- 25 -

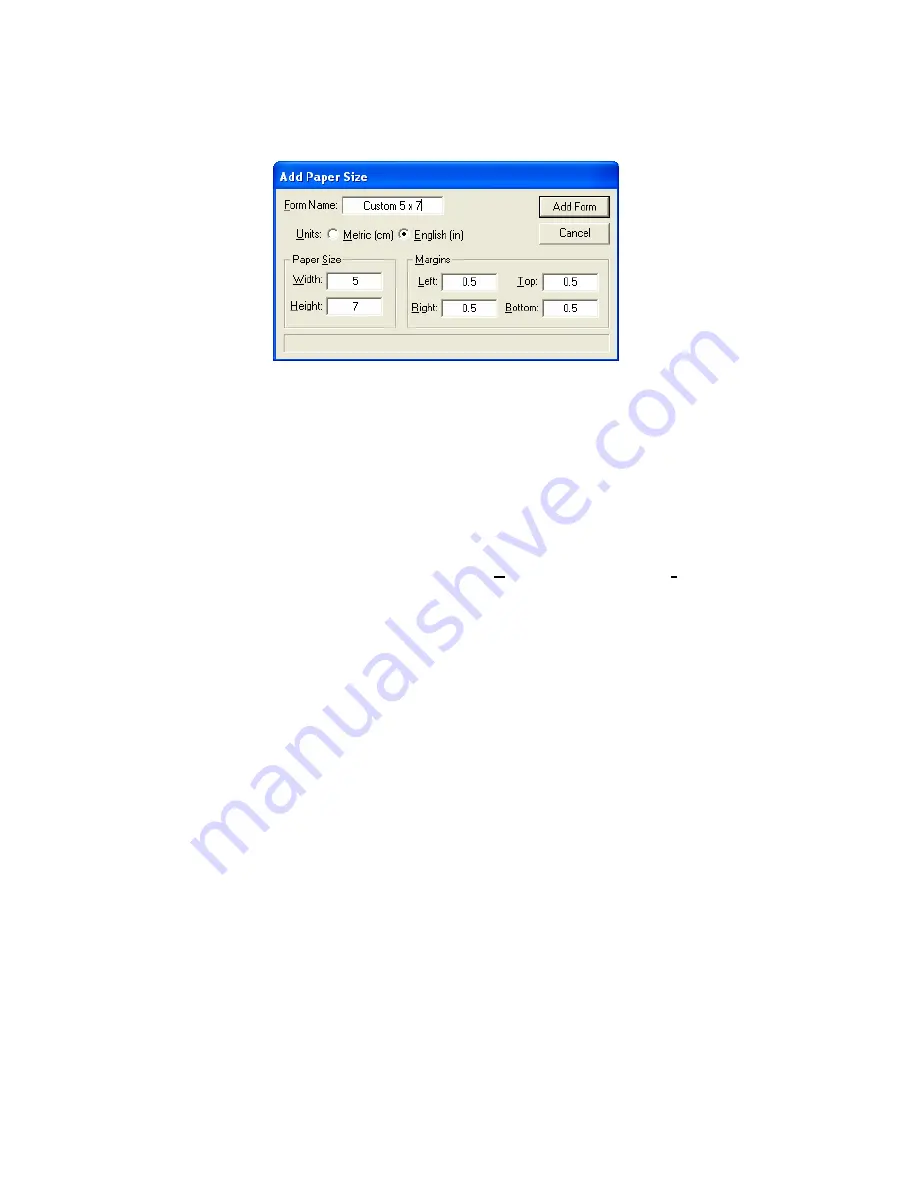

Insert the paper size and margins of the custom paper. Give the custom paper a name in the

Form Name box. Click on the Add Form button when done.

Note that after adding a custom paper size, the printing preferences dialog box must be closed

and reopened before the new paper size will show in the paper size drop down list.

Deleting and Modifying Custom Paper Sizes

The driver uses standard Windows Print Server forms for paper size definitions. These forms can

be added, deleted, and maintained using the standard Windows print server properties

configuration dialog.To access the Print Server Properties dialog open the Printer and Faxes

folder from the Windows control panel. Then select the

File -> Server Properties

menu item from

the printer folder. The

Forms

property sheet can be used to delete and modify form properties

Copies –

Sets the copy count for the number of prints to be made.

Summary of Contents for ChromaBlast

Page 21: ... 15 ...