11

SAFETY DEVICES

Flue safety device

If an obstruction, even

partial, of the flue oc-

curs, for any reason

whatsoever, the built in

flue safety device will

turn the boiler OFFand

the warning LED on the

Sec 055

In case of loss of water in

the system

CAUTION. The boiler is in-

stalled as part of a sealed

system which must only be

drained and filled by a

competent person.

If the pressure shown on

the pressure gauge,

see

diagram 16

, is less than 1 bar, the system must be

filled up immediately. Call your Installer/Service

Provider.

Overheat safety

In the event of a problem, the overheat safety

device cause safety shutdown of the boiler. If this

happens, call your Installer/Service Provider.

Frost protection

The

THEMA C 23

boiler

has a built in frost pro-

tection device that pro-

tects the boiler from

freezing. If the boiler is to

be left and there is a risk

of frost, ensure that the

gas and electrical sup-

Diagram 17

plies are left connected and that the Summer/Win-

ter switch is in the 'Summer' position.

The frost protection device will light the boiler when

the temperature of the boiler water falls below 6

°

C.

When the temperature reaches 16

°

C, the boiler

stops.

Note:

This device works irrespective of any room

thermostat setting and only protects the boiler.

Important notice

: Under no circumstances must the

flue safety device be bypassed or removed. Any

repairs on the flue safety device must be carried

out by a qualified engineer using genuine replace-

ment parts only.

Air in the heating system

Persistent air in the heating system may indicate

leaks in the system or corrosion taking place. Call

your Installer/Service Provider.

Gas leak or fault

If a gas leak or fault exists or is suspected, turn the

boiler off and consult the local gas undertaking or

your Installer/Service Provider.

In case of power supply failure

The boiler no longer operates.

As soon as power supply is restored, the boiler will

be automatically restarted.

Important notice:

A central heating system cannot

operate satisfactorily unless it is properly filled with

water and unless the air initially contained in the

piping systems has been properly bled off. If these

conditions are not satisfied, air noise will occur

within the system.

Sec 056

SETTINGS

Bypass

The built-in bypass must be adjusted according to

the requirements of the system. Refer to the flow

rate/pressure curve (

diagram 3

). The boiler is sup-

plied with the bypass open half a turn. It is adjusted

by turning the bypass screw,

see diagram 18

. Turn

the screw clockwise to close the bypass.

When using thermostatic radiator valves (TRV's), it

is advisable to fit a separate, adjustable bypass of

15 mm minimum diameter between the flow and

return connections of the heating circuit. Any by-

pass must be fitted before system controls.

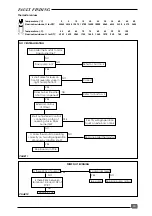

Pump operation in heating mode

The PCB can be set to operate the pump in two

ways,

see diagram 19.

Position D: Intermittent pump operation.

With the jumper set to position 'D', the pump will

operate during operation of the room thermostat.

Position C: Continuous pump operation.

With the jumper set to position 'C', the pump will

operate continuously.

Reg 013

Reg 004

Diagram 15

boiler control panel will light. If this occurs, contact

your Installer/Service Provider.

Diagram 16

Diagram 18

Diagram 19