113

US

Operating Manual SATAjet 4600 B RP/HVLP

• Make sure that the spindle pick-up is free of material and paint resi-

dues, remove residues and clean with solvent, if necessary

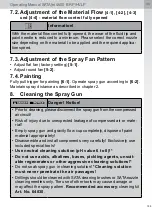

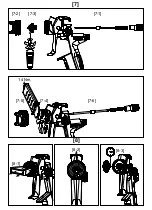

2. Installation and position of new spindle [a, b]

• Screw in spindle [11-3]

•

Turn spindle nut [11-3] to position 6 o’clock using a wrench (size 6)

[11-4]

3. Positioning and assembly of control knob [c]

•

Position of knob [11-2] has to be according to illustration (line in the

knob has to be in vertical position)

•

Hand-tighten screw [11-1] (Torx T20) in the knob - hold knob in the

position while tightening

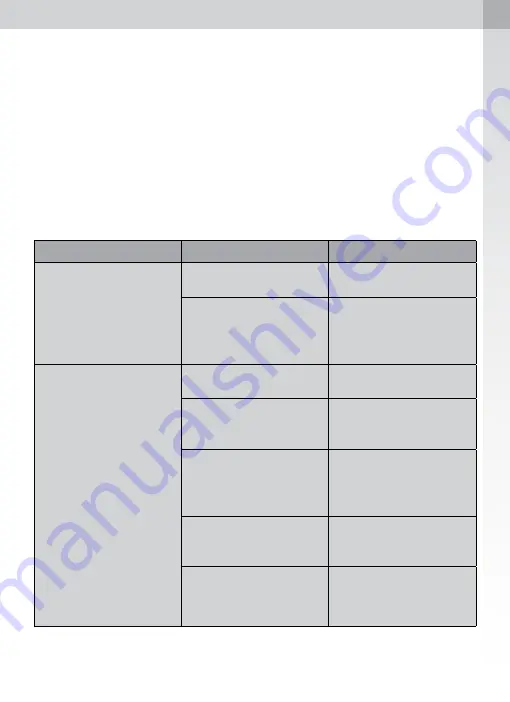

10. Troubleshooting

Malfunction

Cause

Corrective action

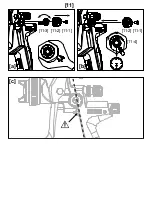

Fluttering/spitting

spray fan or air bub-

bles appearing in the

gravity flow cup

Fluid tip has not been

properly tightened

Tighten fluid tip

[2-1]

with universal spanner

Air distribution ring is

damaged or clogged.

Replace air distribu-

tion ring, as it will be

damaged during disas-

sembly

Air bubbles appearing

in the gravity flow cup

Loose air cap

Tighten air cap

[2-2]

by hand

Gap between air cap

and fluid tip ("air cir-

cuit") is clogged

Clean air circuit, ob-

serve chapter 8

Nozzle set is clogged

or damaged

Clean nozzle set,

chapter 8, or replace,

respectively, chapter

9.1

Not enough paint ma-

terial in the gravity flow

cup

Refill gravity flow cup

[1-6]

Defective paint needle

sealing

Replace the paint nee-

dle sealing, chapter

9.3

Summary of Contents for SATAjet 4600 B

Page 4: ... 2 2 2 2 1 2 4 2 3 2 5 2 7 2 8 2 9 2 6 2 10 2 11 2 12 2 13 2 14 ...

Page 20: ......

Page 34: ......

Page 84: ......

Page 120: ......

Page 121: ... 10 10 1 10 2 10 4 10 5 10 3 10 6 ...

Page 122: ... 11 a c b 11 1 11 2 11 1 11 2 11 3 11 4 ...

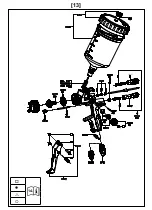

Page 123: ... 13 14 222489 ...

Page 126: ... 3 3 4 3 2 3 3 3 1 ...

Page 127: ... 4 5 6 4 3 4 4 6 1 4 1 5 1 5 2 0 0 90 90 6 2 6 2 4 2 ...

Page 128: ... 7 8 7 2 7 3 7 1 7 5 7 4 7 6 14 Nm 8 1 8 2 8 3 ...

Page 129: ... 9 9 1 9 3 9 2 3 1 2 ...

Page 130: ......