SATEL

INTEGRA 128-WRL

21

system should be instructed on how to disconnect the transformer from the mains (e.g. by

indicating the fuse which protects the control panel supply circuit).

5.9.2 Backup power supply

A 12 V lead-acid sealed battery should be connected to the control panel as a backup power

source. The battery capacity must be adequately selected to match current consumption in

the system. According to EN 50131 Grade 2, the battery must ensure operation of the system

without mains supply for 12 hours.

Do not connect deeply discharged battery to the control panel (with voltage

across unloaded terminals below 11 V). The battery should be precharged with

a proper charger.

The used batteries must not be discarded, but should be disposed of in

accordance with the existing rules for environment protection.

If the battery voltage drops below 11 V for longer than 12 minutes (3 battery tests), the

control panel will indicate battery failure. When the voltage goes down to approx. 10.5 V, the

battery will be disconnected.

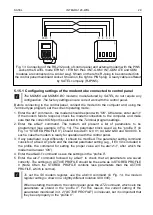

5.9.3 Control panel power-up / start-up procedure

1. Deenergize the 230 V AC circuit to which the transformer is to be connected.

2. Connect the 230 V AC wires to the terminals of transformer primary winding.

3. Connect the terminals of transformer secondary winding to the AC terminals on control

panel electronics board.

4. Connect the battery to the dedicated leads (positive terminal to RED lead, negative

terminal to BLACK lead).

The control panel will not start after connecting the battery

alone.

Included in the control panel set are adapters (matching connectors) for

connection of battery with twisted cable ends, therefore the battery cable ends should not

be cut off.

5. Turn on 230 V AC power supply in the circuit to which the transformer is connected.

The control panel will start operating.

If you have any problems with starting the control panel, enter the service mode

“from the pins” and restore the factory default settings (see E

MERGENCY

PROCEDURE OF THE CONTROL PANEL START

-

UP

p. 22).

The above mentioned power-up sequence (first the battery, then the 230 V AC mains) will

ensure proper operation of the power supply unit and the electronic protection circuits, thus

preventing damage to the alarm system components caused by installation mistakes, if any.

If the control panel power supply has to be disconnected, disconnect the mains first

and then the battery. When reconnecting the power supply, observe the above

mentioned sequence.

5.10 First start-up of the control panel

After the first start-up of the control panel, it is advisable to restore the factory

default settings using the C

LEAR ALL

function ([S

ERVICE CODE

]

S

ERVICE MODE

R

ESTARTS

C

LEAR ALL

), and then quit the service mode. When a prompt

appears on the keypad display, whether the data should be saved to the FLASH

memory, press the “1” key on the keypad.