8

2000225294A

IMPORTANT NOTE:

Please be advised that the 'Benchmark' logbook should be

completed by the engineer on completion of commissioning or

servicing.

All CORGI Registered Installers carry a CORGI ID card, and

have a registration number. Both should be recorded in your

benchmark Logbook. You can check your installer is CORGI

registered by calling CORGI direct on: 01256 372300.

Water Treatment

In the case of an existing installation, it is

ESSENTIAL

that prior

to installing the new boiler the system is thoroughly flushed.

For optimum performance after installation of a new system, the

boiler and its associated central heating system should also be

flushed. Flushing should be carried out in accordance with

BS7593: 1992 using a cleanser such as Sentinel X300 or X400,

Fernox Superfloc or Salamander corrosion guard cleaner.

For long-term corrosion protection, after flushing, an inhibitor

suitable for stainless steel exchangers should be used, refer to

the current issue of BS 5449 and BS 7593 on the use of

inhibitors in central heating systems. Examples are Sentinel

X100 Fernox or Salamander corrosion guard inhibitor.

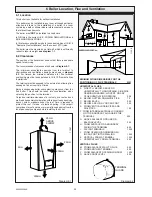

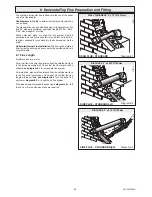

Compartment Installations

If the boiler is fitted into a compartment it does not require

ventilation openings.

Do not use the compartment for storage.

The boiler is not suitable for cupboard installation.

User Instructions - General Information

Clearances

If fixtures are positioned close to the boiler, space must be

left as shown in

section 2

. Enough space must also be left in

front of the boiler to allow for servicing.

Condensate Drain

The condensate drain,

see section 10.2

, must not be modified

or blocked.

Pluming from flue terminal

Like all condensing boilers this appliance will produce a plume

of condensation from the flue terminal in cool weather. This is

due to the high efficiency and hence low flue gas temperature

of the boiler. It is normal and not a fault indication.

Electrical and Gas Supplies

If the mains electricity and gas are to be turned off for any

long periods during severe weather, it is recommended that

the whole system, including the boiler, should be drained to

avoid the risk of freezing. Make sure that, if fitted, the

immersion heater in the cylinder is switched off.

If you have a sealed water system contact your installation/

servicing company as draining, refilling and pressurising MUST

be carried out by a

competent person

.

User Instructions - Maintenance and Servicing

Draining and filling

Caution: The boiler is installed as part of a sealed system which

must only be drained and filled by a

competent person

.

If the boiler is to be out of use for any long periods during severe

weather conditions, it is recommended that the whole system,

including the boiler, be drained to avoid the risk of freezing.

If in doubt, consult your installation/servicing company.

Cleaning

WARNING:

This appliance contains metal parts (components)

and care should be taken when handling and cleaning with

particular regard to edges of sheet metal parts to avoid any

possibility of personal injury.

The boiler casing can be cleaned using a mild liquid detergent

with a damp cloth, then a dry cloth to polish.

Do not use any form of abrasive or solvent cleaner as you may

damage the paintwork.

Do not use abrasive or solvent cleaners.

Maintenance and Servicing

To ensure the continued efficient and safe operation of the

appliance it is recommended that it is checked and serviced as

necessary at regular intervals. The frequency of servicing will

depend upon the particular installation conditions and usage,

refer to guarantee registration on the front cover of this literature.

If this appliance is installed in a rented property there is a duty

of care imposed on the owner of the property by the current

issue of the Gas Safety (Installation and Use) Regulations,

Section 35.

Servicing/maintenance should be carried out by a

competent

person

in accordance with the rules in force in the countries of

destination.

To obtain service, please call your installer or Saunier Duval

service organisation using the telephone number on the front

cover of this literature.

Spare Parts

REMEMBER, When replacing a part on this appliance, use only

spare parts that you can be assured conform to the safety and

performance specification that we require. Do not use

reconditioned or copy parts that have not been clearly authorised

by Saunier Duval.

If a part is required contact Saunier Duval Service using the

telephone number on the inside front cover of this booklet.

Please quote the name of the appliance, this infomation will be

on the name badge on the front of the appliance.

If in doubt seek advice from the local gas company or Saunier

Duval service organisation using the telephone number on the

inside front cover of this booklet.

Summary of Contents for EnviroPlus F24e

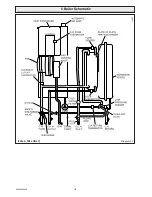

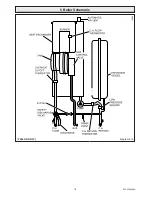

Page 18: ...18 2000225294A Diagram 5 1 11907 5 Boiler Schematic F24e F28e ONLY ...

Page 19: ...19 2000225294A 5 Boiler Schematic Diagram 5 1a 12248 BYPASS F28e SB ONLY ...

Page 49: ...49 2000225294A 14 Fault Finding 12410 Diagram 14 4 ...

Page 51: ...51 2000225294A 15 Wiring Diagram Diagram 15 1a 12240 F28e SB ONLY ...