●

FOR REFRIGERATOR USERS

・ Failing to service properly may result in poor reliability of the refrigerator.

・ Read this booklet carefully and perform servicing with great care.

・

●

FOR SAFETY OF YOURSELF

・

●

SAFETY SYMBOLS

・ The following warning labels in this booklet indicate precautions for service work.

Comply with what each symbol indicates whenever it appears.

●

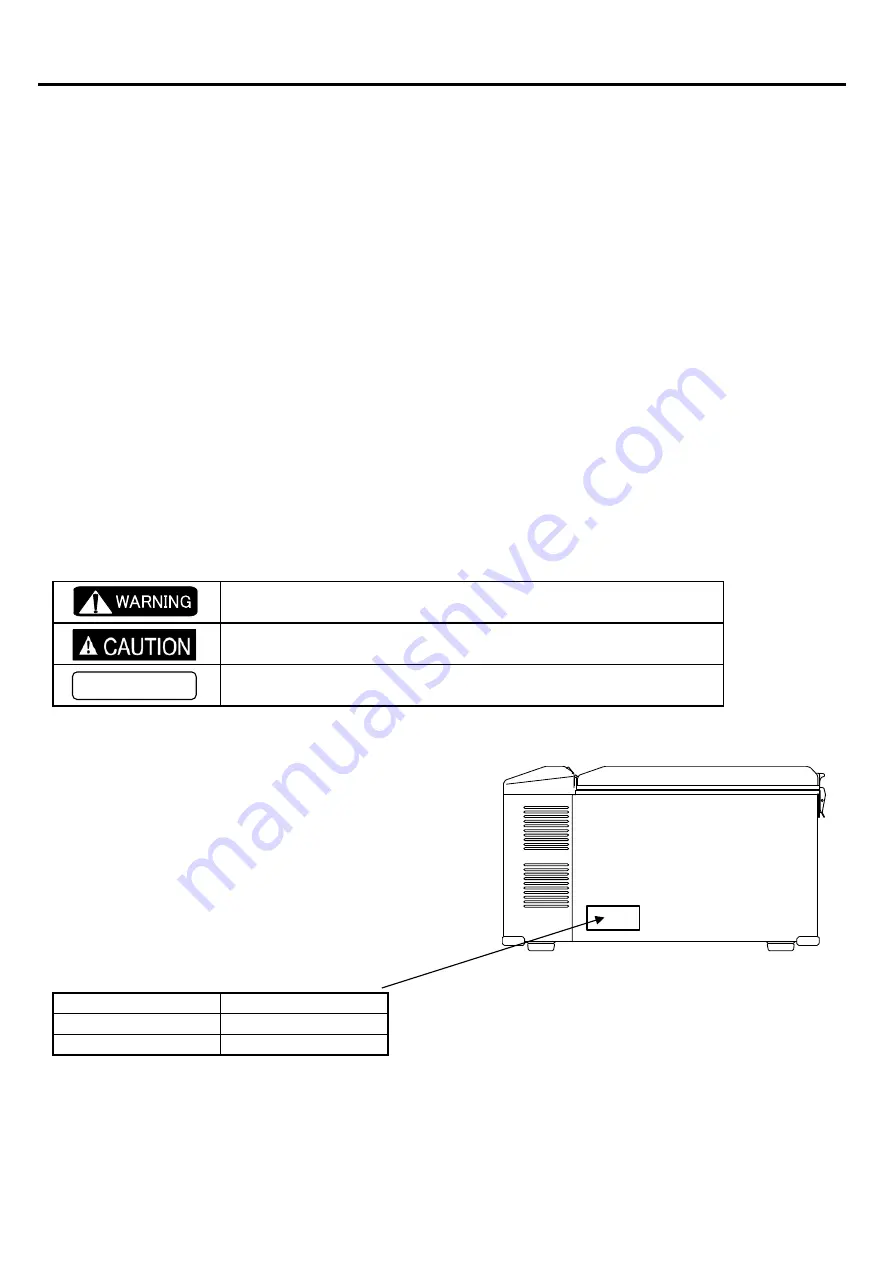

REFRIGERATOR CODE NUMBERS

・

This manual is compatible with described model in below.

Please check refrigerator model name and number in lable .

(Lable place as picture)

NUMBER

MODEL NAME

0642 032 0R12

MT35F-U1

0642 042 0R22

MT45F-U1

This service manual describes maintenance procedures for ENGEL refrigerator.

This manual is intended for repair engineers who are familiar with basics service skills and

knowledge for ENGEL refrigerator.

This manual does not guarantee correct maintenance when service is done by a non-skilled

worker without technical knowledge.

Note that the content of this booklet including product specifications is subject to change for

improvement without notice.

Always comply with the procedures, directions, and work tips in this booklet when

servicing the refrigerator.

To secure safe and correct servicing, read this manual thoroughly in advance and check

if there are protective equipment and appropriate tools and service parts ready as well

as technical skills necessary to perform servicing.

May lead to death or serious injury if failed to comply with this

precaution

May lead to injury if failed to comply with this precaution

Lead to failure of the refrigerator set or its components if failed

to comply with this precaution

WORK TIPS

Summary of Contents for 0642 032 0R12

Page 7: ... MT35F MT45F 3 PART NAME 4 ...

Page 20: ......