418

US

Operating Instructions SATAjet 1000 B RP/HVLP

Danger! Notice!

•

After cleaning, the spray gun, the material passages, the air cap

including thread as well as the gravity flow cup have to be blown

dry with clean compressed air!*

* otherwise risk of corrosion

Information!

• Check spray pattern after cleaning the nozzle set!

• Further cleaning tips can be found at www.sata.com/TV.

9. Maintenance

Danger! Notice!

• Prior to maintenance, disconnect paint spray gun from the compressed

air circuit!

• Disassemble and install components very carefully! Exclusively use

included special tools!

9.1. Replacing the Nozzle Set

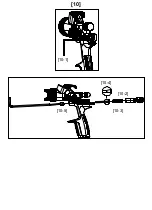

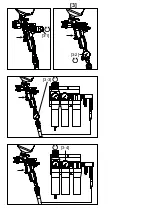

[7-1], [7-2], [7-3], [7-4], [7-5]

and [7-6]

Every SATA nozzle set consists of "paint needle"

[7-1]

, "air cap"

[7-2]

and "fluid tip"

[7-3]

and has been hand-adjusted to provide a perfect

spray pattern. Therefore, always exchange the complete nozzle set. After

installation, please adjust material flow according to chapter 7.2.

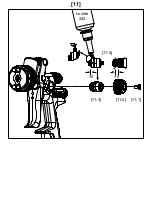

9.2. Replacing the Air Distribution Ring Steps:

[7-1],

[7-2], [7-3], [8-1], [8-2] [8-3], [7-4], [7-5] and [7-6]

Notice!

• Remove air distribution ring with SATA extraction tool only.

• Do not apply force to avoid damage of sealing surfaces.

Summary of Contents for jet 1000 B

Page 20: ......

Page 110: ......

Page 128: ......

Page 143: ...143 FI Käyttöohje SATAjet 1000 B RP HVLP Albrecht Kruse Toimitusjohtaja SATA GmbH Co KG ...

Page 144: ......

Page 162: ......

Page 213: ...213 IT Istruzione d uso SATAjet 1000 B RP HVLP Albrecht Kruse Amministratore SATA GmbH Co KG ...

Page 214: ......

Page 230: ......

Page 262: ......

Page 278: ......

Page 296: ......

Page 378: ......

Page 410: ......

Page 426: ......

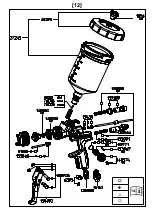

Page 428: ... 10 10 1 10 2 10 4 10 5 10 3 ...

Page 429: ... 11 11 1 11 2 11 3 11 4 Loctite 242 0 0 ...

Page 430: ... 14 12 ...

Page 431: ... 3 4 3 3 2 3 3 3 1 ...

Page 432: ... 4 5 6 4 3 4 4 6 1 4 1 5 1 5 2 0 0 90 90 6 2 6 2 4 2 ...

Page 433: ... 7 8 7 2 7 3 7 1 7 5 7 4 7 6 14 Nm 8 1 8 2 8 3 12h ...

Page 434: ... 9 9 1 9 3 9 2 ...