22

2000225294A

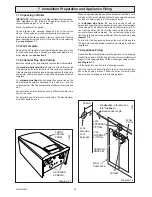

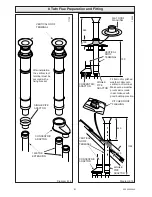

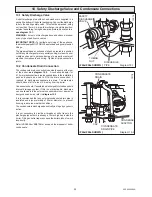

Diagram 7.1

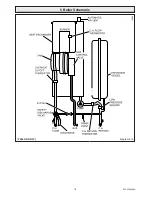

7 Installation Preparation and Appliance Fixing

7.1 Unpacking of Boiler

IMPORTANT:

With regards to the Manual Handling Operations,

1992 Regulations, the following lift operation exceeds the

recommended weight for a one man lift.

Stand the boiler carton upright.

Cut and remove the securing straps and lift off the carton

sleeve. Place aside any loose components until required.

Carefully lay the boiler on its back, remove the two front casing

panel securing screws and lift off the panel from two retaining

lugs,

see diagram 7.1

.

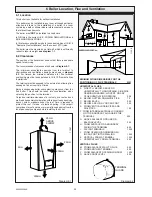

7.2 Wall Template

Remove the wall template from the installation pack and place

in the desired position on a flat wall, giving due consideration to

boiler clearances,

see section 6

.

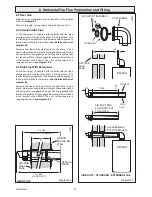

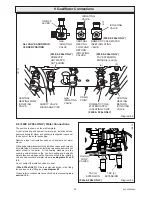

7.3 Horizontal Flue Hole Cutting

Mark the centre of the flue hole and remove the wall template.

The

standard horizontal flue

is designed with an internal fall

of 35mm/metre towards the boiler for disposal of condensate.

If the standard flue length alone is being used then the flue hole

of diameter 105mm can be cut in the position marked on the wall

template.

For

standard side flues

the horizontal flue centre line on the

wall template should be extended to the side wall, and the

vertical centre of the flue hole marked at 206mm from the back

wall.

For installations with external access, a 105mm diameter core

drill can be used.

For installations with internal access only a 125mm diameter

core drill should be used.

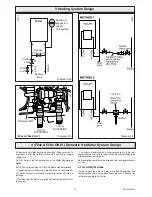

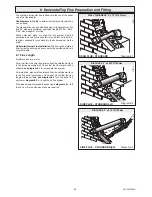

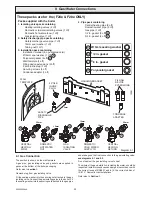

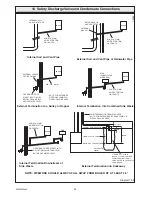

Diagram 7.2

When using extension pipes with the horizontal rear flue, a core

drill size of 125mm should be used to allow the extension pieces

to slope at 35mm/metre (2.5

o

) towards the boiler.

For

extended side flues

, the flue hole centre should be

determined by extending the dashed inclined line on the template

to the side wall. This dashed line is drawn at 35mm/metre (2.5

o

)

rise from the boiler. Where this line reaches the side wall, a

horizontal line should be marked. The vertical centre line of the

flue should then be marked at 206mm from the back wall,

see

diagram 7.2.

To allow for the flue passing through the wall at this angle a

125mm hole should be drilled irrespective of internal or external

installation.

