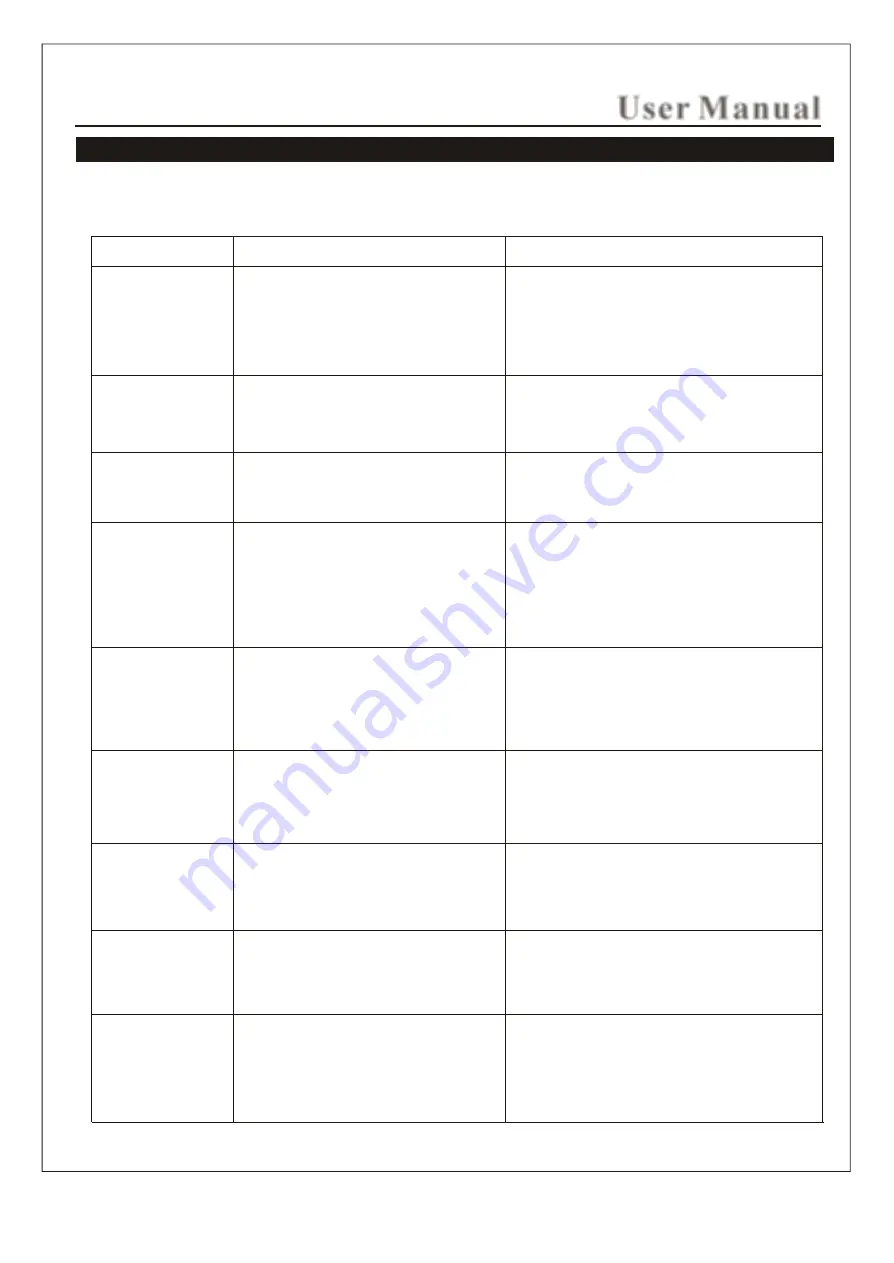

Common

trouble shooting methods

To facilitate your use and maintenance of sauna room, the following common

trouble shooting methods are listed for

refere

n

ce

.

Troubles

Causes of troubles

Trouble-shooting methods

The machine

does not start

when

electrified

1.The fuse is burned.

2.The wire connection terminal

becomes loose.

3.Not good contact in the

connection wire between the

controller and the steam engine.

1.Change the fuse (on the shell 0.8A/

250V)

2.Plug tight the wire connection terminal

3.Make sure the steam engine and the

controller come into good contact

Electricity

leakage switch

breaks

automatically

1.The wire connector is dampened

or damaged.

2.The heating tube breaks

1.Check whether the wire connector is

dampened or damaged, and dry with

dryer if dampened.

2.

Change a heating tube.

When the machine is

started, hot water

comes out with little

or no steam

1. The water drainage valve is broken.

1. Change a water drainage valve.

The display screen

on the control panel

does not display

1.The power wire is not connected well

or not in good contact. The connection

plug between the control panel and the

electrically-controlled box becomes

loose.

2.Trouble with plugboard.

1.Check whether the connection plug between

the control panel and the electrically-

controlled box has become loose, and

whether the power circuitry has good contact.

2.Change a plugboard.

Water leakage

1.The water pipe connector becomes

loose or the pipe breaks

2.Water leakage in the water input

valve or the waterdrainage valve

1.Tighten the loose connector, and change the

broken pipe.

2.Change the water input valve or the water

drainage valve.

No steam when

starting the

machine

1.No electricity.

2.No water.

3.The set temperature is too low

4.Troublewithwire.

1.Check the power supply

2.Check the water input pipe and water input

valve

3.Reset the temperature

4.Contact the distributor

The steam does not

come out, the water

sounds in the

machine

1. The steam pipe is jammed.

1. Cut power supply to check whether the

steam pipe is smooth.

The light can not

be turned on

1. The fuse is burned.

2. The light is broken

3. The wire is broken

4. The plug does not have good contact

1.Change the fuse (on the shell 1A/250V)

2. Change a light bulb.

3. Change wire.

4. Make the contact good.

The display box

displays normally

with no steam

input

1.Too much pressure inside the steam

engine, so the system breaks for heat

protection.

2.Wire is broken for heat protection.

1.Check the steam transport pipe and restore

automatically after heat protection

becomes cool.

2.Check the heat protection wire to make sure

the connection is good.

33

User Manual

Technical Hotline 905-951-6662

Summary of Contents for KWS 10.5

Page 25: ...s ight s Page 25...

Page 26: ...Page 26...