Instructions for use of

etc-12/etd

G Series Direct Replacement Trip Unit

page

5 of 13

revision B,

8/20/10

1.0 Required Tools:

1.1.

Installation of this trip unit does not

require tools but since minor repairs and

adjustments are generally made at the same

time as the trip unit is upgraded, it is

recommended that a full set of basic hand

tools be available. When upgrading the trip

unit on breakers above 2000A, an included

jumper must be added to the existing wiring

harness. If this modification is required, it is

recommended that the pin extraction tool

listed in table 1 be available. This is because

it is not possible to remove and reposition the

jumper without the tool if it inserted

incorrectly in error. The table lists several

commercial sources of this tool. It can also

be obtained through

Satin American.

Table 1

Sources for TYCO/AMP pin extraction tool #455822-2

Source

Phone / URL

Stock

Number

Allied

Electronics

(866) 433-5722

http://www.alliedelec.com/

527-0181

Digi-Key

Corporation

(800) 344-4539

http://www.digikey.com/

A9954-ND

Mouser

Electronics

(800) 346-6873

http://www.mouser.com/

571-4558222

2.0

Reference Material:

2.1.

Manufacturers Circuit Breaker

Maintenance Manual.

3.0

Manual and time-current curves for

original trip unit.

3.1.

etc-12

Section II Programmer

Instruction Manual

4.0

Installation:

4.1.

Verify that the proper kit was supplied

and thoroughly inspect it for damage or

missing components.

4.2.

Read and understand these

instructions before beginning the retrofit.

4.3.

Place the breaker on a solid bench in

a clean work area were there is sufficient

access to all sides of the breaker.

4.4.

Perform a detailed mechanical

inspection of the breaker. At a minimum,

verify that the breaker opens and closes

properly. Any mechanical problems should

be fixed prior to beginning the retrofit.

Normal maintenance can be performed prior

to or during kit installation.

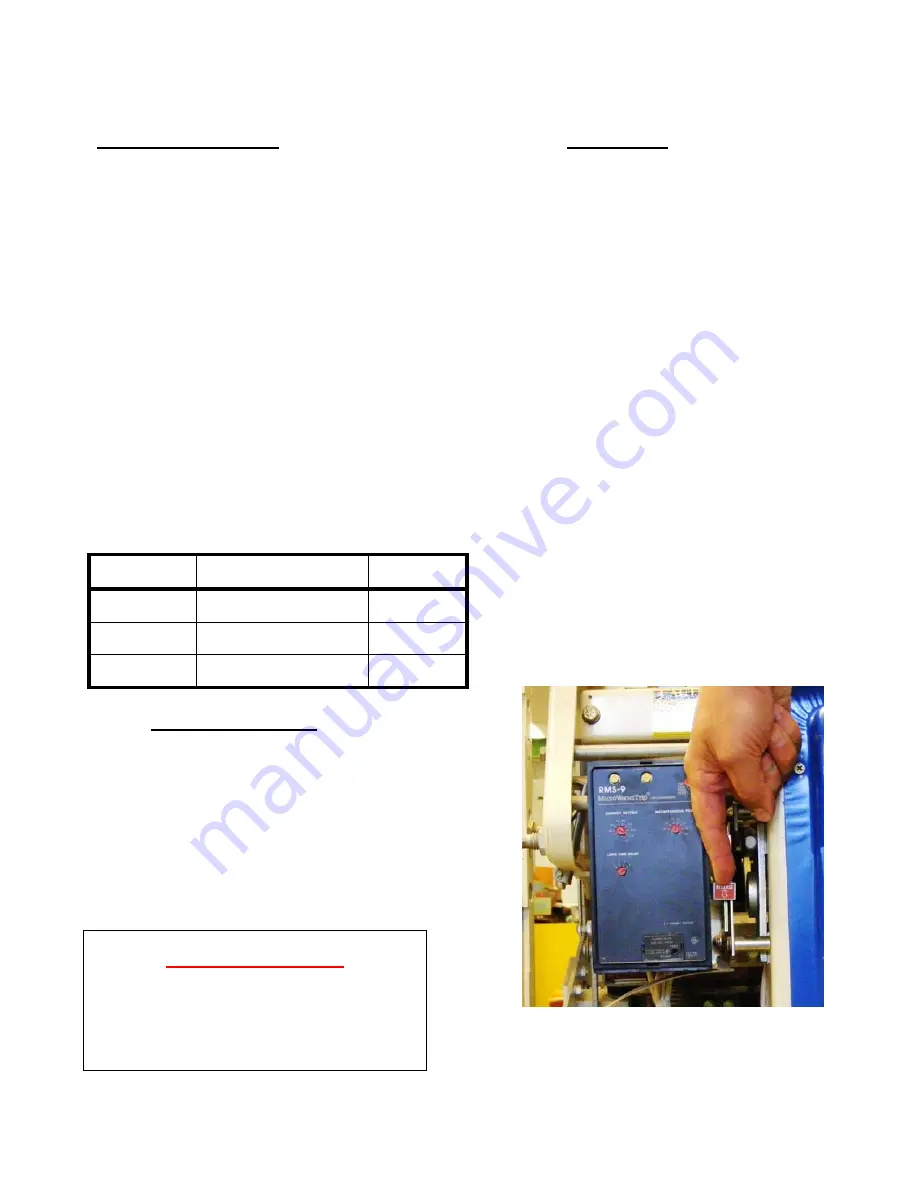

4.5.

Remove and existing solid state

tripping device by sliding the

RELEASE

leaver on the existing programmer mount.

See figure 1. Before discarding original trip

unit, be sure to make note of settings.

IMPORTANT!!

BEFORE PROCEEDING, VERIFY

THAT THE BREAKER IS OPEN AND

CHARGING SPRINGS ARE

DISCHARGED

FIGURE 1, REMOVING EXISTING TRIP UNIT

Summary of Contents for etc-12 G series

Page 2: ...Intentionally Blank ...

Page 14: ......