<< Operating Instructions SATAjet 1000-110/-111/-120/-121 >>

<< Operating Instructions SATAjet 1000-110/-111/-120/-121 >>

EN

III.7

<< English >>

inlet pressure per every 10 m of air hose (inner width 9 mm).

7.2. Adjustment of the Material Flow

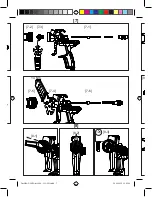

[4-1], [4-2], [4-3]

und [4-4] - material flow control fully opened

Notice!

With the material flow control fully opened, the wear of the fluid tip and

paint needle is reduced to a minimum. Please select the correct nozzle

size depending on the material to be applied and the required applica-

tion speed.

7.3. Adjustment of the Spray Fan Pattern

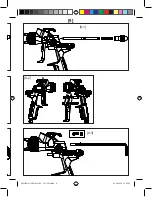

• Adjust flat fan (factory setting)

[5-1]

.

•

Adjust round fan

[5-2]

.

7.4. Painting

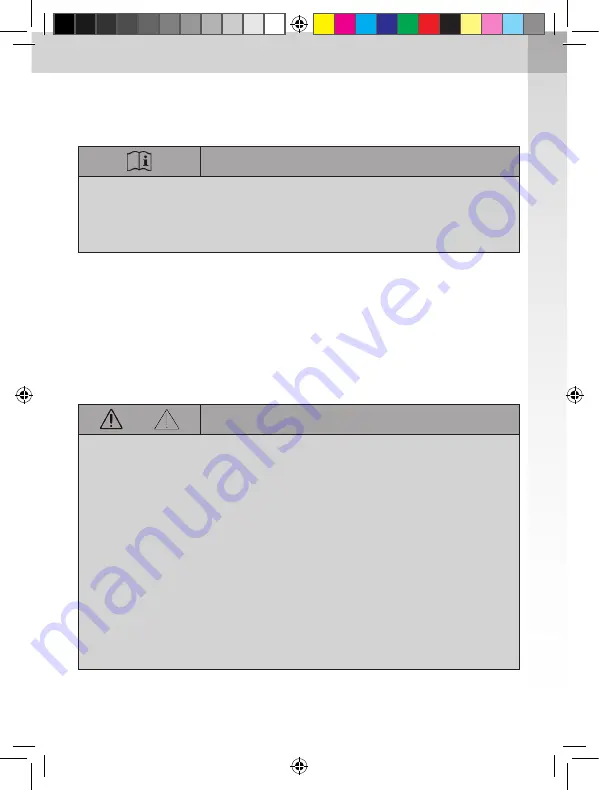

Fully pull trigger for painting

[6-1]

. Operate spray gun according to

[6-2]

.

Maintain spray distance as described in chapter 2.

8. Cleaning of the Spray Gun

Warning! Attention!

•

Prior to cleaning, please disconnect the spray gun from the com-

pressed air circuit!

•

Risk of injury due to unexpected leakage of compressed air or mate-

rial!

• Empty spray gun and gravity flow cup completely, dispose of paint

material appropriately!

•

Disassemble and install components very carefully! Exclusively use

included special tools!

•

Use neutral cleaning solution (pH value 6 to 8)!*

•

Do not use acids, lyes, pickling agents, unsuitable re-

claimed materials or other aggresive cleaning media, such

as Toluol, for example!*

•

Do not soak spray gun in cleaning solution!*

EN-BAL-SATAjet 1000 -111 -121.indd 7

29.10.2012 12:11:06

Summary of Contents for SATAjet 1000 Series

Page 34: ...BAL_jet4000_2 indd 18 29 10 2012 12 23 01...

Page 51: ...BAL_jet4000_2 indd 19 29 10 2012 12 23 01...

Page 52: ...BAL_jet4000_2 indd 18 29 10 2012 12 23 01...

Page 56: ...9 9 1 9 3 9 2 Titel BAL SATAjet 1000 111 121 indd 8 24 10 2012 11 02 15...

Page 57: ...10 10 1 10 2 10 4 10 5 10 3 Titel BAL SATAjet 1000 111 121 indd 9 24 10 2012 11 01 34...

Page 59: ...14 13 11 1 Titel BAL SATAjet 1000 111 121 indd 11 24 10 2012 11 01 40...