114

Operating Manual SATAjet 4600 B RP/HVLP

US

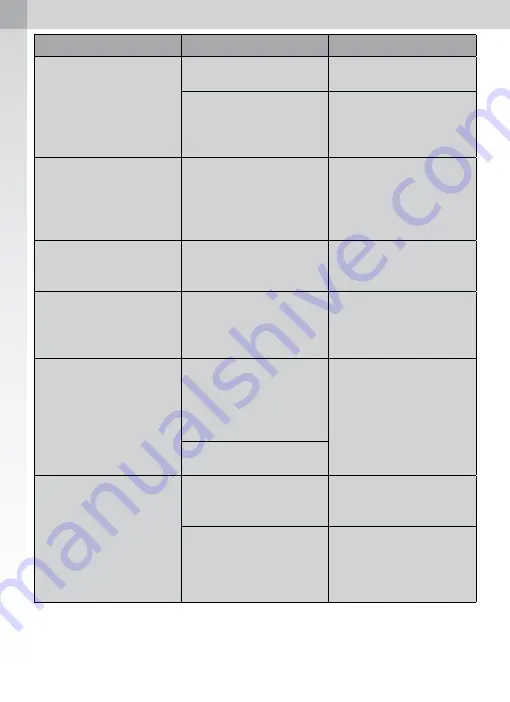

Malfunction

Cause

Corrective action

Spray pattern is too

small, crooked, lop-sid-

ed or splitting

Clogged air cap drill-

ings

Clean air cap, observe

chapter 8

Damaged fluid tip (fluid

tip aperture)

Check if fluid tip is

damaged, replace the

nozzle set, if neces-

sary, chapter 9.1

No function of round/

flat fan control - control

knob can still be turned

Air distribution ring has

not been positioned in

correct location (pin is

not located in the drill-

ing) or damaged

Replace air distribution

ring making sure it has

been positioned cor-

rectly when inserting it,

chapter 9.2

Round/flat fan control

cannot be regulated

Regulation valve dirty Remove round/flat fan

control, repair or re-

place it, chapter 9.7

Spray gun does not

shut-off air

Clogged air piston seat

or worn air piston

Clean air piston seat

and/or replace air pis-

ton, air piston packing,

chapter 9.4

Corrosion on air cap

thread, inside material

passages (cup con-

nection) or on spray

gun body

Cleaning solution

(water-based) remains

inside/on the spray

gun for too long

Cleaning, observe

chapter 8

, get a re-

placement spray gun

body.

Unsuitable cleaning

solutions

Material leaks from

behind the paint nee-

dle sealing

Defective or missing

paint needle sealing

Replace / insert paint

needle sealing, chap-

ter 9.3

Clogged or damaged

paint needle

Replace nozzle set,

chapter 9.1; replace

paint needle sealing, if

necessary, chapter 9.3

Summary of Contents for SATAjet 4600 B

Page 4: ... 2 2 2 2 1 2 4 2 3 2 5 2 7 2 8 2 9 2 6 2 10 2 11 2 12 2 13 2 14 ...

Page 20: ......

Page 34: ......

Page 84: ......

Page 120: ......

Page 121: ... 10 10 1 10 2 10 4 10 5 10 3 10 6 ...

Page 122: ... 11 a c b 11 1 11 2 11 1 11 2 11 3 11 4 ...

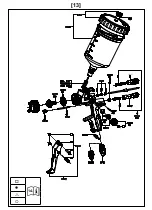

Page 123: ... 13 14 222489 ...

Page 126: ... 3 3 4 3 2 3 3 3 1 ...

Page 127: ... 4 5 6 4 3 4 4 6 1 4 1 5 1 5 2 0 0 90 90 6 2 6 2 4 2 ...

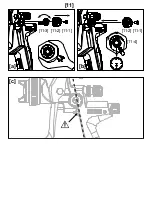

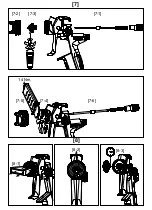

Page 128: ... 7 8 7 2 7 3 7 1 7 5 7 4 7 6 14 Nm 8 1 8 2 8 3 ...

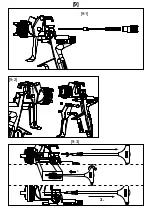

Page 129: ... 9 9 1 9 3 9 2 3 1 2 ...

Page 130: ......