WARNING! SEVERAL POWER SUPPLY. CHECK THAT THERE

IS NO CHARGE IN THE MACHINE BEFORE DOING ANY

MAINTENANCE WORK!

Checking and fault-finding.

In the e vent of faulty operation, f irst check the f ollowing:

• are the contr ol panel and st eam generat or wired up in

accor dance with the wiring diagram?

• is the st eam generat or correctly installed in accor dance

with these instructions?

• does the drainage pipe slope do wn pr operly t owards the

drain?

• is the f ilter clogged? The f ilter is locat ed at the point where

incoming w ater is fed into the generat or. T o clean the f ilter,

disconnect the f eed pipe, rinse it free fr om par ticles of

calcium carbonat e and o ther deposits.

• are there an y sharp bends in the st eam pipe? (the

minimum permitt ed radius of bends is 50 mm, 2")

• If there is a tap on the w ater supply t o the st eam generat or,

make sure this is no t closed.

Checklist

with alternative causes of pr oblems and suggest ed actions.

L

Lo

ou

ud

d n

no

oiisse

ess iin

n tth

he

e ffe

ee

ed

d p

piip

pe

ess w

wh

he

en

n tth

he

e

sso

olle

en

no

oiid

d vva

allvve

e o

op

pe

en

nss o

orr ccllo

osse

ess..

Cause: The st eam generat or feed pipes are no t sufficiently

secure.

Solution: Fix the pipes securely t o the w all with pipe clips.

Cause: “Recoil” problems in the f eed pipe (Pipe hammer).

Solution: R eplace a metre-long length of piping nearest the

steam generat or with fle xible piping, f or exam ple, reinf orced

rubber hosing, which will withstand the

pressure.

T

Th

he

e sstte

ea

am

m rro

oo

om

m rre

eq

qu

uiirre

ess a

an

n a

ab

bn

no

orrm

ma

allllyy llo

on

ng

g ttiim

me

e tto

o h

he

ea

att u

up

p..

Cause: The generat or is no t powerful enough. See table.

Solution: R eplace the st eam generat or with one with a higher

heat output.

Cause: Ex cessiv e v entilation in the st eam r oom.

Solution: R educe the v entilation to evacuate 10–20 cubic

metres (1 3–26 cub. yd) of air per per son per hour .

Cause: Blo wn fuse in the main fuse bo x.

Solution: R eplace the fuse.

Cause: The ambient t emperature is lo wer than 15°C (59 °F).

Solution: Increase the ambient t emperature or replace the

steam generat or with a more po werful one.

Cause: Heating element is br oken.

Solution: R eplace element.

Cause: The thermostat sensor is t oo close t o the st eam jet.

Solution: Mo ve the sensor or change the direction of the

steam jet.

H

Ho

ott w

wa

atte

err rru

un

nss ffrro

om

m tth

he

e sstte

ea

am

m h

he

ea

ad

d.. L

Liittttlle

e

o

orr n

no

o sstte

ea

am

m iin

n tth

he

e sstte

ea

am

m rro

oo

om

m..

Cause: The solenoid v alve for incoming w ater has stuck,

due to accumulat ed deposits of f oreign bodies or an

electrical malfunction.

Solution: R emove the v alve and clean it, or rectify the

electrical malfunction.

Cause: The solenoid v alve is br oken.

Solution: R eplace the v alve.

Cause: Malfunction in the cir cuit boar d.

Solution: R eplace the cir cuit boar d.

E

Errrra

attiicc sstte

ea

am

m p

prro

od

du

uccttiio

on

n rriig

gh

htt ffrro

om

m tth

he

e sstta

arrtt..

Cause: The thermostat sensor is wr ongly placed in relation t o

the steam jet.

Solution: Mo ve the sensor or alt er the direction of the st eam

jet.

Cause: Calcium carbonat e or o ther foreign bodies in the f ilter.

Solution: R emove and clean the f ilter.

N

Ne

eiitth

he

err sstte

ea

am

m n

no

orr h

he

ea

att iiss g

ge

en

ne

erra

atte

ed

d iin

n tth

he

e

sstte

ea

am

m rro

oo

om

m..

Cause: Blo wn fuse in the mains fuse bo x.

Solution: R eplace the fuse.

Cause: The w ater is no t reaching the st eam generat or.

Solution: Open the tap(s) connect ed to the piping t o allo w

incoming w ater to flow into the st eam generat or.

Cause: The contr ol panel is incorrectly set.

Solution: Check the time and t emperature on the contr ol

panel.

Cause: The f ilter is clogged.