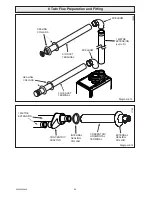

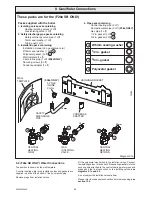

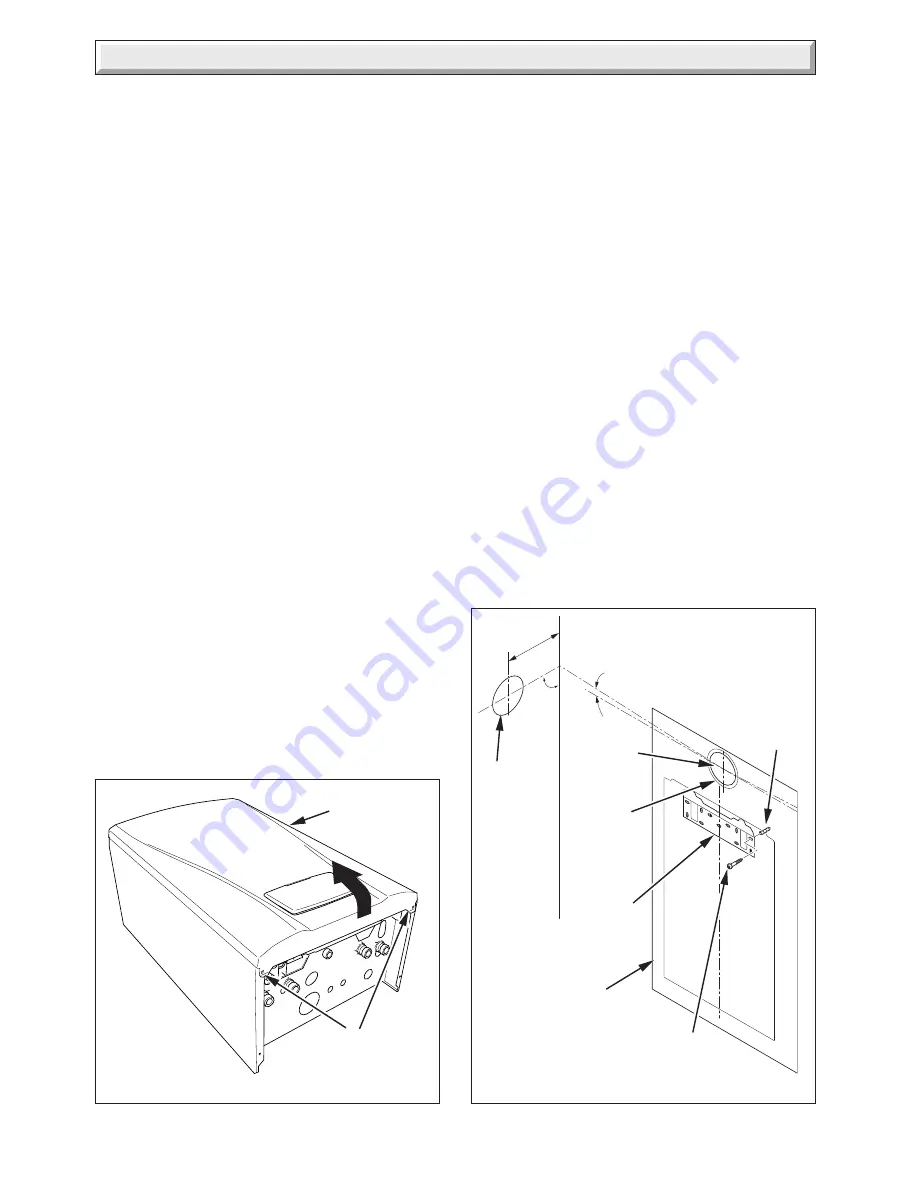

7.4 Appliance Fixing

Reposition the wall template mark the position of the hanging

bracket fixing holes. Drill the fixing holes and insert suitable wall

plugs. Fix the hanging bracket to the wall using suitable screws,

see diagram 7.2.

Lift the boiler into position in the following manner.

Lean the top of the boiler slightly to the wall and position just

above the hanging bracket. Allow the boiler to slowly move

downwards until engaged in the hanging bracket.

FRONT

CASING

PANEL

SECURING

SCREWS

HANGING

BRACKET

WALL

TEMPLATE

SCREW

WALL

PLUG

206mm

ø105

Standard

Horizontal -

Standard flue

2.5

°

Inclined -

Extended flue length

90

°

11902

ø105

EXTERNAL

FITTING

ø125

INTERNAL

FITTING

12182

ø125

Extended

Summary of Contents for EnviroPlus F24e

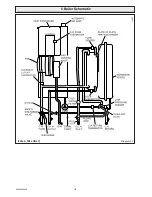

Page 18: ...18 2000225294A Diagram 5 1 11907 5 Boiler Schematic F24e F28e ONLY ...

Page 19: ...19 2000225294A 5 Boiler Schematic Diagram 5 1a 12248 BYPASS F28e SB ONLY ...

Page 49: ...49 2000225294A 14 Fault Finding 12410 Diagram 14 4 ...

Page 51: ...51 2000225294A 15 Wiring Diagram Diagram 15 1a 12240 F28e SB ONLY ...