121

EN

Operating instructions SATAminijet 1000 K/H RP/HVLP

Operating instructions SATAminijet 1000 K/H RP/HVLP

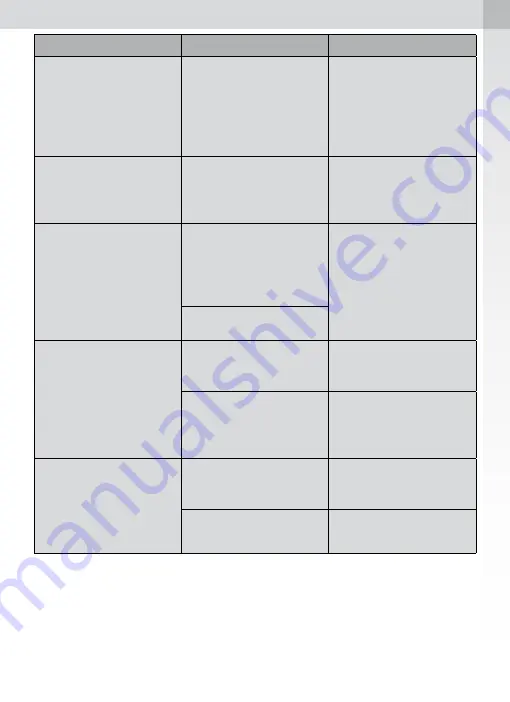

Malfunction

Cause

Corrective Action

Round/flat spray con

-

trol cannot be regu-

lated

Control has been

turned too much in

counterclockwise di-

rection; spindle has

loosened inside the

spray gun thread

Remove the control

with universal spanner;

rectify or replace com-

pletely, chapter 9.6

Spray gun does not

shut-off air

Clogged air piston seat

or worn air piston

Clean air piston seat

and/or replace air pis-

ton, air piston packing,

chapter 9.4

Corrosion on air cap

thread, inside material

passages (cup con-

nection) or on spray

gun body

Cleaning solution

(water-based) remains

inside/on the spray

gun for too long.

Cleaning, observe

chapter 8

, get a re-

placement spray gun

body

Unsuitable cleaning

media

Material leaks from

behind the paint nee-

dle seal

Defective or missing

paint needle seal

Replace / insert paint

needle seal, chapter

9.3

Clogged or damaged

paint needle.

Replace nozzle set,

chapter 9.1; replace

paint needle seal, if

necessary, chapter 9.3

Spray gun leaks from

the fluid tip ("fluid tip

aperture")

Contamination be-

tween paint needle tip

and fluid tip

Clean fluid tip and

paint needle, observe

chapter 8

Damaged nozzle set

Replace nozzle set,

chapter 9.1

11. Disposal

Recycle the completely empty spray gun. To protect the environment, bat-

teries and residual paint have to be disposed in an appropriate way and

separately from the spray gun. Please observe local legislation!