Solution: R emove the f ilter which is placed in the connection

for incoming w ater. Clean of f any metal f ilings or o ther foreign

bodies.

Cause: The solenoid v alve for w ater supply has stuck .

Solution: R emove the solenoid v alve and clean of f any metal

filings or o ther foreign bodies.

Cause: Ex cessiv e calcium carbonat e deposits in the st eam

generat or’s w ater reser voir.

Solution: R eplace the entire w ater reser voir, including heating

elements and electr odes.

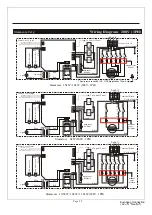

Cause: The st eam generat or is wired up f or the wr ong v oltage.

Solution: Check the v oltage and the connection t o the

generat or – see diagram.

Cause: The t emperature limit contr ol has been triggered,

Solution: Check and remedy an y faults on the st eam pipe,

such as a block age due t o se veral sharp bends, w ater pock ets

or greatly reduced int ernal diamet er. The tank ma y also be

clogged with limescale.

Cause: Fla w in the cir cuit boar d, contr ol panel or magnetic

contactor.

Solution: R eplace the f aulty com ponent.

T

Te

em

mp

pe

erra

attu

urre

e ccu

utt-o

offff iiss a

accttiivva

atte

ed

d..

Cause: The st eam pipe is block ed.

Solution: R emove the block age.

Cause: The int ernal diamet er of the st eam pipe is

considerably reduced.

Solution: R eplace the pipe or the pipe joint which is causing

the reduction (Int ernal diamet er must be at least 12 mm, ½").

Cause: Sharp bends ( “elbows ”) along the st eam pipe.

Solution: Get rid of “elbows ” in the pipe. Bends are t o be

gently r ounded (minimum radius 50 mm, 2").

Cause: Large w ater pock et some where along the st eam pipe.

Solution: A djust the st eam pipe t o eliminate the w ater pock et.

Cause: Ex cessiv e calcium carbonat e deposits in the st eam

generat or’s reser voir.

Solution: R eplace the entire reser voir, including elements and

electrodes.

T

Th

he

e sstte

ea

am

m rro

oo

om

m m

ma

aiin

ntta

aiin

nss tth

he

e d

de

essiirre

ed

d tte

em

mp

pe

erra

attu

urre

e

((4

40

0–

–5

50

0°

°C

C,, 1

10

05

5–

–1

12

22

2°

°F

F)),, b

bu

utt n

no

o sstte

ea

am

m iiss p

prro

od

du

ucce

ed

d..

Cause: Insuf ficient v entilation in the st eam r oom.

Solution: Increase v entilation. The v entilation is insuf ficient if

less than 1 0–20 cubic metres (1 3–28 cub. yd) of air per

person per hour is e vacuated via the outlet v ent. This

situation ma y occur if the outlet v ent is no t connect ed to

some f orm of mechanical e xtractor fan – or if the v entilation

duct is block ed by a w ater pock et. (Commer cial applications)

Cause: The air coming int o the st eam r oom is t oo w arm.

Solution: R educe the intak e air temperature to 35°C (95 °F).

Cause: The ambient t emperature is higher than 35 °C (95 °F).

Solution: Ensure that the ambient t emperature does no t

exceed 35°C (95 °F).

Cause: The thermomet er is faulty or wr ongly placed.

Solution: The thermomet er should be placed appr oximately

(72") abo ve floor le vel and as f ar away from the st eam jet as

possible.

H

Ho

ott w

wa

atte

err cco

om

me

ess o

ou

utt o

off tth

he

e sstte

ea

am

m h

he

ea

ad

d iin

n

ssp

pu

urrttss o

orr iin

n a

a sslliig

gh

htt,, e

evve

en

n ffllo

ow

w m

miixxe

ed

d w

wiitth

h

sstte

ea

am

m..

Cause: Small w ater pock et along the st eam pipe.

Solution: Eliminat e the w ater pock et.

Cause: The st eam pipe is uninsulat ed along t oo great a

por tion of its length.

Solution: Insulat e the st eam pipe. A continuous trickle of ho t

water from the st eam generat or’s drainage pipe.

Cause: The solenoid v alve for automatic em ptying has stuck .

Solution: Switch of f the steam generat or. See what happens

again af ter an 80-minut e pause. If the f ault per sists, remo ve

the solenoid v alve for the aut omatic em ptying function and

clean it.

3 3

3

www.saunacore.com

Trouble Shooting

STEAMCORE

32

Summary of Contents for KWS 10.5

Page 25: ...s ight s Page 25...

Page 26: ...Page 26...