125

EN

Operating Manual SATAjet X 5500 RP/HVLP (DIGITAL)

Operating Manual SATAjet X 5500 RP/HVLP (DIGITAL)

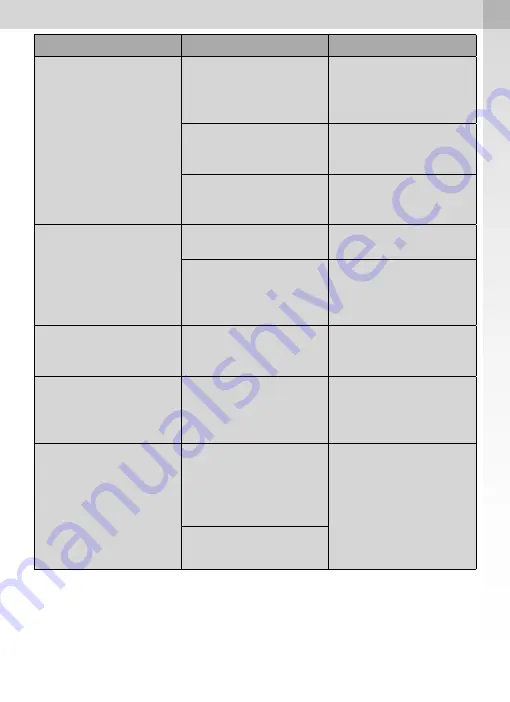

Malfunction

Cause

Corrective action

Nozzle set is clogged

or damaged

Clean nozzle set,

chapter 8, or replace,

respectively, chapter

9.1

Air bubbles appearing

in the gravity flow cup

Not enough paint ma-

terial in the gravity flow

cup

Refill gravity flow cup

[1-6]

Defective paint needle

sealing

Replace the paint nee-

dle sealing, chapter

9.3

Spray pattern is too

small, crooked, lop-sid-

ed or splitting

Clogged air cap drill-

ings

Clean air cap, observe

chapter 8

Damaged fluid tip (fluid

tip aperture)

Check if fluid tip is

damaged, replace the

nozzle set, if neces-

sary, chapter 9.1

Round/flat fan control

cannot be regulated

Regulation valve dirty Remove round/flat

spray control, repair or

replace it, chapter 9.7

Spray gun does not

shut-off air

Clogged air piston seat

or worn air piston.

Clean air piston seat

and/or replace air pis-

ton, air piston packing,

chapter 9.4

Corrosion on air cap

thread, inside material

passages (cup con-

nection) or on spray

gun body

Cleaning solution

(water-based) remains

inside/on the spray

gun for too long.

Cleaning, observe

chapter 8, get a

replacement spray

gun body.

Unsuitable cleaning

solutions

Summary of Contents for SATAjet X 5500

Page 3: ...10 11 12 25 13 14 12 14 ...

Page 4: ... 1 1 7 1 9 1 3 1 11 1 12 1 13 1 14 1 15 1 1 1 2 1 4 1 8 1 18 1 19 1 5 1 10 1 16 1 17 1 6 ...

Page 22: ......

Page 58: ......

Page 94: ......

Page 112: ......

Page 130: ......

Page 150: ......

Page 168: ......

Page 244: ......

Page 316: ......

Page 336: ......

Page 356: ......

Page 412: ......

Page 430: ......

Page 466: ......

Page 484: ......

Page 487: ......

Page 488: ......

Page 489: ... 8 ...

Page 490: ... 9 ...

Page 491: ... 10 11 ...

Page 494: ... 2 ...

Page 495: ... 3 ...

Page 496: ... 4 5 ...

Page 497: ... 7 6 ...

Page 498: ......