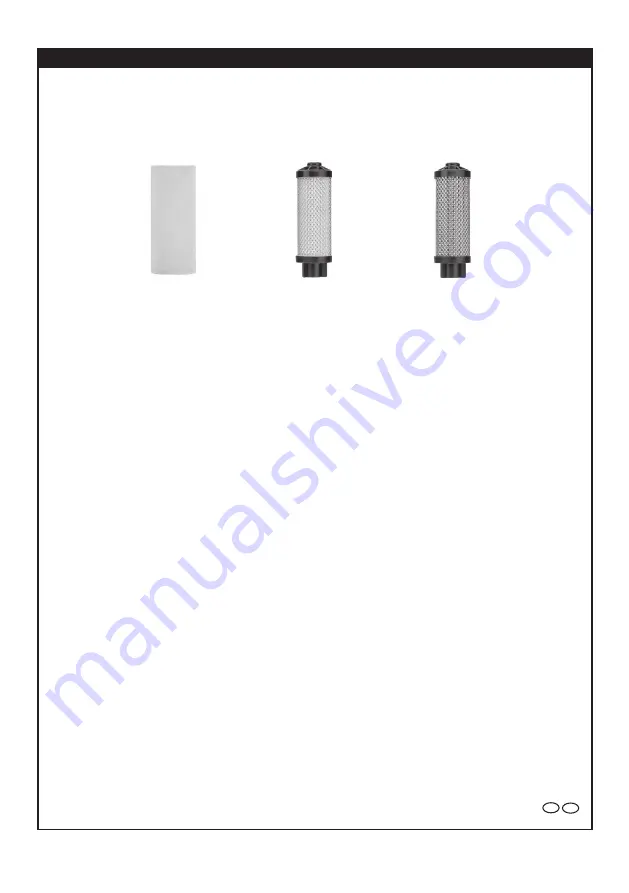

1.6. Filter Carttridges

Typ:

In case of extreme contamination,

fi

lters should be checked and, if necessary, replaced more frequently. The sintered bronze

fi

lter

and the

fi

lter housing tube (5, 8) must be cleaned every six months at the latest, if necessary, replace sintered bronze

fi

lter cartridge.

Saturated

fi

lter cartridges bear the danger of functional defaults during painting resp. affecting the painter‘s health while using sup-

plied-air respirator systems.

2. Technical Data And Specifications

Air inlet G 1/2 inside thread

10 bars/145 psi Maximum inlet operating pressure

10 bars/145 psi Maximum outlet operating pressure

Air flow rated at > 2000 Nl/min (72 cfm) at 6 bars/90 psi (see graph)

Max. surrounding temperature 120° C, with activated charcoal max. 60° C

Weight:

SATA filter

244 = 4,3 kg

264 = 1,3 kg

284 = 5,6 kg

3. Mounting The Unit

Using the included holding angles (10), the filter must be firmly mounted in the vertical position at the two mounting

holes. Ensure that the unit is mounted in a manner to protect against outside mechanical influence such as bumping

or shaking. The filter may also be mounted vertically and firmly to compressed air lines without mounting to the wall

(Mount air lines accordingly).

Screw in fitting (no. 4). Ensure tight fit and tension free assembly. For maintenance, it is recommended to include shut-

off valve with removable coupling at the air inlet (a coupling may also be put at the air outlet).

Connect one end of the condensate drain hose (no. 7) on the brass connection piece and the other end into an appro-

priate condensate storage container. Make sure that the container will not tip and the hose will not jump out when

condensate is blown.

ATTENTION!

Condensate is hazardous waste.

Operating instructions SATA filter 200

IRL

GB

Sinter

fi

lter cartridge

Sinterd bronze 5

μ

m,

surface area 100 cm², solvent

regenerable

Replacement interval every

six months

Art. No. 22160

Fine

fi

lter cartridge

, Poly-

propylene Micro Fibre layer

Surface area 300 cm² Filtering

capacity 0,01

μ

m 99,998 %

separation, non-regenerable

Replacement interval every

six months, at the latest when

the maximum pressure diffe-

rence between inlet and outlet

pressure is 1 bar/14.5 psi

Art. No. 81810

Activated charcoal cartridge

non-regenerable

Replacement interval every

three months

Art. No. 85373