CS-9018

O

PERATOR

’

S

G

UIDE

48

CS-9018 Operator’s Guide

4.2. W

HEN ERROR OR INFORMATION MESSAGES ARE DISPLAYED

When error messages or information are displayed, detect the error code in the upper line

of the display and perform the initial action for that error as listed in the “ERROR CODES”

chart located in this section. To reset the error press RESET.

If the problem persists, contact your service center.

4.2.1.

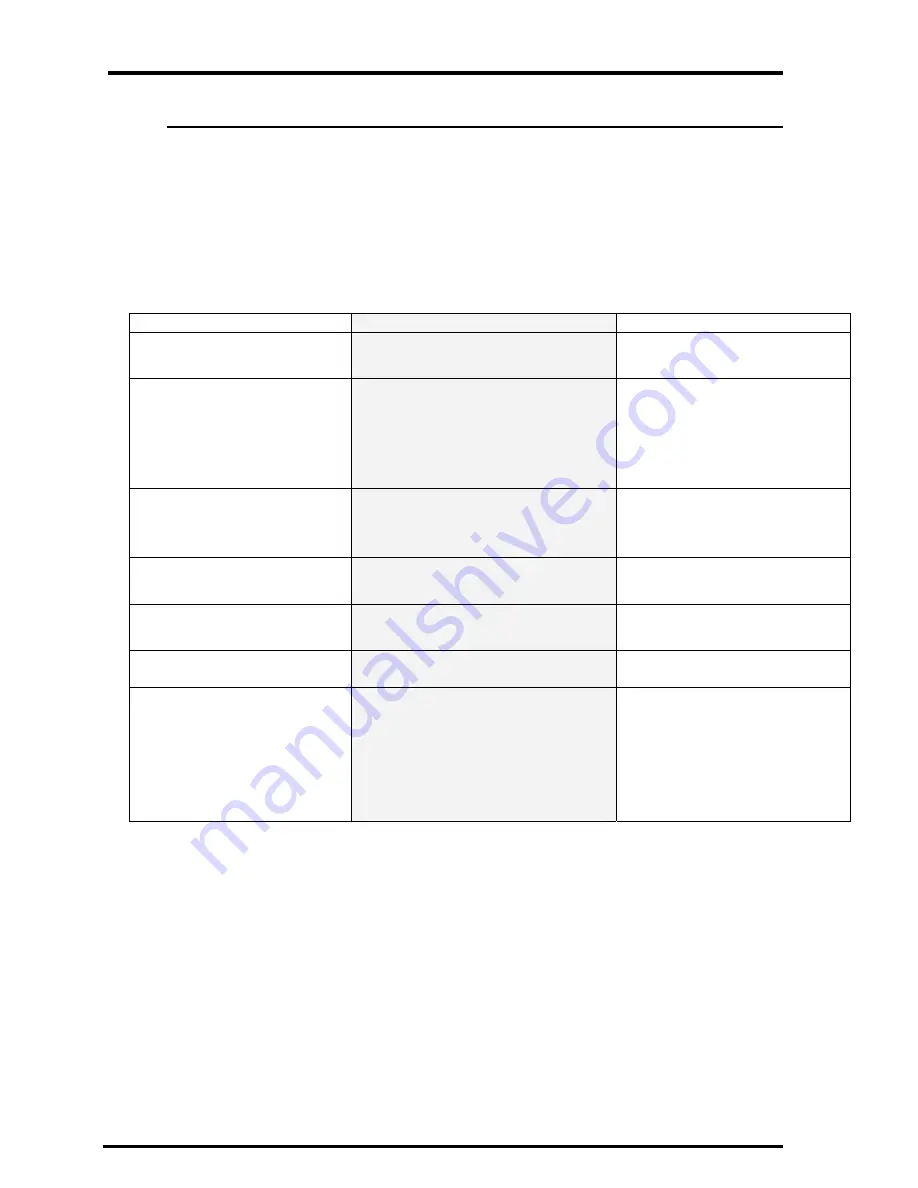

Operator Troubleshooting Guide

PROBLEM:

POSSIBLE CAUSE

SOLUTION

Machine ON with blank display or display off.

1. Is machine plugged in?

1. Plug the CS-9018 in.

Tickets are not cut on the perf.

1. Parameter is set incorrectly.

2. Job is set up incorrectly.

1. Press 8 or 9 to adjust cut to perf while running.

This is a temporary fix and must be repeated

each time the forms are loaded. Have technician

check the parameter setting.

2. Adjust cut length settings for the job being run.

Can’t escape from setup mode.

Bad information on display.

1. Unknown reason for lockup or bad information.

1. Power CS-9018 off and back on.

“No Loop / Not Ready” on display.

1. Check Setup.

1. Check and adjust form loop.

2. Is cutter off line and printer on line?

Cutter stops without an error message.

1. Preset group setting has been reached.

1. Press START.

Cutter stops with “<NO LOOP>” message.

1. Forms have cleared loop sensor, if installed on your

CS-9018.

1. Reload forms or disable loop control.

Tickets do not stack well.

1. Forms are not being cut on the perf.

2. Tickets on the extended stacker are too loose or too

tight. You should be able to easily separate the tops of

the tickets and see an

⅛

” to ¼” gap.

3. The stacking conveyor infeed plate is not fully in place.

4. The vacuum transport belt holes are not aligned with

the slots in the vacuum support tube.

1. Reload forms or press 8 or 9 to fine adjust.

2. Adjust stacking conveyor speed. Once a good

speed has been established, enter that setting

into the job setup screen.

3. Loosen the two black knobs, press the plate

into position, and tighten the knobs.

4. Contact your service technician for adjustment.

Summary of Contents for CS-9018

Page 1: ...CS 9018 Cutter Stacker Operator s Guide Part No 9386295 01 February 2021...

Page 2: ...Inside front cover...

Page 4: ...THIS PAGE INTENTIONALLY LEFT BLANK...

Page 20: ...CS 9018 OPERATOR S GUIDE 20 pn 9386295 01 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 42: ...CS 9018 OPERATOR S GUIDE 42 CS 9018 Operator s Guide THIS PAGE INTENTIONALLY LEFT BLANK...

Page 54: ...CS 9018 OPERATOR S GUIDE 54 CS 9018 Operator s Guide 6 2 KEYBOARD OVERLAYS...

Page 57: ......

Page 58: ...8 or 9 Form Adjust 2 or 3 Conveyor Speed 1 Loosen Stacker 4 Tighten Stacker Select Job...

Page 60: ...CS 9018 Operator s Guide THIS PAGE INTENTIONALLY LEFT BLANK...

Page 61: ...Inside back cover...