120

EN

Operating instructions SATAminijet 1000 K/H RP/HVLP

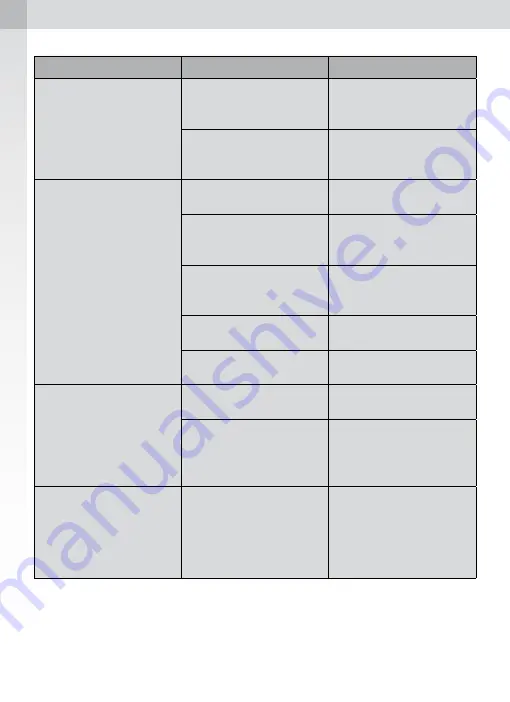

10. Trouble-shooting

Malfunction

Cause

Corrective Action

Fluttering/Spitting

spray fan or air bub-

bles appearing in the

suction cup

Fluid tip has not been

properly tightened

Tighten fluid tip

[2-1]

with universal spanner

[7-4]

Air distribution ring is

damaged or clogged.

Replace air distribution

ring which will be dam-

aged during extraction

Air bubbles appearing

in the suction cup

Loose air cap

Tighten air cap

[2-2]

by hand

Gap between air cap

and fluid tip ("air cir

-

cuit") is clogged

Clean air circuit, ob-

serve chapter 8

Nozzle set is clogged

or damaged

Clean the nozzle set,

chapter 8, or replace,

chapter 9.1

Not enough paint ma-

terial in the suction cup

Refill suction cup

Defective paint needle

seal

Replace the paint nee-

dle seal, chapter 9.3

Spray pattern is too

small, crooked, lop-

sided or splitting

Clogged air cap drill-

ings

Clean air cap, observe

chapter 8

Damaged fluid tip (fluid

tip aperture)

Check if fluid tip is

damaged, replace the

nozzle set, if neces-

sary, chapter 9.1

No function of round/

flat spray control - con

-

trol knob can still be

turned

Air distribution ring has

not been positioned in

correct location (pin is

not located in the drill-

ing) or damaged

Replace the air dis-

tribution ring making

sure it has been posi-

tioned correctly when

inserting it, chapter 9.2