8

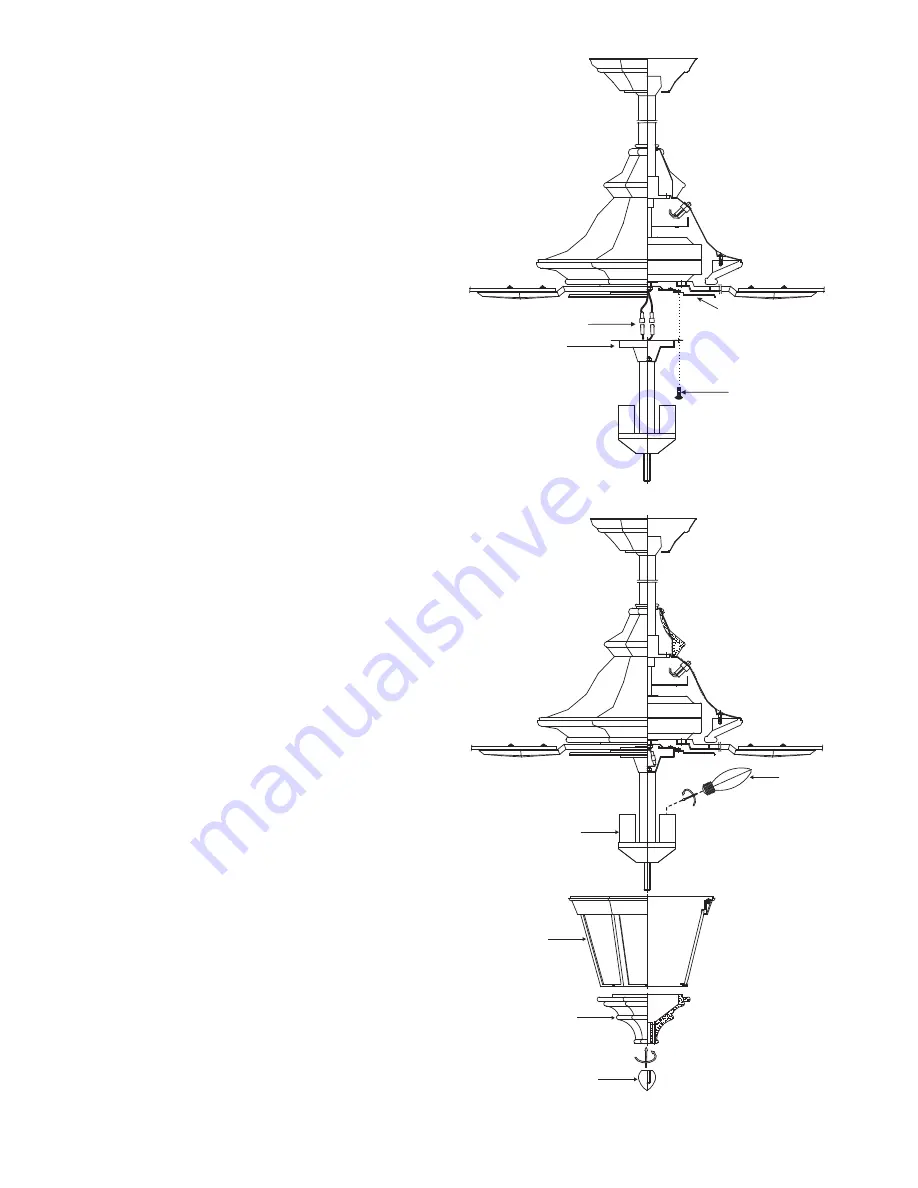

Figure 16

Figure 17

Mounting plate

Light kit

Connection plugs

Screws

Light kit

Bulbs

Glass shade

Decorative cover

Decorative nut

11. INSTALLING THE LIGHT

KIT

NOTE:

Before starting installation,

disconnect the power by turning off the

circuit breaker or removing the fuse at

fuse box. Turning power off using the fan

switch is not sufficient to prevent electric

shock.

Step 1.

Remove the 1 of 3 screws from the

mounting plate and keep it for future use.

Loosen the other 2 screws (Do not

remove)

Step 2.

Raise and hold the light kit close

to the mounting plate and proceed to do

the wire connections. Connect the white

wire connectors from the light kit and fan,

follow the same procedure with the black

wire connectors. (Fig. 16)

S

tep 3.

Tuck connections neatly into

mounting plate, Place the light plate key

holes over the 2 screws previously

loosened from the mounting ring, turn

light kit until it locks in place at the narrow

section of the key holes. secure by

tightening the 2 screws previously

loosened and the one previously removed.

(Fig. 16).

12. INSTALLING THE GLASS

SHADE & LIGHT BULBS

1. Install 3 x 40w candelabra bulbs

(included). (Fig. 17)

2. Place the glass shade and glass frame

to the light kit with the decorative

cover and decorative nut provided.

DO

NOT OVER TIGHTEN.

(Fig. 17)

3. Restore power and your light kit is

ready for operation.