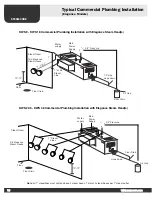

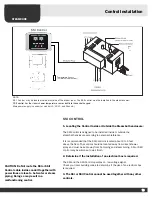

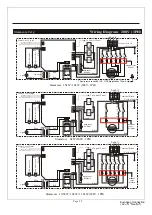

Fig 2

Fig.3

Fig.4

Fig.5

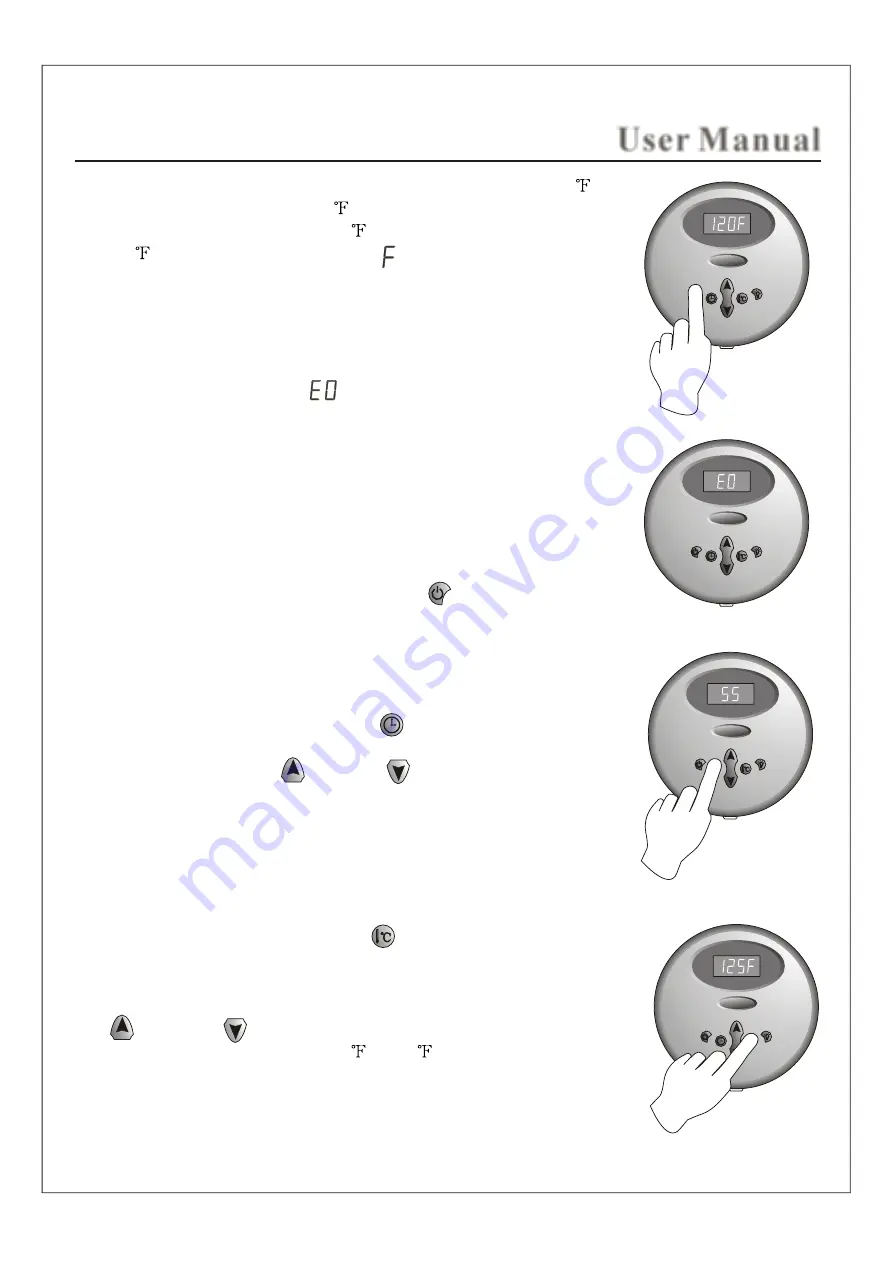

When the actual temperature is smaller than or equal to 32

, the

digital tube will display 32

. When the actual temperature is

smaller than or equal to 140

, the digital tube will display

140

. The last digit displays as the unit of Fahrenheit

temperature. The default start time of steam function is 30

minutes. When the steam is starting, there is a shortage of water,

the heating wire will stop heating and the water input valve will

start automatically. If there is no water tested in 5 seconds or no

water coming to reach the full volume in 15 seconds, the digital

tube will flash to display (as shown in Fig.3) to hint mistake.

If the water is full, the steam function will return to normal.

When the steam function is started, if the temperature of the

environment is higher than the set steam temperature, the

heating wire will stop heating, the digital tube will flash to

d i s p l a y t h e c u r r e n t e n v i r o n m e n t t e m p e r a t u r e ; w h e n t h e

e n v i r o n m e n t t e m p e r a t u r e i s l o w e r t h a n t h e s e t s t e a m

temperature, the heating wire will restore heating, the digital

tube will display normally current environment temperature.

When the system is started, press button or when the

steam function time is due, the system will be shut. 10 minutes

after the system is shut off, the drainage function will be started

automatically for 5 minutes.

Time setting

When the machine is started, press button and the digital tube

will display the remaining time of current steam function (as

shown in Fig.4), press button or button to adjust the

remaining time. The adjustment range is 1-99 minutes with 1

minute as one level. If there is no adjustment in 5 seconds, the

system will quit the time setting function. The digital tube will

restore to display current environment temperature.

Temperature setting

Whenthemachine is started,press

button and the digital tube

will display the set steam time (as shown in Fig.5), at the same

time the temperature unit will flash to hint that the machine has

entered the steam temperature setting function. At this time, press

button or

button to adjust the temperature parameter.

The adjustment range is 50-130

with 1

as one level. If there is

no adjustment in 5 seconds, the system will quit the temperature

setting function. The digital tube will restore to display current

environment temperature.

23

User Manual

Summary of Contents for KWS 10.5

Page 25: ...s ight s Page 25...

Page 26: ...Page 26...