41

2000225294A

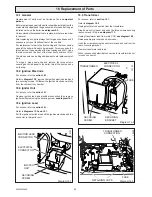

13 Servicing

13.1 General

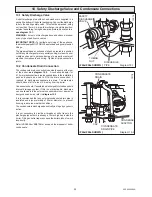

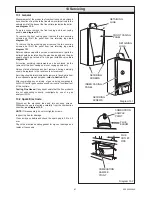

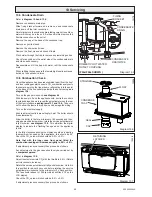

Measurement of the products of combustion can be achieved

by connection of a probe to the flue elbow or alternatively to the

sample point at the base of the flue outlet pipe inside the boiler

,

see diagram 13.2.

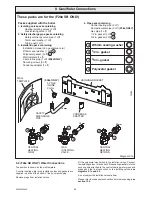

To gain access remove the front casing and inner casing

panels,

see diagram 13.1.

To remove the front casing panel remove the two securing

screws and lift off the panel from two retaining lugs,

see

diagram 13.1.

To remove the inner casing panel remove the two securing

screws and lift off the panel from two retaining lugs,

see

diagram 13.1.

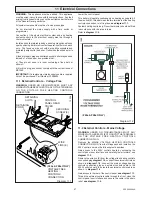

Before commencing with a service or replacement of parts the

boiler should be isolated from the electrical supply and the gas

supply should be turned off at the gas isolation valve,

see

diagram 9.2.

All routine servicing requirements can be achieved by the

removal of the front casing and inner casing panels only.

Unless stated otherwise any part removed during servicing

should be replaced in the reverse order to removal.

Servicing should always include the removal of any debris from

the condensate pipe and siphon,

refer to Section 13.5.

After completing any servicing of gas carrying components,

ALWAYS test for gas soundness and carry out a functional test

of the controls.

Testing Flue Gases:

If any doubt exists that the flue products

are not exhausting correctly, investigate by use of a gas

analyser (FGA).

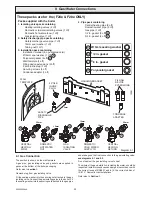

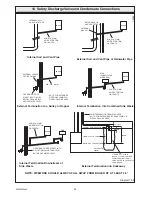

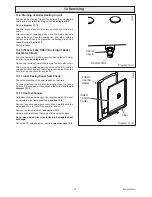

13.2 Spark Electrode

Disconnect the electrode lead and two securing screws.

Withdraw the spark electrode carefully from the combustion

chamber,

see diagram 13.3.

NOTE:

On reassembly do not overtighten screws.

Inspect the tips for damage.

Clean away any debris and check the spark gap is 3.5 to 4.5

mm.

Check the electrode sealing gasket for signs of damage and

replace if necessary.

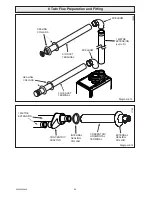

Diagram 13.2

FLUE

OUTLET

PIPE

COMBUSTION

SAMPLE

POINT

FLUE

ELBOW

COMBUSTION

SAMPLE

POINT

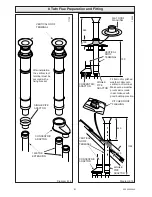

Diagram 13.1

RETAINING

LUGS

FRONT CASING

PANEL

SECURING

SCREWS

INNER CASING

PANEL

RETAINING

LUGS

SECURING

SCREWS

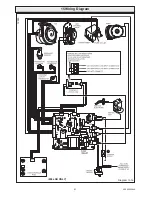

Summary of Contents for EnviroPlus F24e

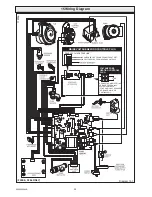

Page 18: ...18 2000225294A Diagram 5 1 11907 5 Boiler Schematic F24e F28e ONLY ...

Page 19: ...19 2000225294A 5 Boiler Schematic Diagram 5 1a 12248 BYPASS F28e SB ONLY ...

Page 49: ...49 2000225294A 14 Fault Finding 12410 Diagram 14 4 ...

Page 51: ...51 2000225294A 15 Wiring Diagram Diagram 15 1a 12240 F28e SB ONLY ...