INSTALLATION (continued)

IN

ST

A

LL

AT

IO

N

(C

on

tinued)

INSTALLING THE GAS GRIDDLE

Refer to the nameplate. Verify the fuel type and pressure, which must

match the nameplate specifications. Connecting the griddle to the

wrong fuel type and/or pressure will compromise the safety and/or

performance of the appliance.

BE SURE TO MAINTAIN REQUIRED CLEARANCES TO COMBUSTIBLE

SURFACES.

The griddle must be placed in its final operational position and leveled

front-to-back and side-to-side, with a spirit level, prior to beginning the

gas piping installation. Re-check the level of the unit at the conclusion

of the gas piping installation.

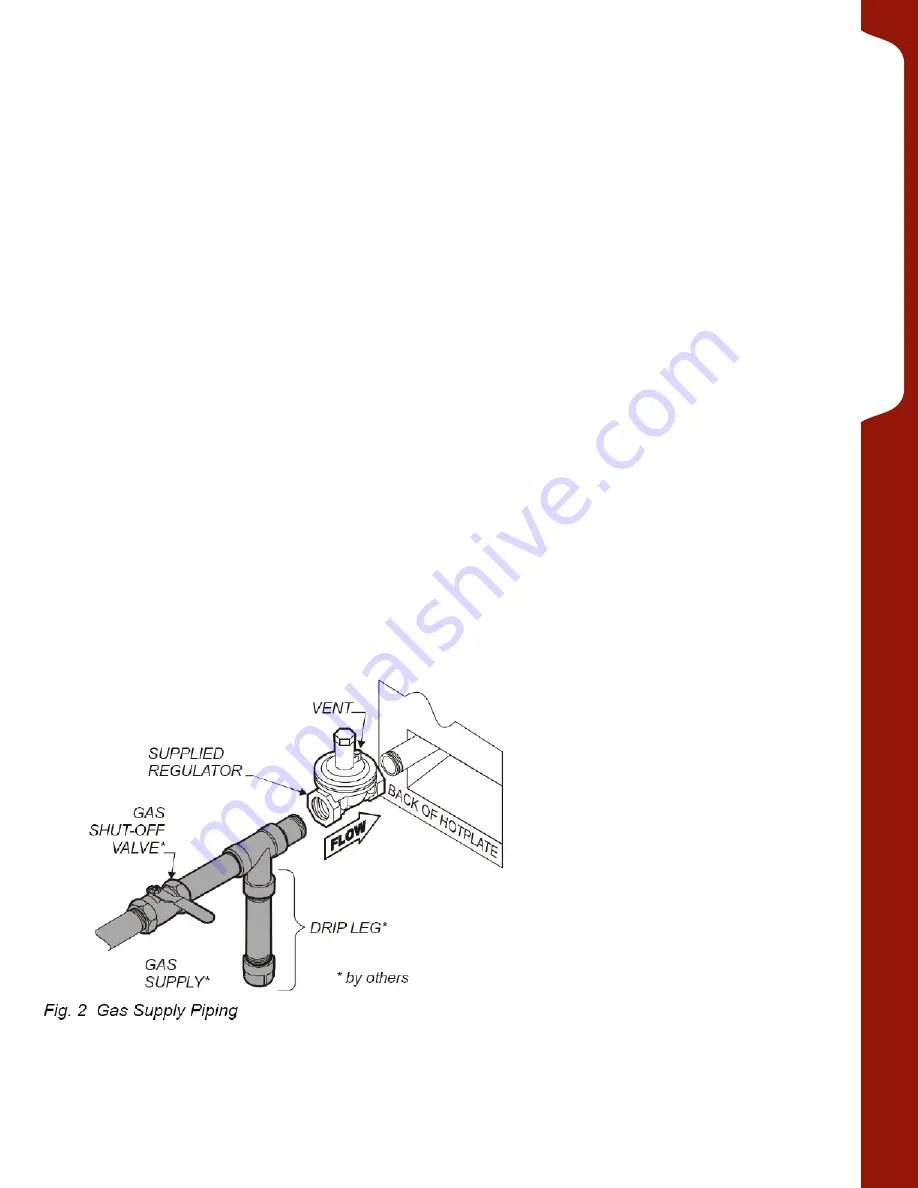

Each gas griddle is supplied with a separate gas pressure regulator,

which must be installed on the manifold pipe protruding from the rear

of the griddle. Ensure that the regulator is installed such that the flow

arrow stamped on the body of the regulator points toward the griddle.

Failure to properly install the supplied regulator will result in an ex-

tremely hazardous condition.

A moisture trap (drip leg) consisting of a tee, 4” nipple pointing down,

and cap must be installed upstream of the gas pressure regulator.

A manual gas shut-off valve may be required by local codes and is,

in any case, strongly recommended. The shut-off valve must be

installed between the gas supply piping and the gas pressure

regulator.

It is the responsibility of the gas piping installer to

identify the code requirement for a shut-off valve.

Shut-off valves, moisture trap and all associated piping must be

supplied by the gas piping installer.

DANGER:

FIRE AND EXPLOSION

HAZARD

NEVER use an open flame to

check for gas leaks. Fire and

explosion may result.

IMPORTANT:

All pipe joints must be checked

for leaks before lighting. Leak

checks should be performed

with a soap and water solution.

WARNING:

FIRE HAZARD

This griddle is supplied with a

gas pressure regulator.

Failure to properly install the

supplied regulator will result in

an extremely hazardous

condition.

Flow arrow stamped on body

of regulator must point toward

the griddle.

Vent hole must point UP.

IMPORTANT:

Verify fuel gas type. If the

available fuel does not match

the nameplate specification,

exchange the griddle for the

correct type.

IMPORTANT:

The appliance and its

individual manual shutoff valve

must be disconnected from

supply system piping during

any pressure testing of that

system at pressures in excess

of 1/2 p.s.i. (3.5 kPa).

Also, the appliance must be

isolated from the gas supply

piping system by closing its

individual manual shutoff valve

during any pressure testing of

the gas supply piping at test

pressures equal to or less than

1/2 p.s.i. (3.5 kPa).

Page 7

Summary of Contents for TSG36-HD

Page 16: ...Page 15...

Page 17: ...Page 16...