<< Operating Instructions SATAjet 1000-110/-111/-120/-121 >>

III.12

EN

Malfunction

Cause

Corrective Action

Round/flat spray con

-

trol cannot be regu-

lated

Control has been

turned too much in

counterclockwise di-

rection; spindle has

loosend inside the

spray gun thread

Remove control with

universal spanner;

rectify or replace com-

pletely, chapter 9.6

Spray gun does not

shut-off air

Clogged air piston seat

or worn air piston.

Clean air piston seat

and/or replace air pis-

ton, air piston packing,

chapter 9.4

Corrosion on air cap

thread, inside material

passages (cup con-

nection) or on spray

gun body

Cleaning solution

(water-based) remains

inside/on the spray

gun for too long.

Cleaning, observe

chapter 8, get a

replacement spray

gun body.

Unsuitable cleaning

solutions

Material leaks from

behind the paint nee-

dle sealing

Defective or missing

paint needle sealing.

Replace / insert paint

needle sealing, chap-

ter 9.3

Clogged or damaged

paint needle.

Replace nozzle set,

chapter 9.1; replace

paint needle sealing, if

necessary, chapter 9.3

Spray gun leaks from

the fluid tip ("fluid tip

aperture")

Contamination be-

tween paint needle tip

and fluid tip

Clean fluid tip and

paint needle, observe

chapter 8

Damaged nozzle set.

Replace nozzle set,

chapter 9.1

11. Disposal

Recycle the completely empty spray gun. To protect the environment, bat-

teries and residual paint have to be disposed in an appropriate way and

separately from the spray gun. Please observe local legislation!

EN-BAL-SATAjet 1000 -111 -121.indd 12

29.10.2012 12:11:07

Summary of Contents for SATAjet 1000 Series

Page 34: ...BAL_jet4000_2 indd 18 29 10 2012 12 23 01...

Page 51: ...BAL_jet4000_2 indd 19 29 10 2012 12 23 01...

Page 52: ...BAL_jet4000_2 indd 18 29 10 2012 12 23 01...

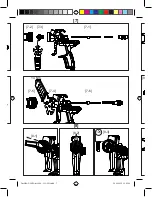

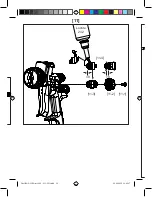

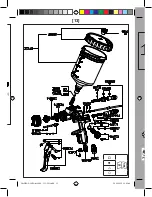

Page 56: ...9 9 1 9 3 9 2 Titel BAL SATAjet 1000 111 121 indd 8 24 10 2012 11 02 15...

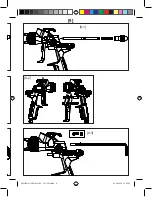

Page 57: ...10 10 1 10 2 10 4 10 5 10 3 Titel BAL SATAjet 1000 111 121 indd 9 24 10 2012 11 01 34...

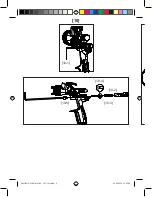

Page 59: ...14 13 11 1 Titel BAL SATAjet 1000 111 121 indd 11 24 10 2012 11 01 40...