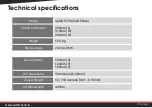

Model

Satori ST1600 3D Printer

Printer Dimension

300mm (L)

313mm (W)

362mm (H)

Weight

12.5 Kg

Power usage

24V 4A, 96W

Build Volume

192mm (X)

120mm (Y)

120mm (Z)

X/Y Resolution

50 microns (0.05mm)

Z Layer Height

10 - 150 microns (0.01 - 0.15mm)

UV Wavelength

405nm

Technical specifications

www.satori-tech.io

20 | page

Summary of Contents for ST1600

Page 1: ...GETTING STARTED WITH THE ST1600 3D PRINTER FIRST PRINT ...

Page 2: ......

Page 24: ......