å

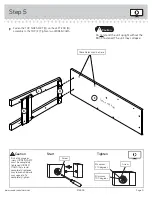

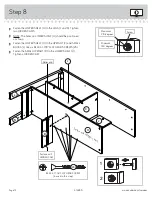

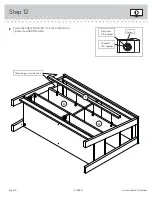

Fasten the TOP SIDE SKIRT (Q) on the LEFT END (B)

assembly to the TOP (E). Tighten two HIDDEN CAMS.

Step 5

416955

www.sauder.com/services

Page 9

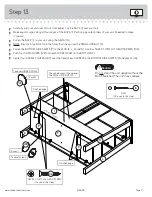

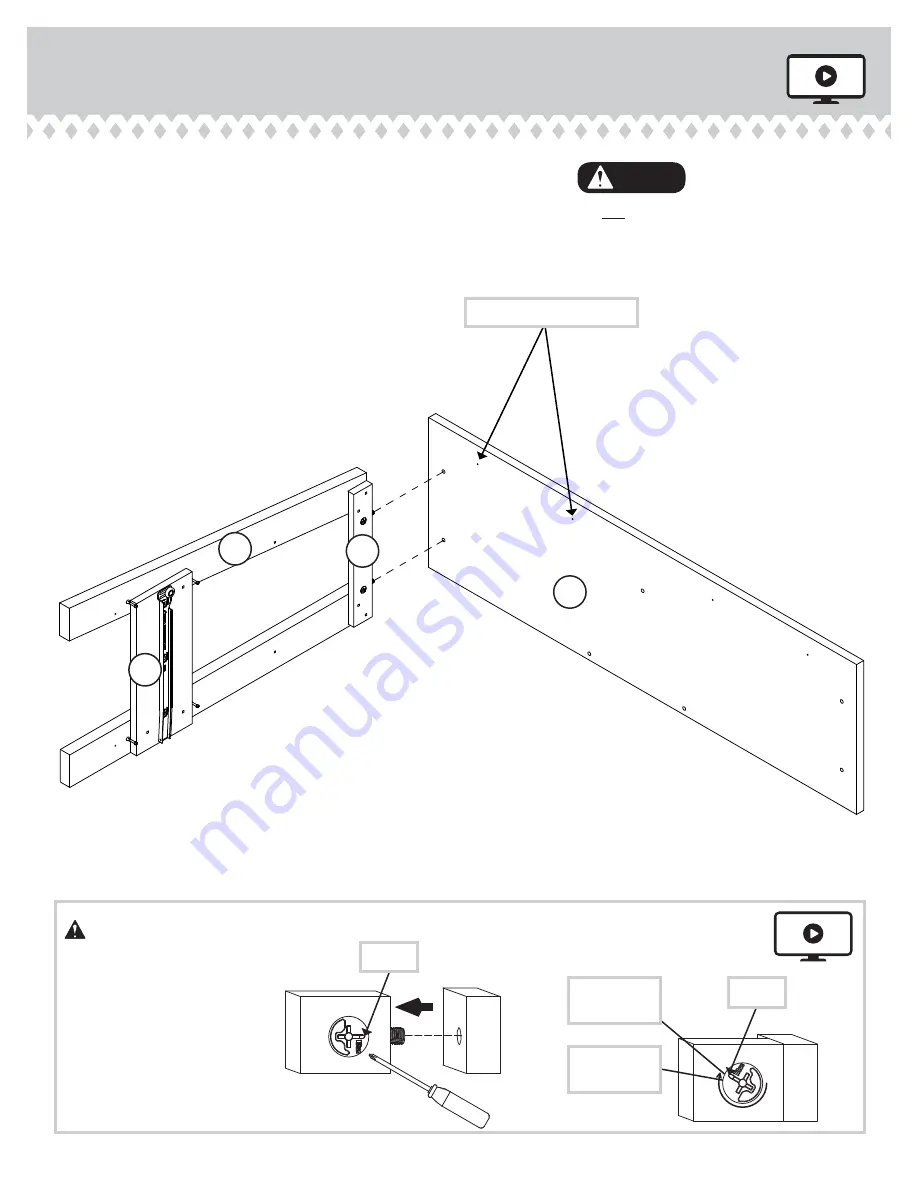

Start

Tighten

Arrow

Minimum

190 degrees

Caution

Risk of damage or

injury. HIDDEN CAMS

must be completely

tightened. HIDDEN

CAMS that are not

completely tightened

may loosen, and parts

may separate. To

completely tighten:

Arrow

Maximum

210 degrees

B

L

Q

E

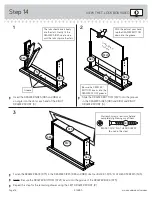

Sur

face with holes

These holes must be here.

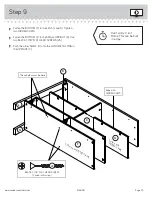

Do not stand the unit upright without the

BACK fastened. The unit may collapse.

Caution