3:

J

OB

S

ETUP

pn 9386295-01

39

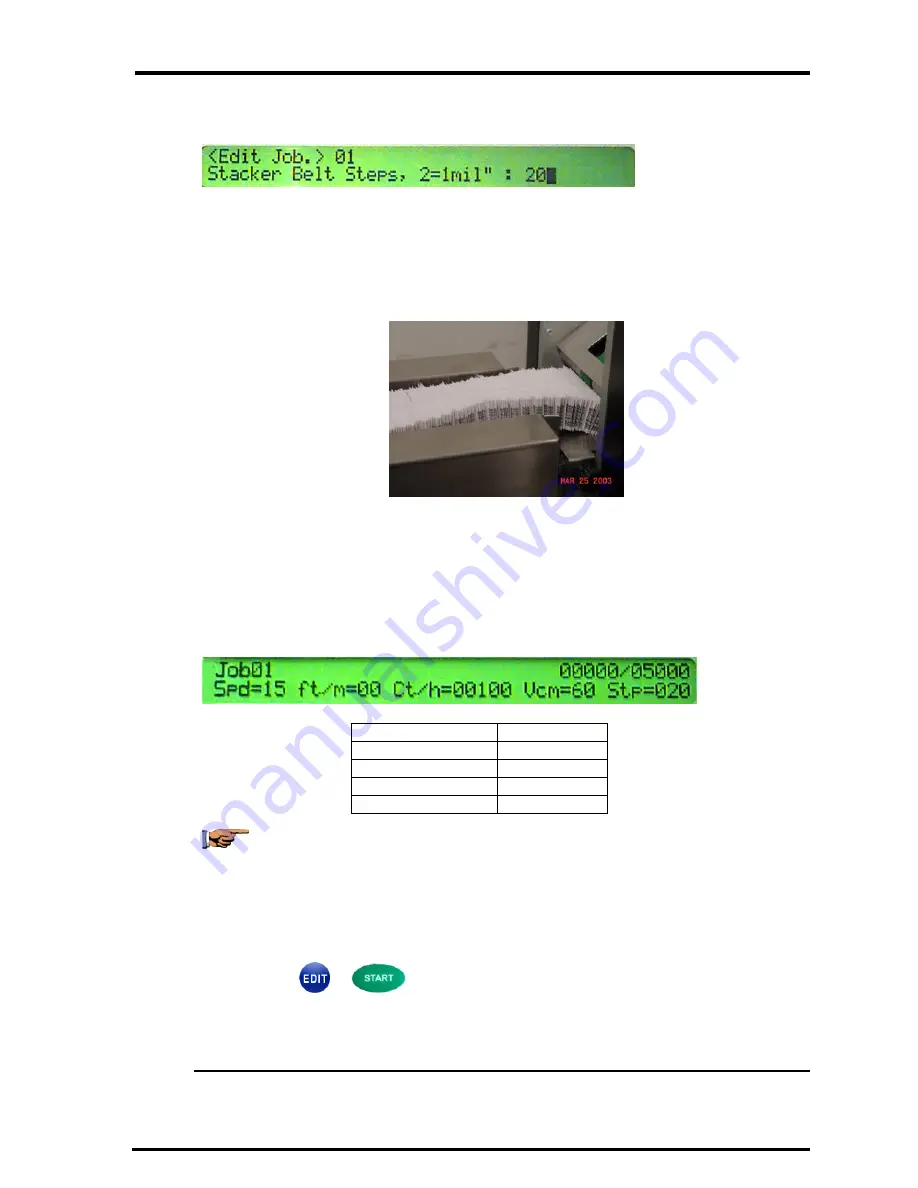

3.3.10. Stacker Belt Step, 2=1mil”

This setting will change how tightly the tickets are stacked together on the exit conveyor. A

tighter stack will mean more tickets stacked; however, stacking too tightly will cause a jam.

Ideally the stack should have a very slight amount of play in it. The stack is too tight if it is

lifting as shown in the photo below.

•

Start with the settings provided in the following chart and, while running, fine tune

from there by pressing “2” to create a tighter stack or “3” to loosen the stack.

•

Once you have determined the ideal conveyor speed (displayed as Stp=###), enter

that setting in the “Stacker Belt Step” screen.

# of tickets per cut

Initial Setting

7

15

9

17

13

19

17

24

Note: These are initial guideline settings. Your actual settings will be dependent

on the materials and applications.

3.3.11. Saving the Job Settings

•

Press

or

to save the job and leave set up.

3.4. C

ANCEL A

P

ASSWORD

Entering the password “000” or cycling the main power switch will cancel any password.

Summary of Contents for CS-9018

Page 1: ...CS 9018 Cutter Stacker Operator s Guide Part No 9386295 01 February 2021...

Page 2: ...Inside front cover...

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK...

Page 20: ...CS 9018 OPERATOR S GUIDE 20 pn 9386295 01 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 42: ...CS 9018 OPERATOR S GUIDE 42 CS 9018 Operator s Guide THIS PAGE INTENTIONALLY LEFT BLANK...

Page 54: ...CS 9018 OPERATOR S GUIDE 54 CS 9018 Operator s Guide 6 2 KEYBOARD OVERLAYS...

Page 57: ......

Page 58: ...8 or 9 Form Adjust 2 or 3 Conveyor Speed 1 Loosen Stacker 4 Tighten Stacker Select Job...

Page 60: ...CS 9018 Operator s Guide THIS PAGE INTENTIONALLY LEFT BLANK...

Page 61: ...Inside back cover...