Troubleshooting guide

WP

33L_

BA_K

1_1

2_en_

08.

fm

49

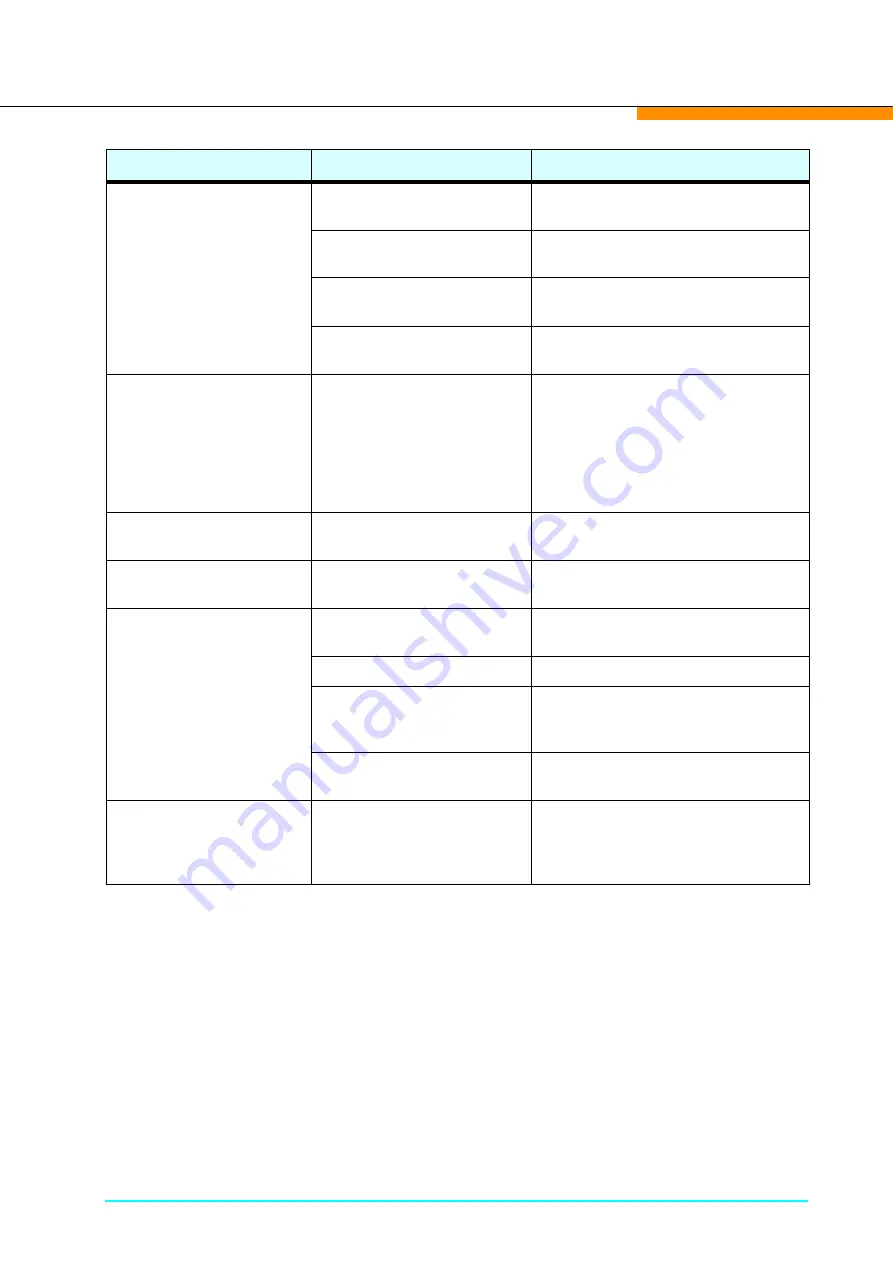

Abnormal compressor

noise.

Connecting rod bearing faulty.

(noise when off-load).

Check connecting rod bearing, replace

if necessary. Check oil supply.

Gudgeon pin bearing faulty.

Check gudgeon pin bearing, replace if

necessary.

Crankshaft bearing faulty.

Check crank shaft bearing, replace if

necessary.

Motor bearing faulty.

Check motor bearing, replace if neces-

sary.

Oil leaking from crankcase.

Gasket or shaft seal faulty.

