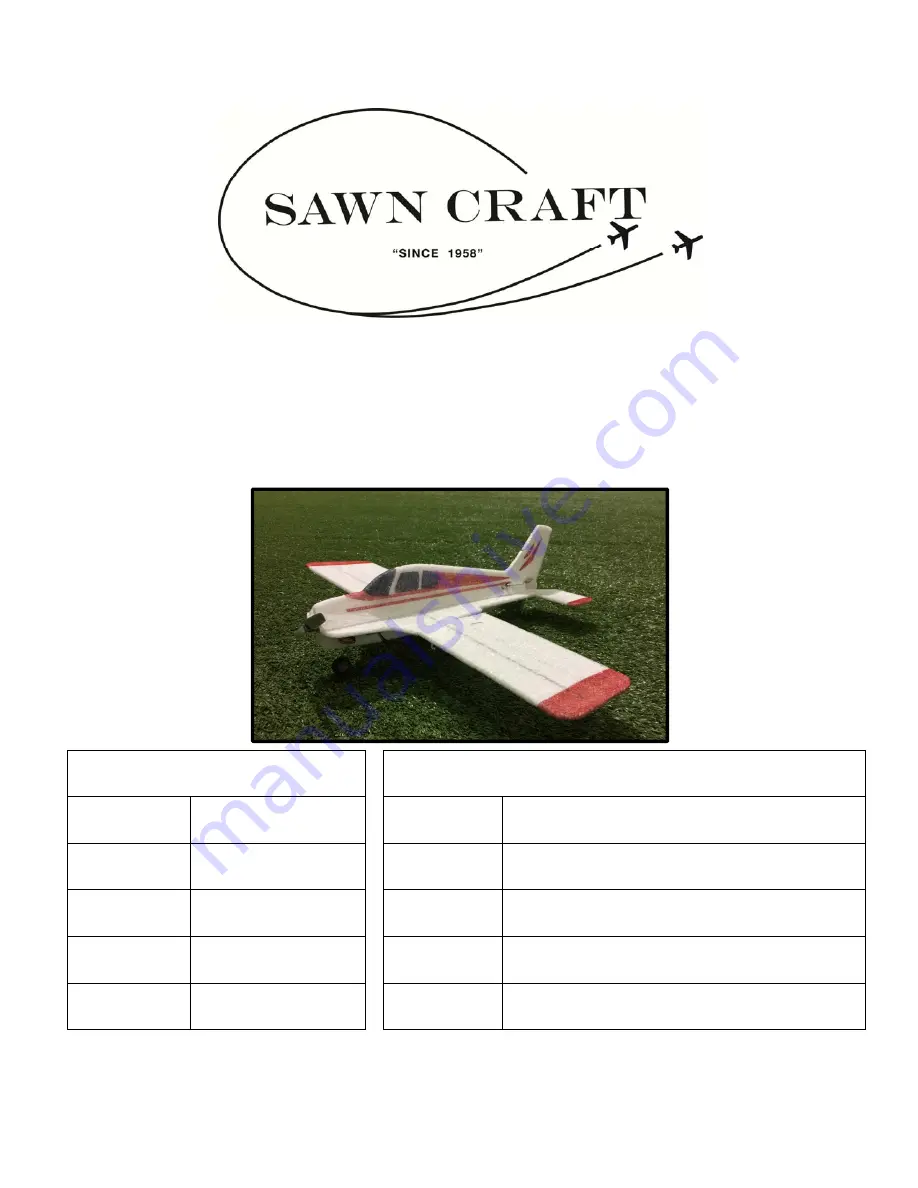

Cherokee 24

Assembly and Setup Manual

Specifications

Recommended Power System

Wingspan 24”

ESC

10A

Brushless

Overall Length

18.3”

Motor

40 to 50 watt out runner (14g)

Wing Area

133.9 in

2

Servo

4x

3.6g

Sub-Micro

Flying Weight

3.9oz / 111g

RX

6-Channel (4-ch minimum)

Intended Use

Indoor/Outdoor

Battery

180 to 300mAh 2S 7.4V 25C LiPo (or similar)

Revised 2016-10-19