24

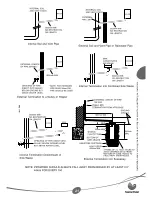

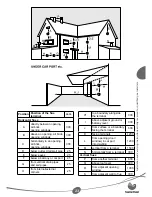

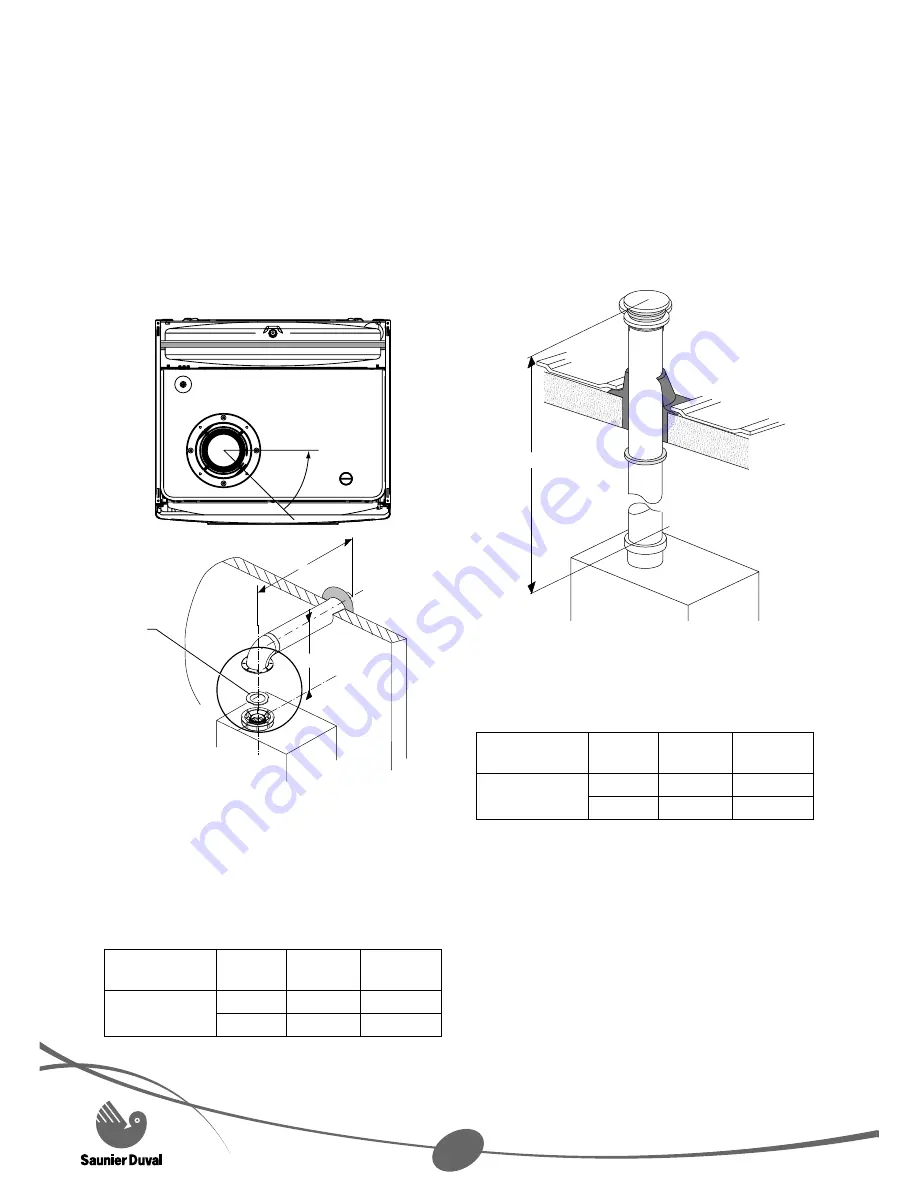

H*: This dimension comply with the

building regulations, but it may need to

be increased to avoid wall staining and

nusance from pluming depending on site

conditions.

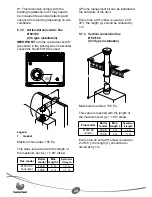

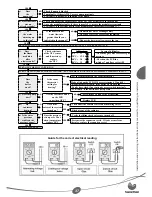

5.7.2 Horizontal

concentric

fl ue

Ø 60/100

(C13 type installation)

IMPORTANT:

turn the coaxial socket 45°

(as shown in the picture) when horizontal

concentric fl ue Ø 60/100 is used.

1035_R01

45°

1

L

72

1034_R00

Legend

1 Gasket

Maximum fl ue index: 150 Pa

This value is reached with the length of

the maximum duct (L) + 1 90° elbow.

Flue model

Boiler

model

Max.

length L

Restrictor

if length

Ø 60/100

horizontal

F24 E

4 m

< 2 m

F30 E

3 m

< 1 m

A Plume mangement kit can be installed at

the extremity of the duct.

Every time a 90° elbow is used (or 2 off

45°), the length (L) should be reduced by

1 m.

5.7.3 Vertical

concentric

fl ue

Ø 60/100

(C33 type installation)

L

Maximum fl ue index: 150 Pa

This value is reached with the length of

the maximum duct (L) + 1 90° elbow.

Flue model

Boiler

model

Max.

length L

Restrictor

if length

Ø 60/100

vertical

F24 E

5 m

< 2 m

F30 E

4 m

< 1 m

Every time an extra 90° elbow is used (or

2 off 45°), the length (L) should be re-

duced at by 1 m.