Screws not tight.

Tighten all screws.

If there is

significant leakage

, check

to see which gasket is faulty, then

replace it.

Minor traces of oil

on the crankcase

or oil drops below the compressor are

harmless. Wipe off with a lint-free rag.

Air leak between cylinder

and valve cover.

Gasket or O-ring of the liner

above the relief groove faulty.

Replace gasket or O-ring.

Oil leak at relief groove of

cylinder flange.

O-ring of the liner beneath the

relief groove faulty.

Replace O-ring.

Water in the oil

Poor ventilation (compressor

is overcooled).

Correct the room ventilation.

Poor drainage.

Check drain lines and drain intervals.

No isolating hose at crankcase

ventilation or isolating hose is

broken.

Replace isolating hose.

Very short compressor run

time.

Extend compressor running time.

Premature failure of valve

plates, valve springs or

valve discs.

Poor drainage.

Check drain lines and drain interval.

Note:

Indentation marks on the valve

plate due to valve impact are normal.

Fault

Probable cause

Remedy

Summary of Contents for WP 33 L

Page 4: ...Zertifikate_en_0 fm Genuine Sauer spare parts certified safety SPECIMEN...

Page 85: ...S a u e r C o m p r e s s o r Type WP 33 L Spare Parts List...

Page 89: ...Spare Parts List WP33L_ET_en_08 fm E 5...

Page 94: ...E 10 WP33L_ET_en_08 fm 060 315 Compressor WP33L 100 21 17 22 1 19 20 11 12 2...

Page 96: ...E 12 WP33L_ET_en_08 fm 060 315 Compressor WP33L 100...

Page 100: ...E 16 WP33L_ET_en_08 fm 061 383 Dipstick 3 1...

Page 102: ...E 18 WP33L_ET_en_08 fm 060 317 Crankshaft 4 5 2 6 3 7 5 4 1...

Page 104: ...E 20 WP33L_ET_en_08 fm 060 280 Connecting rod 1st stage 1 4 7 5 6 50 Nm...

Page 106: ...E 22 WP33L_ET_en_08 fm 060 283 Connecting rod 2nd stage 1 4 7 5 6 50 Nm...

Page 108: ...E 24 WP33L_ET_en_08 fm 034 989 Piston 1st stage 7 3 4 5 6 2 1...

Page 110: ...E 26 WP33L_ET_en_08 fm 060 319 Piston 2nd stage 7 3 4 5 1 6 2...

Page 112: ...E 28 WP33L_ET_en_08 fm 068 628 Cylinder with head and valve 1st stage 3 2 4 5 1...

Page 114: ...E 30 WP33L_ET_en_08 fm 068 615 Cylinder with head and valve 2nd stage 2 3 4 1...

Page 118: ...E 34 WP33L_ET_en_08 fm 060 328 Crankcase vent 3 1 2 5 6 060 328 1st stage...

Page 120: ...E 36 WP33L_ET_en_08 fm 030 915 Safety valve 1st stage 1 3...

Page 122: ...E 38 WP33L_ET_en_08 fm 030 752 Safety valve 2nd stage 1 3...

Page 124: ...E 40 WP33L_ET_en_08 fm 060 440 Air pressure piping 7 8 4 6 2 4 6 9 1 5 10...

Page 126: ...E 42 WP33L_ET_en_08 fm 060 312 Separator 2 7 8 1 4 6 3 8...

Page 128: ...E 44 WP33L_ET_en_08 fm 035 010 Pressure gauge 1 2...

Page 130: ...E 46 WP33L_ET_en_08 fm 060 354 Automatic drainage system 3 1 4 5...

Page 132: ...E 48 WP33L_ET_en_08 fm 060 589 Resilient mounts 3 5 1 4 2 6 4 2 6...

Page 134: ...E 50 WP33L_ET_en_08 fm 065 568 Resilient mounts 3 5 1 4 2 6 4 2 6...

Page 136: ...E 52 WP33L_ET_en_08 fm 061 001 Hose line 1 2...

Page 138: ...E 54 WP33L_ET_en_08 fm Flexible coupling 1 2 3 Compressor Motor...

Page 140: ...E 56 WP33L_ET_en_08 fm Flexible coupling 1 2 3 Compressor Motor...

Page 142: ...E 58 WP33L_ET_en_08 fm...